Understanding Ceramic Dowel Pins and Their Applications?

Table of Contents

- What Are Ceramic Dowel Pins?

- Key Properties of Ceramic Materials

- Advantages of Using Ceramic Dowel Pins

- Common Applications of Ceramic Dowel Pins

- Comparative Analysis: Ceramic vs. Metal Dowel Pins

- Manufacturing Processes of Ceramic Dowel Pins

- Maintenance and Care for Ceramic Dowel Pins

- FAQS

- Conclusion

- Related Posts

Ceramic Dowel Pins are an essential component in precision engineering. These pins are made from durable ceramic materials, which provide high strength and corrosion resistance. According to a report by Research and Markets, the global ceramic components market is projected to reach $25.4 billion by 2025. This growth highlights the increasing demand for robust materials in various industries.

Applications of Ceramic Dowel Pins range from aerospace to medical devices. For instance, the aerospace sector values their lightweight nature and high temperature resistance. In contrast, the medical industry relies on their biocompatibility for surgical tools. However, implementing Ceramic Dowel Pins comes with challenges. Cost may deter smaller companies from adopting these advanced materials.

The versatility of Ceramic Dowel Pins makes them a favorite in many applications. Yet, engineers need to consider potential brittleness under certain conditions. Striking a balance between performance and durability is crucial. This ongoing development within the industry calls for a deeper understanding of material properties.

What Are Ceramic Dowel Pins?

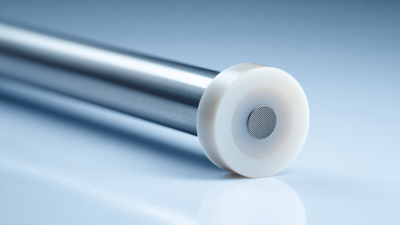

Ceramic dowel pins are precision components used in various industrial applications. They are crafted from advanced ceramic materials, providing a robust solution for alignment and securing parts together. These pins resist corrosion and wear, making them ideal for harsh environments. Their lightweight nature contributes to improved efficiency in machinery.

What makes ceramic dowel pins unique? Their smooth surface promotes easy installation and reliable performance. They can withstand high temperatures, essential in industries like aerospace and automotive. Moreover, their non-magnetic property prevents interference with electronic devices. However, their brittleness requires careful handling during installation.

In practice, not all are aware of potential shortcomings. For example, improper alignment during installation can lead to pin failure. Users must reflect on the maintenance routine, as wear occurs over time. When considering replacements, the choice of material is crucial. Some may overlook specific requirements, leading to inefficiencies. Careful thought is needed to ensure long-lasting performance and functionality.

Key Properties of Ceramic Materials

Ceramic materials exhibit unique properties that make them ideal for various applications. One prominent feature is their excellent hardness. Ceramics resist wear and tear, making them suitable for components that experience high friction. Another critical property is their resistance to high temperatures. This quality is essential in applications like aerospace and automotive industries. Ceramic dowel pins can operate effectively in extreme conditions.

Moreover, ceramics are chemically inert. They do not react with many substances, allowing them to be used in environments where contamination is a concern. However, despite these advantages, ceramics can be brittle. They may fracture under excessive stress. This limitation requires careful engineering in designs. Users must analyze the stress points to avoid breakage.

Additionally, the lightweight nature of ceramics is an appealing feature. Ceramics help reduce the overall weight of machinery. However, lightweight designs may sometimes sacrifice durability. It is crucial to balance these attributes while developing products. Overall, understanding ceramic materials’ properties can lead to more innovative applications.

Advantages of Using Ceramic Dowel Pins

Ceramic dowel pins have become increasingly popular in various industries due to their unique properties. These pins are made from advanced ceramic materials, which provide several advantages over traditional metal dowel pins. One significant benefit is their high resistance to corrosion. This means they can endure harsh environments without rusting. This durability extends the lifespan of machinery and components where they are used.

Another advantage is their lightweight characteristic. Ceramic dowel pins are much lighter than metal ones, reducing the overall weight of assembled parts. This is particularly beneficial in aerospace and automotive applications. Additionally, they have excellent thermal and electrical insulating properties. This feature can be crucial in electrical applications where preventing heat transfer is essential. However, the brittleness of ceramics should not be overlooked. Improper handling can lead to breakage, which may cause operational issues. Ensuring proper installation techniques are followed is vital to maximize their performance.

Furthermore, the cost of ceramic dowel pins can be higher than metal alternatives. While they offer distinct advantages, one must weigh the benefits against the investment. Some projects may not justify the expense if metal pins can suffice. It's essential to consider the specific application's needs. Understanding both the pros and cons can lead to better decision-making in selecting the right dowel pins.

Common Applications of Ceramic Dowel Pins

Ceramic dowel pins are gaining traction across numerous industries due to their unique properties. Commonly used in manufacturing, these pins excel in applications requiring high precision and stability. Their resistance to wear and corrosion makes them ideal for harsh environments. Reports indicate that the ceramic pin market is expected to grow by 7% annually, driven by technological advancements and the rising demand for durable components.

In aerospace, ceramic dowel pins provide excellent alignment for crucial components. They endure high temperatures and harsh chemicals, which ensures lasting performance. The automotive sector also benefits, particularly in engine assembly, where precision is paramount. Ceramic pins help reduce tolerances and improve overall quality.

Tips: Ensure proper installation. Misalignment can lead to functionality issues. Regular inspections can help identify wear early. Seek feedback from engineers to spot potential improvements. Continuous evaluation is key to optimizing the use of ceramic dowel pins in production.

Comparative Analysis: Ceramic vs. Metal Dowel Pins

Ceramic dowel pins offer unique advantages over their metal counterparts. They are lightweight and resistant to corrosion. This makes them suitable for various applications in harsh environments. In contrast, metal pins can rust and corrode, leading to potential failures. Ceramic pins maintain their integrity better under extreme temperatures. This can be crucial in applications requiring high-performance materials.

However, it's important to note that ceramic dowel pins can be more brittle. They may shatter under significant impact. This can pose challenges in certain settings where durability is critical. Alternatively, metal dowel pins, while heavier, provide more flexibility and strength in heavy-load applications. The choice between ceramic and metal should consider the specific requirements of the application.

The cost difference also plays a role in decision-making. Ceramic pins might cost more upfront. However, their longevity and lower maintenance requirements can lead to savings over time. It’s essential to weigh these factors carefully. Each material has its pros and cons. An informed decision can prevent future issues.

Manufacturing Processes of Ceramic Dowel Pins

Ceramic dowel pins are engineered components that offer precision and strength. The manufacturing process of these pins involves several key steps. Raw materials, often high-purity ceramics, are first selected. These materials must meet specific criteria for durability and performance.

Once the materials are chosen, they undergo a shaping process. This usually involves pressing or granulating the ceramic powder into desired forms. During this stage, achieving uniformity in size is crucial. Inconsistent sizes can lead to challenges in assembly and functionality. After shaping, the pins are sintered, which means they are heated to a high temperature. This process enhances their strength and stability.

After sintering, quality checks are vital. Measurement tools assess the dimensions of the dowel pins. Any deviations can affect their usability. Surface finishing often follows. This step can include grinding or polishing to ensure a smooth surface. Achieving a flawless finish can be tricky, as imperfections may arise. Ultimately, the manufacturing of ceramic dowel pins demands precision and attention. The balance between quality and efficiency can pose significant challenges for manufacturers.

Understanding Ceramic Dowel Pins and Their Applications

| Property | Description | Applications |

|---|---|---|

| Material | Alumina, Zirconia | Used in high-performance applications |

| Strength | High compressive strength, Low tensile strength | Automotive, Aerospace |

| Thermal Stability | Stable at high temperatures | Electrical insulators, Heat exchangers |

| Corrosion Resistance | Resistant to chemical attacks | Chemical processing industry |

| Manufacturing Process | Pressing, Sintering, Machining | Precision machinery components |

Maintenance and Care for Ceramic Dowel Pins

Ceramic dowel pins are crucial in various industries, known for their precision and durability. Proper maintenance is essential for maximizing their performance. Regular inspections are a must. Look for signs of wear or damage. Any chipping can lead to machining problems. According to a recent industry report, regular maintenance can extend the lifespan of these pins by up to 30%.

Tips: Always clean ceramic dowel pins after use. Use a soft cloth to remove dust and debris. Avoid abrasive materials. They can scratch the surface and reduce effectiveness.

Storing ceramic dowel pins correctly is also important. Store them in a designated place, away from heavy tools. Keep them dry and clean to prevent corrosion. Even minor mishaps in storage can lead to degradation. Reports suggest that improper storage can reduce a pin’s usability by nearly 40%.

Tips: Use designated containers for storage. Label them clearly to avoid mix-ups. This simple practice can save time and enhance efficiency. Evaluate your maintenance practices regularly to ensure they align with industry standards. This can help identify areas that need improvement and reinforce best care practices.

FAQS

: The guide aims to provide practical tips for improving personal productivity.

Self-reflection is key. Take a moment to analyze your daily routines and habits.

Try using a planner or digital calendar. Setting reminders can keep you on track.

Yes, breaks are essential. Short breaks rejuvenate your mind and enhance focus.

Identify your main distractions. Create a dedicated workspace to minimize interruptions.

Clear goals provide direction. Writing them down can increase accountability.

Regularly review accomplishments. Celebrate small wins to keep your motivation high.

Yes, overloading your to-do list can be counterproductive. Prioritize effectively.

Break tasks into smaller steps. This makes them feel more manageable and achievable.

Continuously seek feedback. Reflect on what works and what needs improvement.

Conclusion

Ceramic Dowel Pins are precision components made from ceramic materials, known for their excellent mechanical properties and resistance to wear and corrosion. Their key properties include high strength, lightweight, and thermal stability, making them ideal for diverse applications. The advantages of using Ceramic Dowel Pins over traditional metal pins include their ability to withstand extreme temperatures and environments, which enhances the longevity and reliability of mechanical assemblies.

Common applications of Ceramic Dowel Pins range from aerospace to electronics, where they serve critical roles in alignment and positioning. A comparative analysis reveals that while metal dowel pins may offer greater tensile strength, Ceramic Dowel Pins excel in applications requiring non-magnetic, chemically resistant components. The manufacturing processes of these pins involve advanced techniques that ensure precision and consistency. To maximize their lifespan, proper maintenance and care are essential, emphasizing the importance of understanding the unique properties of Ceramic Dowel Pins in various industrial settings.

Related Posts

-

How to Maximize Performance with a Ceramic Capture Ring in Your Processes

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

7 Best Ceramic Lift Pins for Enhanced Performance in Manufacturing

-

The Science Behind Ceramic Rods: Unveiling Their Role in Modern Technology

-

Exploring the Versatility of Alumina Ceramic Rings in Modern Technology Applications

-

Why Choose Aln Ceramic End Effectors for Your Automation Needs

Blog Tags: