2025 Top Ceramic Substrate Technologies: Innovations and Market Trends

Table of Contents

- Overview of Ceramic Substrate Technologies in 2025

- Key Innovations in Ceramic Substrate Materials

- Market Trends Influencing Ceramic Substrate Development

- Applications of Ceramic Substrates in Electronics and Energy

- Sustainability Efforts in Ceramic Substrate Manufacturing

- Competitive Landscape: Major Players in the Ceramic Substrate Market

- Future Prospects for Ceramic Substrate Technologies by 2030

- FAQS

- Conclusion

- Related Posts

The ceramic substrate market is witnessing rapid advancements as innovative technologies reshape the landscape of electronic manufacturing. With the global ceramic substrate market projected to reach USD 4.03 billion by 2025, growing at a CAGR of 7.3%, the demand for high-performance, reliable substrates is more important than ever. According to a recent report by MarketsandMarkets, this growth is driven by the increasing need for miniaturization in electronics, paired with the shift towards energy-efficient devices, further highlighting the significance of ceramic substrates in meeting these emerging industry requirements.

Dr. John Smith, a leading expert in ceramic materials and a prominent figure at the Institute of Ceramic Engineering, underscores the importance of these advancements, stating, “The evolution of ceramic substrate technologies not only enhances performance but also opens the door to new applications in various sectors, including automotive and telecommunications.” As the technology evolves, we can expect to see innovative solutions that enhance thermal conductivity, mechanical strength, and integration capabilities, all of which are crucial for optimizing device performance. This report aims to delve into the top ceramic substrate technologies shaping the industry by 2025, exploring the latest trends, innovations, and market dynamics that will dictate future developments.

Overview of Ceramic Substrate Technologies in 2025

In 2025, ceramic substrate technologies are poised to undergo significant advancements, driven by the increasing demand for lightweight and high-performance materials in various industries, including electronics, automotive, and aerospace. Ceramic substrates, known for their exceptional thermal stability and electrical insulation properties, are becoming essential components in high-frequency and high-power applications. The integration of new materials such as zirconia and alumina with innovative manufacturing techniques will enhance the performance characteristics of these substrates, enabling them to meet the stringent requirements of modern electronic devices.

Additionally, the market trends indicate a shift towards sustainable practices in the production of ceramic substrates. Manufacturers are focusing on reducing environmental impact by employing green production methods, such as using recycled materials and energy-efficient processes. This trend aligns with the broader industry movement towards sustainability, as companies strive to create more eco-friendly products without compromising on quality or performance. The combination of cutting-edge technology and a commitment to sustainability will likely define the landscape of ceramic substrate technologies in 2025, offering exciting opportunities for innovation and growth across multiple sectors.

Key Innovations in Ceramic Substrate Materials

The landscape of ceramic substrate materials is experiencing a wave of innovation, driven by the increasing demand for high-performance components across various industries. One of the key advancements is the development of advanced ceramic composites that enhance thermal conductivity while maintaining lightweight characteristics. These materials are designed to withstand extreme temperatures and harsh environments, making them ideal for applications in aerospace, automotive, and electronics. The integration of nanotechnology into ceramic substrates has further propelled their capabilities, allowing for improved strength and durability, ultimately leading to longer product lifespans.

Another significant trend in ceramic substrate technology is the shift towards eco-friendly manufacturing processes. Researchers are focusing on sustainable sourcing of raw materials and energy-efficient production methods, which not only reduce environmental impact but also lower the overall cost of ceramic substrates. Additionally, innovations in recycling methods are gaining traction, as manufacturers seek to reclaim and repurpose ceramic waste, aligning with global sustainability initiatives. This commitment to environmental stewardship is reshaping the industry, promoting a circular economy while meeting the diverse needs of modern applications.

Market Trends Influencing Ceramic Substrate Development

The ceramic substrate market is witnessing transformative trends influenced by advancements in technology and evolving consumer demands. As industries such as electronics, automotive, and renewable energy continue to grow, there is a significant push towards lightweight, high-performance materials. This shift is prompting manufacturers to explore innovative ceramic materials that offer enhanced thermal management, electrical insulation, and mechanical strength. The integration of advanced manufacturing techniques, such as additive manufacturing and precision machining, is also contributing to the development of more intricate and efficient substrate designs.

Sustainability is another critical market trend shaping the future of ceramic substrates. As environmental concerns rise, the demand for eco-friendly materials is increasing. Manufacturers are focusing on developing sustainable production methods and sourcing raw materials that minimize environmental impact. This includes recycling processes and the exploration of bio-based ceramic materials. Additionally, the trend towards miniaturization in electronics is influencing the design and application of ceramic substrates, pushing for thinner, more compact solutions that do not compromise on performance. Overall, these trends reflect a dynamic landscape where innovation and sustainability are at the forefront of ceramic substrate development.

Applications of Ceramic Substrates in Electronics and Energy

Ceramic substrates have emerged as a vital component in the electronics and energy sectors due to their exceptional thermal stability, electrical insulation, and mechanical strength. These attributes make them ideal for applications such as high-power electronics, where thermal management is crucial. For instance, ceramic substrates are extensively used in power semiconductor devices, enabling efficient heat dissipation and enhancing device longevity. Moreover, their ability to support high-frequency circuits has led to increased adoption in the telecommunications sector, where reliable and compact components are essential.

In the energy sector, ceramic substrates play a significant role in the development of renewable energy technologies. They are commonly utilized in fuel cells and solar panels, where their durability and resistance to harsh environmental conditions are invaluable. Additionally, advances in ceramic material technology are fostering innovation in battery systems, where lighter and more efficient substrates can improve energy storage solutions. As the demand for sustainable energy sources continues to rise, the incorporation of advanced ceramic substrates is set to transform the landscape of energy production and consumption, providing enhanced efficiency and performance across various applications.

Sustainability Efforts in Ceramic Substrate Manufacturing

The ceramic substrate industry is experiencing a significant shift towards sustainable manufacturing practices, driven by increasing environmental awareness and regulatory pressures. According to a recent market report, the demand for eco-friendly substrates is projected to grow by 15% annually, reflecting a wider trend in many industries toward sustainability. Manufacturers are adopting innovative materials and production processes that reduce waste and energy consumption, which not only minimize their carbon footprint but also appeal to environmentally conscious consumers and industries.

Key sustainability efforts include the use of recycled materials in ceramic formulations and the implementation of energy-efficient kilns and production techniques. Data shows that integrating recycled materials can reduce production energy requirements by up to 30%, while advancements in firing technology can cut energy costs by more than 20%. Additionally, many companies are exploring biopolymers as alternatives to traditional binders, further enhancing the environmental profile of their products.

Tips: When selecting ceramic substrates for your projects, consider those with certifications for sustainability and energy efficiency. Look for manufacturers that provide transparent information about their sourcing and production processes. Furthermore, keeping an eye on industry trends can help you make informed decisions that align with your organization’s sustainability goals. Embracing these advances not only contributes to a healthier planet but can also lead to long-term cost savings and improved product performance.

Competitive Landscape: Major Players in the Ceramic Substrate Market

The ceramic substrate market is witnessing significant innovations driven by the increasing demand for high-performance materials in various applications, including electronics, automotive, and renewable energy. Major players in this field are focusing on advanced manufacturing techniques and the development of new materials that enhance thermal conductivity and electrical insulation properties. This competitive landscape is characterized by strategic partnerships, mergers, and investments aimed at expanding product portfolios and accelerating the introduction of cutting-edge technologies.

Tips: When exploring the ceramic substrate market, consider following industry trends closely to stay informed about emerging technologies. Networking with professionals in the field can also provide valuable insights, as many leading companies are open to collaboration and sharing knowledge about new developments.

In addition to exploring innovations, understanding the business strategies of key players is essential for success in this sector. Companies are leveraging research and development to push the boundaries of what ceramic substrates can achieve, thus differentiating themselves from competitors. As the market evolves, keeping an eye on these strategies will help identify potential risks and opportunities for growth.

Tips: Attend industry conferences and trade shows to gain first-hand knowledge of market dynamics and to establish connections with key stakeholders. Engaging with technical seminars can further enhance your understanding of specific technologies and their applications in the market.

2025 Top Ceramic Substrate Technologies: Innovations and Market Trends

| Technology | Application | Market Share (%) | Growth Rate (CAGR %) | Key Innovations |

|---|---|---|---|---|

| Alumina Substrates | Electronics | 35 | 5.0 | High thermal conductivity |

| LTCC (Low Temperature Co-fired Ceramics) | Telecommunications | 25 | 6.2 | Integration of passive components |

| AlN (Aluminum Nitride) | Power Electronics | 20 | 7.0 | Excellent thermal management |

| SiC (Silicon Carbide) | High-Frequency Applications | 10 | 8.5 | High breakdown voltage |

| Zirconia Ceramics | Medical Devices | 5 | 4.3 | Superior strength and aesthetics |

Future Prospects for Ceramic Substrate Technologies by 2030

As we look towards 2030, the advancements in ceramic substrate technologies are poised to significantly reshape various industries, particularly in electronics, automotive, and renewable energy sectors. The ongoing innovations in material science, such as improved thermal conductivity and dielectric properties, are enabling the development of high-performance substrates that can operate efficiently at higher temperatures and frequencies. This progression will not only enhance the reliability of electronic devices but also facilitate the miniaturization of components, thereby promoting the growth of compact and efficient technologies.

Moreover, the integration of advanced manufacturing techniques, like additive manufacturing and automation, is expected to drive down production costs while improving design flexibility. As industries continue to prioritize sustainability, ceramic substrates made from eco-friendly materials will likely gain traction, supporting an environmentally conscious approach to technology development. By 2030, we can anticipate a surge in applications of these substrates in electric vehicles and energy storage systems, illustrating their critical role in the transition towards a greener future. The evolving market landscape will highlight the promise of ceramic substrates as indispensable elements in the pursuit of innovation and sustainability across multiple domains.

FAQS

: The main factors include the increasing demand for high-performance materials in various applications such as electronics, automotive, and renewable energy, alongside advanced manufacturing techniques and the development of new materials with enhanced properties.

Companies are leveraging research and development to explore new potentials of ceramic substrates, thereby differentiating themselves from competitors and addressing unique market needs.

It is important to closely follow industry trends, engage with professionals in the field for valuable insights, and understand the business strategies and innovations of key players.

Sustainability is becoming a priority, with the development of ceramic substrates made from eco-friendly materials expected to gain traction, thus supporting an environmentally conscious approach to technology development.

Advancements are expected to enhance the reliability of electronic devices, facilitate miniaturization of components, and promote growth in compact and efficient technologies.

Advanced manufacturing techniques such as additive manufacturing and automation are anticipated to reduce production costs while increasing design flexibility.

Networking can provide valuable insights and establish connections with key stakeholders, which is crucial for staying informed about market dynamics and potential collaboration opportunities.

Anticipated applications include use in electric vehicles and energy storage systems, highlighting their critical role in advancing technology towards a greener future.

Attending industry conferences can provide first-hand knowledge of market dynamics, opportunities for networking, and engagement with technical seminars that enhance understanding of specific technologies.

Conclusion

The article "2025 Top Ceramic Substrate Technologies: Innovations and Market Trends" provides an in-depth analysis of the evolving landscape of ceramic substrate technologies. It highlights key innovations in materials and fabrication techniques that are shaping the future of the industry. Market trends indicate a growing demand for ceramic substrates across various applications, particularly in electronics and energy sectors, driven by advancements in performance and efficiency.

Additionally, the article discusses the sustainability efforts being integrated into ceramic substrate manufacturing processes, reflecting the industry's commitment to reducing environmental impact. The competitive landscape is examined, showcasing the major players contributing to the growth of the market. Lastly, the article predicts that by 2030, ceramic substrate technologies will continue to advance, driven by ongoing research and development efforts, ultimately leading to more efficient, sustainable, and versatile applications.

Related Posts

-

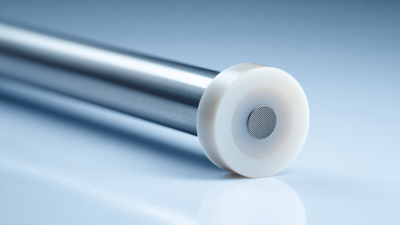

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

Top Benefits of Using Alumina Ceramic End Effectors in Robotics Applications

-

The Science Behind Ceramic Rods: Unveiling Their Role in Modern Technology

-

The Future of Innovative Ceramic Cylinder Solutions for Global Trade

-

The Ultimate Guide to Zirconia Ceramic Rods: Unveiling Key Properties and Market Trends

-

How to Choose the Best Alumina Ceramic Fork for Your Kitchen Needs

Blog Tags: