Why Choose Zirconia Ceramic End Effectors for Precision Applications

Table of Contents

- Overview of Zirconia Ceramic End Effectors in Precision Applications

- Key Properties of Zirconia Ceramic for Industrial Use

- Applications of Zirconia Ceramic End Effectors in Robotics

- Comparative Advantages of Zirconia vs. Traditional Materials

- Challenges and Limitations of Zirconia Ceramic End Effectors

- Future Trends in Zirconia Ceramic Technology for Precision Engineering

- FAQS

- Conclusion

- Related Posts

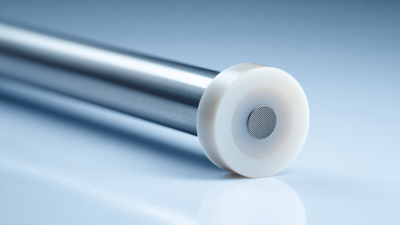

In the realm of precision applications, the choice of materials for end effectors can significantly influence the performance and reliability of robotic systems. Zirconia Ceramic End Effectors have emerged as a leading solution due to their exceptional properties that cater to the stringent demands of various industries, including medical and electronics manufacturing. As Dr. Emily Harper, a prominent expert in advanced materials at the Robotics Institute, emphasizes, “The unique combination of strength and biocompatibility in Zirconia Ceramic End Effectors makes them ideal for high-precision tasks where reliability is paramount.”

With their outstanding wear resistance and low thermal conductivity, Zirconia Ceramic End Effectors are increasingly adopted in precision applications where standard materials may fail. The inherent toughness of zirconia ceramics not only enhances the longevity of these components but also ensures they maintain their performance in challenging environments. As industries continue to seek out innovative solutions that push the boundaries of technology, the Zirconia Ceramic End Effector stands out as a sophisticated choice for engineers aiming for perfection in their robotic designs.

Overview of Zirconia Ceramic End Effectors in Precision Applications

Zirconia ceramic end effectors have gained significant traction in precision applications due to their unique properties that enhance performance and reliability. These advanced materials are characterized by their high strength, wear resistance, and an exceptional ability to withstand extreme temperatures, making them ideal for use in environments demanding high precision. According to a report by Market Research Future, the global demand for advanced ceramics, including zirconia, is projected to grow at a compound annual growth rate (CAGR) of 5.7% from 2020 to 2027, highlighting the increasing reliance on these materials in various industrial applications.

One of the most significant advantages of zirconia ceramic end effectors is their low friction coefficient, which facilitates smoother operation in robotic systems. Technical analyses indicate that their surface hardness can be up to six times greater than that of traditional materials. This property not only extends the lifespan of the end effectors but also contributes to higher efficiency and precision in handling delicate components. Moreover, studies have shown that zirconia’s biocompatibility and chemical inertness make them suitable for use in medical devices, where precision handling of sensitive materials is crucial. As industries continue to prioritize precision and durability, zirconia ceramic end effectors are becoming an integral component in achieving successful outcomes in various applications.

Why Choose Zirconia Ceramic End Effectors for Precision Applications

| Aspect | Details |

|---|---|

| Material Properties | High strength, excellent hardness, and minimal wear |

| Temperature Resistance | Can withstand high temperatures without deformation |

| Chemical Resistance | Resistant to corrosion and various chemicals |

| Maintenance | Low maintenance due to durable nature |

| Applications | Used in precision robotics, medical devices, and electronics |

| Cost Efficiency | Long-lasting materials reduce replacement costs over time |

| Customization | Can be tailored for specific shapes and functionalities |

Key Properties of Zirconia Ceramic for Industrial Use

Zirconia ceramic is gaining recognition in precision applications within various industrial sectors due to its exceptional properties. One of its primary advantages is its high strength and toughness, making it suitable for demanding operational environments. According to a report by the International Journal of Advanced Manufacturing Technology, zirconia ceramic exhibits a flexural strength ranging from 800 to 1200 MPa, significantly surpassing traditional materials used in similar applications. This durability ensures longevity and reduces the frequency of replacements, thereby cutting down operational costs.

Additionally, zirconia ceramics boast excellent wear resistance and low thermal conductivity, making them ideal for environments with extreme conditions. They can withstand high temperatures without compromising their structural integrity, which is crucial in industries such as aerospace and automotive. Data from the Ceramic Engineering and Science Proceedings highlights that zirconia can retain its strength even at temperatures exceeding 1000°C, positioning it as a reliable material for precision end effectors.

Tips: When selecting materials for precision applications, consider the specific environmental conditions such as temperature and mechanical stress. Ensure that the chosen material aligns with the operational parameters to maximize efficiency and lifespan. Proper surface treatment and design can also enhance the performance of zirconia ceramics, making them even more effective in specialized applications.

Applications of Zirconia Ceramic End Effectors in Robotics

Zirconia ceramic end effectors are increasingly being adopted in robotics due to their unique properties, which make them ideal for precision applications. In fields such as medical robotics, industrial automation, and delicate material handling, the high hardness and wear resistance of zirconia ceramics enable the creation of durable and efficient end effectors. This is particularly valuable in environments requiring sterile conditions, such as laboratory settings or surgical applications, where the non-reactive nature of zirconia minimizes the risk of contamination.

Moreover, the lightweight composition of zirconia ceramics enhances the agility of robotic systems, allowing for faster and more accurate movements. These end effectors can seamlessly interact with a variety of materials, from fragile components to rigid structures, without causing damage. The ability to produce complex geometries with high precision further expands their applicability, offering innovative solutions in fields such as electronics assembly and robotic grasping mechanisms. As the demand for precision in robotics continues to grow, zirconia ceramic end effectors are poised to play a crucial role in advancing automation technologies.

Comparative Advantages of Zirconia vs. Traditional Materials

Zirconia ceramic end effectors have emerged as a superior choice in precision applications due to their distinctive advantages over traditional materials. One of the most compelling benefits is zirconia's exceptional toughness and resistance to wear. According to a report by the International Journal of Advanced Manufacturing Technology, zirconia is approximately 50% tougher than alumina, a commonly used ceramic material. This increased durability results in a longer lifespan for end effectors, reducing maintenance costs and downtime in various industrial applications.

Furthermore, zirconia's low thermal and electrical conductivity makes it ideal for precision applications where temperature stability is critical. In a study published by the Journal of Materials Science, zirconia demonstrated a thermal conductivity 30% lower than that of traditional metal options, which mitigates thermal deformation and enhances precision in operations. Additionally, zirconia’s biocompatibility and chemical inertness broaden its application scope, particularly in the medical field, where materials need to minimize reactions with biological tissues. This combination of properties illustrates why zirconia is increasingly favored over traditional materials, facilitating improved performance and reliability in precision engineering tasks.

Challenges and Limitations of Zirconia Ceramic End Effectors

Zirconia ceramic end effectors are increasingly recognized for their advantages in precision applications, yet they face several challenges and limitations that may impact their effectiveness. One primary concern is the brittleness of zirconia, which, while offering high strength and wear resistance, can lead to catastrophic failure under high-stress conditions. Research indicates that zirconia has a fracture toughness that, although superior to other ceramics, remains significantly lower than metals, with a typical KIC value around 5-10 MPa√m, compared to steel, which can exceed 100 MPa√m. This limitation necessitates the careful design of end effectors to minimize stress concentrations and ensure reliability in demanding applications.

Another significant challenge in utilizing zirconia ceramic end effectors is their manufacturing process. The techniques employed to achieve the necessary precision and finish can be complex and costly. Industry reports highlight that the production of high-purity zirconia ceramics often involves advanced processes such as slip casting or injection molding, followed by high-temperature sintering. These methods can present challenges in achieving uniformity and consistency across batches, which is critical for precision applications. Furthermore, the relatively high cost of raw materials and processing can drive up the overall expense of devices utilizing zirconia end effectors, making them less accessible for applications with stringent budget constraints.

Future Trends in Zirconia Ceramic Technology for Precision Engineering

The future of precision engineering is increasingly leaning towards the adoption of zirconia ceramic technology, which offers unique benefits in a variety of applications. Recent industry reports indicate that the global ceramic materials market is projected to reach approximately $373 billion by 2026, with zirconia ceramics taking a notable share due to their superior mechanical properties and biocompatibility. The exceptional hardness, wear resistance, and thermal stability of zirconia make it an ideal candidate for precision applications, particularly in sectors such as aerospace, automotive, and medical devices.

In the realm of precision engineering, advancements in zirconia ceramic technology are leading to innovative designs and enhanced performance. For instance, ongoing research into the processing and modification of zirconia is expected to yield materials with improved fracture toughness and reliability. A study from a leading materials science institution has shown that incorporating additives in zirconia can enhance its properties even further, allowing for more complex geometries and tighter tolerances. This evolution positions zirconia ceramics not only as a material of choice but also as a catalyst for breakthroughs in precision applications, paving the way for next-generation technologies that demand the highest standards of performance and precision.

Why Choose Zirconia Ceramic End Effectors for Precision Applications

FAQS

: Zirconia ceramic is known for its high strength and toughness, with flexural strength ranging from 800 to 1200 MPa, which significantly exceeds that of traditional materials. This durability leads to lower operational costs due to reduced frequency of replacements.

Zirconia ceramics can withstand high temperatures above 1000°C while maintaining structural integrity, making them suitable for demanding environments like aerospace and automotive industries.

Zirconia ceramics exhibit excellent wear resistance, which is essential for longevity and reliability in precision applications, especially where components are subjected to significant mechanical stress.

They are favored due to their high hardness, wear resistance, and lightweight composition, which enhance the durability and agility of robotic systems, facilitating efficient and accurate movements.

Zirconia ceramic materials are particularly beneficial in sterile environments, such as laboratories and surgical settings, due to their non-reactive nature, which minimizes contamination risks.

They allow for seamless interaction with a variety of materials, from delicate components to rigid structures, without causing damage, and their capability to produce complex geometries enhances their utility in diverse robotic tasks.

When selecting zirconia ceramics, it's important to consider specific environmental conditions such as temperature and mechanical stress, along with ensuring proper surface treatment and design to enhance performance.

As demand for precision in robotics grows, zirconia ceramic materials are expected to play a crucial role in advancing automation technologies, particularly through the development of innovative solutions in various application fields.

Conclusion

Zirconia Ceramic End Effectors are increasingly recognized for their enhanced performance in precision applications across various industries. This overview delves into the unique properties of zirconia ceramics, including their high strength, durability, and resistance to wear, making them ideal for the demanding environment of robotics. These end effectors offer distinct advantages over traditional materials, such as improved precision and lower maintenance requirements, thereby optimizing operational efficiency.

However, the use of Zirconia Ceramic End Effectors is not without challenges. Issues such as brittleness and the complexities of manufacturing can limit their applicability in some scenarios. Despite these limitations, the future of zirconia ceramic technology looks promising, with ongoing advancements likely to expand their use in precision engineering. The continuous development in this field suggests a growing role for zirconia ceramics in shaping the future of industrial applications.

Related Posts

-

How to Choose the Right Bernoulli Ceramic End Effector for Your Automation Needs

-

Maximizing Performance in High Temperature Applications with Alumina Ceramics Supplier Innovations

-

How to Choose the Right Alumina Ceramic Roller for Your Industrial Needs

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

2025 Top 5 Alumina Ceramic Rods: The Ultimate Guide for Buyers

-

How to Enhance Your Workflow with Shadow Ring Inserts

Blog Tags: