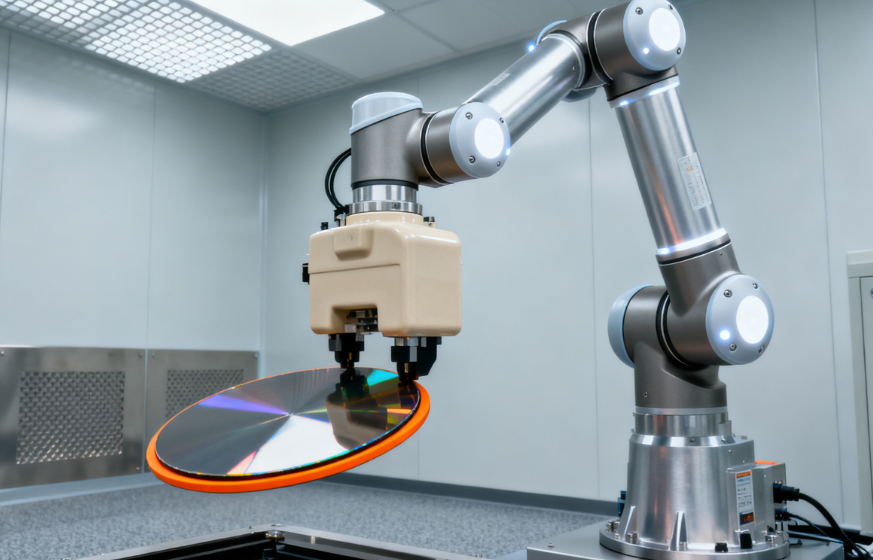

In today’s fast-evolving semiconductor industry, precision and reliability in wafer handling are more critical than ever. St.Cera Co., Ltd., a leading manufacturer of high-performance ceramic components, has introduced a new generation of precision ceramic end effectors designed specifically for 300 mm wafer processing. These innovative components improve equipment efficiency while maintaining the stringent quality standards required by modern fabs.

• Superior Material Performance

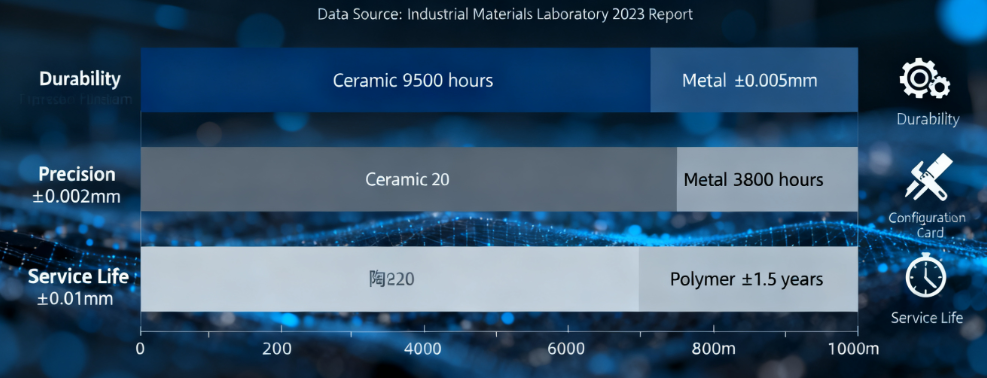

Crafted from high-purity aluminum oxide (Al₂O₃) ceramics, St.Cera’s end effectors deliver exceptional hardness, wear resistance, and dimensional stability. These properties allow the components to endure continuous operation in high vacuum and cleanroom conditions without deformation or contamination. The low coefficient of friction inherent to the ceramics reduces mechanical wear, extending the operational lifespan of robotic wafer-handling systems.

• Enhanced Precision and Stability

St.Cera’s ceramic end effectors maintain precise alignment during high-speed wafer transfer. Unlike traditional metal or polymer components that can expand or wear over time, precision ceramics ensure consistent performance and reduce the risk of wafer scratches or micro-damage. This capability helps semiconductor fabs achieve higher yields and maintain stable production quality.

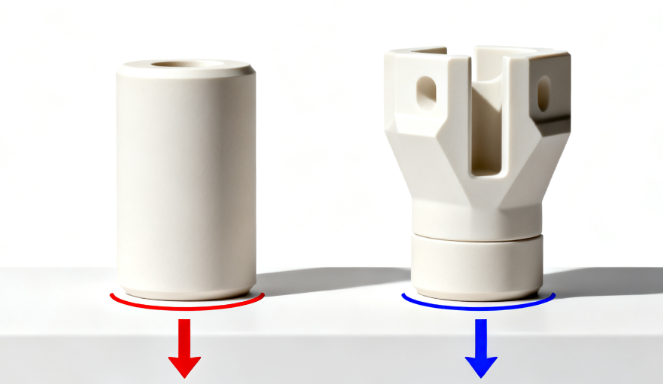

• Customization for Advanced Semiconductor Equipment

Recognizing the diverse needs of semiconductor manufacturers, St.Cera offers customizable ceramic end effectors. From complex geometries to thin-walled designs, each piece is engineered to meet tight tolerances and integrate seamlessly with existing robotic systems. This level of customization allows fabs to optimize production processes without sacrificing speed, precision, or reliability.

• Industry Impact and Future Outlook

The adoption of precision ceramic components in wafer handling reflects a wider industry trend. As wafer sizes increase and processing steps become more complex, the demand for durable, contamination-free, and high-performance materials grows. St.Cera’s end effectors combine these benefits, providing semiconductor manufacturers with advanced tools to enhance operational efficiency.

By leveraging the unique properties of ceramics, St.Cera is redefining 300 mm wafer handling, delivering both technological advancement and practical reliability. These solutions are set to play a crucial role in the next generation of semiconductor production worldwide.

Post time: Nov-11-2025