The Ultimate Guide to Sourcing ESD Ceramic Support Arms for Enhanced Production Efficiency

Table of Contents

- Choosing the Right ESD Ceramic Support Arms: Key Specifications to Consider

- Comparative Analysis: ESD Ceramic Support Arms vs. Traditional Support Solutions

- Understanding ESD Material Properties: Impact on Production Efficiency

- Cost-Benefit Evaluation of Implementing ESD Ceramic Support Arms

- Best Practices for Integrating ESD Ceramic Support Arms in Production Lines

- Real-World Case Studies: Enhanced Productivity with ESD Support Solutions

- FAQS

- Conclusion

- Related Posts

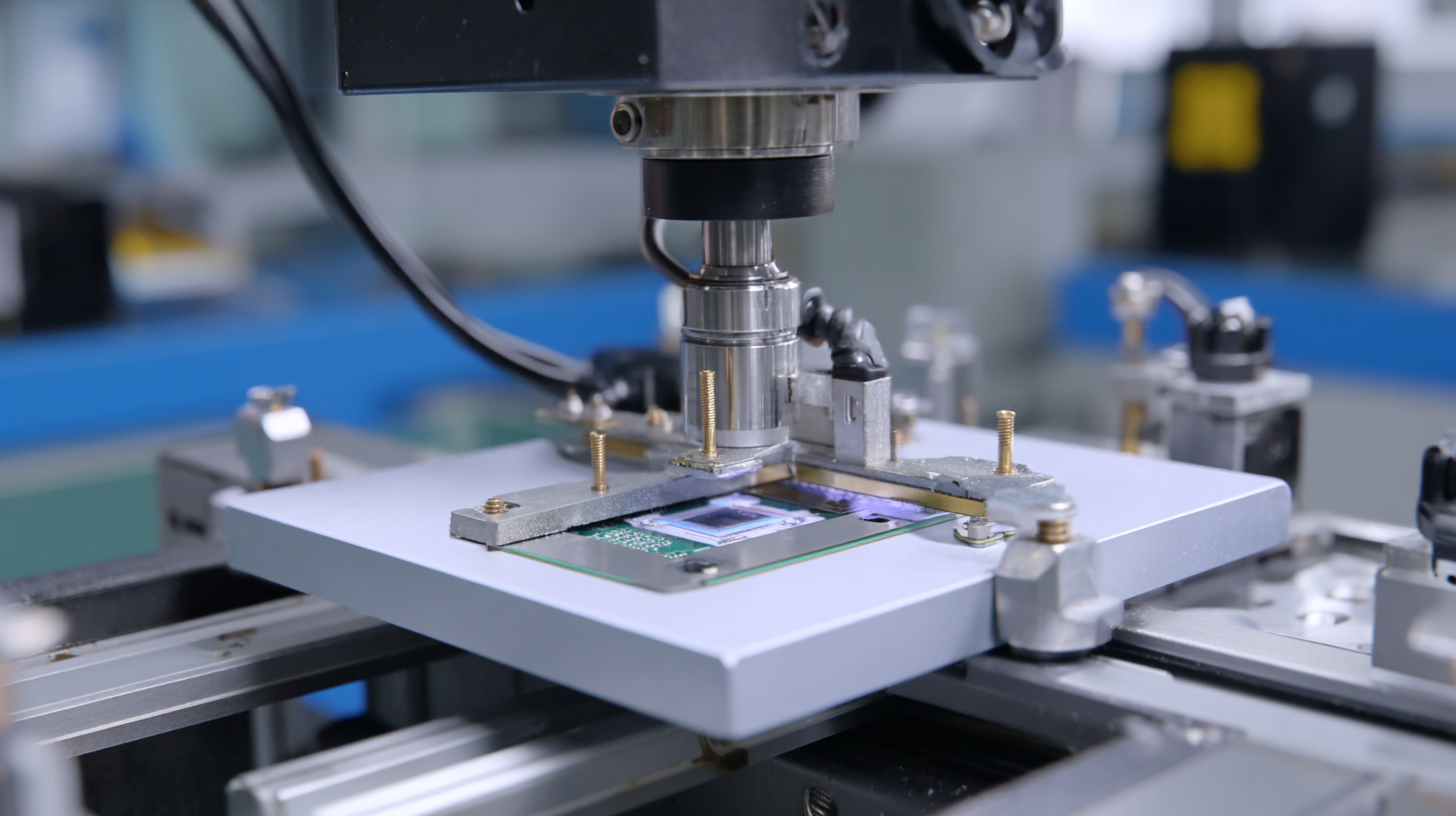

In today's fast-paced manufacturing environment, achieving enhanced production efficiency is essential for businesses looking to maintain a competitive edge. One key component in this pursuit is the use of ESD Ceramic Support Arms, which play a vital role in supporting various production processes while preventing static electricity interference. At ST.CERA CO., LTD., we specialize in precision ceramic manufacturing, leveraging our team of top-ranking experts and engineers to create high-quality ESD Ceramic Support Arms tailored to meet the specific needs of our clients. Our commitment to research and development, coupled with our expertise in manufacturing and marketing precision ceramic parts, positions us as a leader in this niche market. In this ultimate guide, we will explore the critical aspects of sourcing ESD Ceramic Support Arms and how they can significantly boost your production efficiency.

Choosing the Right ESD Ceramic Support Arms: Key Specifications to Consider

When choosing the right ESD ceramic support arms for your production line, it's essential to consider several key specifications that align with your operational needs. ESD, or Electrostatic Discharge, ceramic support arms are designed to prevent static electricity build-up, making them crucial in electronics manufacturing environments. Factors such as dielectric strength, thermal stability, and mechanical resilience play a pivotal role in ensuring that these components enhance production efficiency while maintaining the integrity of sensitive electronic parts.

At ST.CERA CO., LTD., our expertise in precision ceramic manufacturing positions us to provide insightful guidance in sourcing the best ESD ceramic support arms. With a team of top-ranking experts and engineers, we emphasize the importance of researching materials that offer superior electrical insulation and durability to withstand the rigors of industrial settings. By collaborating with us, you can ensure that your choice of support arms not only meets technical specifications but also aligns with your broader operational goals, resulting in streamlined processes and greater productivity in your manufacturing practices.

The Impact of ESD Ceramic Support Arms on Production Efficiency

Comparative Analysis: ESD Ceramic Support Arms vs. Traditional Support Solutions

When it comes to optimizing production processes, the choice of support arms plays a crucial role. This comparative analysis highlights the advantages of ESD (Electrostatic Discharge) ceramic support arms over traditional support solutions. ESD ceramic materials are designed to manage static electricity, reducing the risk of damage to sensitive electronic components. Unlike conventional support arms, which may create a static charge that can compromise product integrity, ESD ceramic arms provide a safe and effective means of enhancing production workflows.

Moreover, ESD ceramic support arms offer superior durability and resistance to wear and tear. They are less likely to corrode or degrade when exposed to chemicals commonly found in manufacturing environments. In contrast, traditional metal or plastic supports may require regular maintenance due to performance decline over time. This reliability translates into reduced downtime and maintenance costs, allowing manufacturers to achieve higher efficiency and productivity levels. In conclusion, the shift towards ESD ceramic support arms represents a significant advancement in support solutions, offering enhanced protection and longevity that traditional options simply cannot match.

The Ultimate Guide to Sourcing ESD Ceramic Support Arms for Enhanced Production Efficiency

| Feature | ESD Ceramic Support Arms | Traditional Support Solutions |

|---|---|---|

| Weight Capacity | Up to 25 kg | Up to 15 kg |

| Material Durability | High resistance to wear | Moderate resistance |

| Static Dissipation | Excellent | Poor |

| Temperature Resistance | Up to 150°C | Up to 100°C |

| Ease of Installation | Easy, tool-free | Requires tools |

| Cost | Moderate | Lower |

| Maintenance Frequency | Low | High |

Understanding ESD Material Properties: Impact on Production Efficiency

Understanding the properties of ESD materials is crucial for enhancing production efficiency in industries that rely on precision ceramics. ESD, or electrostatic discharge, is a significant concern in high-tech manufacturing environments. Selecting the right ceramic support arms made from ESD materials can significantly mitigate the risks of static electricity, which can damage sensitive electronic components. By utilizing advanced materials tailored for ESD applications, manufacturers can create reliable processes that ensure the safety and longevity of their products.

Understanding the properties of ESD materials is crucial for enhancing production efficiency in industries that rely on precision ceramics. ESD, or electrostatic discharge, is a significant concern in high-tech manufacturing environments. Selecting the right ceramic support arms made from ESD materials can significantly mitigate the risks of static electricity, which can damage sensitive electronic components. By utilizing advanced materials tailored for ESD applications, manufacturers can create reliable processes that ensure the safety and longevity of their products.

At ST.CERA CO., LTD., our focus on precision ceramic manufacturing positions us at the forefront of innovations in material science. Our expert team leverages cutting-edge research and the latest technological advancements to develop ESD ceramic components that meet the rigorous demands of modern production environments. Understanding the nuances of interface properties—especially at the microscopic level—further enhances our ability to produce ceramics with optimal performance characteristics and durability, ultimately leading to higher production efficiency. As the global market for materials continues to evolve, the integration of novel ESD properties will play a pivotal role in shaping the future of manufacturing excellence.

Cost-Benefit Evaluation of Implementing ESD Ceramic Support Arms

When considering the implementation of ESD ceramic support arms, a thorough cost-benefit evaluation becomes crucial for any production facility striving for enhanced efficiency. The initial investment in these advanced components may seem significant, but their long-term advantages often outweigh the upfront costs. ESD ceramic support arms are designed to minimize static buildup, thereby protecting sensitive electronic components during the manufacturing process. This added layer of protection can result in fewer defective products and costly rework, directly benefiting the bottom line.

Furthermore, ESD ceramic support arms contribute to improved operational workflows. Their lightweight and durable nature allows for easy adjustments and positioning, enhancing the flexibility of production lines. This agility can lead to reduced downtime during reconfigurations, ultimately increasing throughput. Additionally, by lowering the risk of electrostatic discharge, companies can foster a safer working environment for employees, thereby potentially reducing insurance and liability costs. This holistic evaluation underscores the importance of looking beyond initial costs and recognizing the broader financial and operational benefits of integrating ESD ceramic support arms into production systems.

Best Practices for Integrating ESD Ceramic Support Arms in Production Lines

Integrating ESD (Electrostatic Discharge) ceramic support arms into production lines can significantly enhance efficiency and reduce the risk of damage to sensitive electronic components. According to a report by IPC, the use of ESD protective equipment and materials can decrease defects in electronic assembly by up to 25%. The ceramic material provides superior static dissipation, ensuring that the delicate components remain safe from electrostatic discharge while facilitating smooth operations in high-production environments.

When incorporating ESD ceramic support arms, it’s essential to consider proper placement in your production layout. Positioning these arms strategically can optimize workflow and accessibility, leading to improved productivity. **Tip**: Conduct a layout analysis before installation to identify potential bottlenecks and ensure the support arms enhance rather than hinder the flow of materials and components.

Additionally, training personnel on the importance of ESD control can further elevate production standards. A study by the ESD Association indicated that 90% of companies that prioritize ESD training see a marked improvement in product reliability and worker efficiency. **Tip**: Implement regular workshops focusing on ESD risks and best practices to instill a culture of awareness and responsibility among the workforce.

Real-World Case Studies: Enhanced Productivity with ESD Support Solutions

In today's fast-paced manufacturing environment, the integration of

ESD (Electrostatic Discharge)

ceramic support arms plays a pivotal role in enhancing production efficiency.

ST.CERA Co., Ltd., a leader in precision ceramic manufacturing,

recognizes the critical impact of these innovative solutions. By utilizing ESD

support arms, companies can significantly reduce the risk of static electricity

disrupting delicate components, ultimately leading to smoother operations and

increased productivity.

Real-world case studies demonstrate the efficacy of ESD support solutions in various

industries. For instance, one of our clients reported a

30% decrease in downtime

after implementing our precision ceramic support arms. The reduction in static-related

incidents not only safeguarded sensitive electronic parts but also streamlined overall

workflow, showcasing how investing in quality ESD solutions can yield substantial returns.

ST.CERA's commitment to research and development

ensures that our products continually meet the evolving demands of the market, solidifying

our reputation as a trusted partner for enhancing operational performance.

FAQS

: ESD ceramic support arms are designed to prevent static electricity build-up, making them essential in electronics manufacturing environments for protecting sensitive components.

Dielectric strength is crucial because it indicates the material's ability to insulate against electrical discharges, helping to safeguard sensitive electronic parts during production.

ESD ceramic support arms manage static electricity effectively, reducing risks of damage to components, whereas traditional solutions may create static charges that could compromise product integrity.

ESD ceramic support arms are more durable and resistant to wear, corrosion, and chemical exposure compared to traditional metal or plastic supports, resulting in lower maintenance needs.

By utilizing ESD ceramic support arms, manufacturers can reduce downtime and maintenance costs, leading to streamlined processes and higher productivity.

Key specifications to consider include dielectric strength, thermal stability, and mechanical resilience to ensure compatibility with operational needs.

ST.CERA CO., LTD. offers expertise in precision ceramic manufacturing and can provide guidance on sourcing the best ESD ceramic support arms.

No, ESD ceramic support arms generally require less maintenance compared to traditional support arms, which may degrade over time and need regular upkeep.

The choice of materials impacts electrical insulation and durability, which are essential for ensuring the reliability and effectiveness of the support arms in industrial settings.

They provide a safe and effective means of managing static electricity, thus enhancing the protection and longevity of sensitive electronic components during manufacturing.

Conclusion

In today's fast-paced production environments, the integration of ESD Ceramic Support Arms is pivotal for enhancing operational efficiency. This guide outlines essential specifications to consider when selecting these support arms, emphasizing their advantages over traditional support solutions. By understanding the unique properties of ESD materials, manufacturers can significantly improve production efficiency while ensuring product safety in electrostatic-sensitive environments.

Additionally, the cost-benefit analysis reveals that investing in ESD Ceramic Support Arms not only streamlines processes but also promotes sustainable practices in production lines. Our company, St.Cera Co., Ltd., leverages advanced precision ceramic manufacturing capabilities to provide top-quality ESD solutions, ensuring that businesses can optimize their production workflows effectively. Through real-world case studies, we demonstrate the remarkable productivity enhancements achievable with ESD support solutions, reinforcing their value in modern manufacturing.

Related Posts

-

The Future of Innovative Ceramic Cylinder Solutions for Global Trade

-

Innovative Use Cases for Silicon Nitride Ceramic Sleeve in Modern Applications

-

How to Choose the Best ESD Wafer Arm for Optimal Semiconductor Processing Efficiency

-

Innovative Applications of Aluminum Nitride Plates in Modern Technology

-

2025 Trends in Advanced Ceramics: Innovative Solutions for Best Sic Ceramic Fork Applications

-

5 Reasons Why the Best 4 Inch Ceramic End Effector is a Game Changer

Blog Tags: