Essential Tips for Choosing Esd Ceramic End Effectors?

Table of Contents

- Understanding ESD and Its Impact on Manufacturing Processes

- Key Considerations for ESD Ceramic End Effectors in Electronics

- Material Selection: Properties of Ceramic for ESD Applications

- Design Features of ESD Ceramic End Effectors for Optimal Performance

- Performance Metrics: Measuring the Effectiveness of ESD Solutions

- Industry Standards: Compliance and Testing for ESD Components

- Cost-Benefit Analysis of Investing in ESD Ceramic End Effectors

- Maximizing Efficiency in Automation: The Role of ST.CERA Customized ESD Ceramic End Effectors

- FAQS

- Conclusion

- Related Posts

When you're choosing ESD Ceramic End Effectors, there are a few key things you wanna keep in mind. These parts are super important when it comes to handling delicate electronic materials, so you’ve gotta pick them carefully. The way they’re designed can really make or break how smooth your production line runs. Most companies aim to select end effectors that keep electrostatic discharge to a minimum — nobody wants surprises later on.

One common mistake I see is underestimating how much the material really matters. Picking the right ceramic can make all the difference in durability. But here’s the thing — not all ceramics are equally good at handling ESD. For example, choosing between alumina and zirconia isn’t as straightforward as it seems; you’ve gotta really think it through.

Then there’s the grip and flexibility of the end effectors. Sometimes, folks overlook how these small things can impact overall efficiency. Testing out prototypes can really show you if there are any design flaws — trust me, catching these early saves you a lot of headaches and money later on. Ultimately, understanding what your specific application needs will help you make smarter, more informed choices.

Understanding ESD and Its Impact on Manufacturing Processes

In modern manufacturing, electrostatic discharge (ESD) can pose serious risks. ESD occurs when static electricity discharges suddenly. This can damage sensitive electronic components. Understanding this phenomenon is crucial in any electronic assembly process. Without proper precautions, products can fail, leading to costly downtimes.

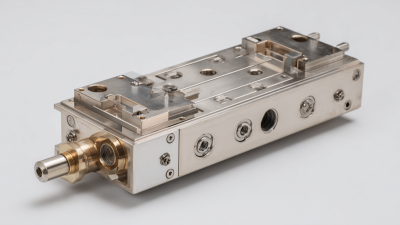

One essential aspect of ESD control is the design of end effectors. These are tools used in robotic systems. They must be made from materials that prevent the build-up of static electricity. Ceramic materials are popular choices, as they are both durable and ESD safe. However, not all ceramics are created equal. Some may still allow small charges to accumulate, which could cause damage.

Choosing the right ESD ceramic end effectors requires careful consideration. Look for specific properties, such as resistivity and surface conductivity. Testing them under real conditions can reveal their effectiveness. It's important to recognize that mistakes can happen. Sometimes, a product may not perform as expected. Continuous evaluation and adjustment are necessary to ensure optimal performance in the manufacturing environment.

Key Considerations for ESD Ceramic End Effectors in Electronics

When selecting ESD ceramic end effectors, it is crucial to consider several important factors. ESD, or electrostatic discharge, can seriously damage sensitive electronic components. Therefore, materials used must offer excellent conductivity. The ceramic used in these end effectors should effectively dissipate charges. Not all ceramics are created equal; their properties can vary significantly.

Another aspect to consider is the size and shape of the end effectors. They must be compatible with the components you handle. If they are too bulky, they may not fit into tight spaces. You might also overlook the need for precision. A well-designed end effector enhances operational efficiency.

Additionally, think about the durability of the materials. Some ceramics may crack or wear over time. Testing different types can reveal hidden weaknesses. Imperfections in design can lead to reduced performance. Observing replacements and repairs can provide valuable insights for future purchases. Reflection on these factors can improve your decision-making process significantly.

Essential Tips for Choosing ESD Ceramic End Effectors

This chart displays key considerations for ESD ceramic end effectors in electronics, focusing on five critical factors: Conductivity, Durability, Weight, Cost, and Temperature Resistance. The data reflects the importance of each factor on a scale of 0 to 100.

Material Selection: Properties of Ceramic for ESD Applications

Choosing the right materials for ESD ceramic end effectors is crucial. Ceramic offers high dielectric strength, making it ideal for electrostatic discharge (ESD) applications. With a dielectric constant typically around 6, ceramics can effectively insulate sensitive electronic components. This property helps in minimizing ESD risks during handling.

However, not all ceramics perform equally well. For example, alumina is a popular choice due to its excellent thermal stability and mechanical strength. It withstands intense handling and can last significantly longer than other materials. Research indicates that alumina can endure temperatures up to 1650°C. Yet, its brittleness can lead to challenges in specific applications. Perhaps some users might overlook the need for careful handling due to the material's resilience.

Another option is zirconia, known for its toughness. It has a lower electrical conductivity than alumina, making it less likely to harbor charge. A study reported that zirconia can reduce discharge rates by up to 20% compared to other materials. However, the higher cost of zirconia may deter some users. Balancing performance and budget is often necessary. Choosing ceramic for ESD applications requires weighing advantages against potential drawbacks. It is essential to analyze the specific requirements of each application for best results.

Essential Tips for Choosing ESD Ceramic End Effectors

| Property | Description | Importance in ESD Applications |

|---|---|---|

| Electrical Conductivity | The ability of ceramic to conduct electricity. | Essential for preventing static charge buildup. |

| Mechanical Strength | Resistance to mechanical stress and deformation. | Ensures durability in industrial applications. |

| Thermal Stability | Ability to maintain performance in varying temperatures. | Critical for environments with temperature fluctuations. |

| Chemical Resistance | Resistance to harsh chemicals and corrosion. | Important for longevity in diverse working environments. |

| Weight | The mass of the ceramic end effector. | Affects handling and automation performance. |

Design Features of ESD Ceramic End Effectors for Optimal Performance

When selecting ESD ceramic end effectors, you should focus on design features that enhance performance. Effective end effectors reduce the risk of electrostatic discharge, which can harm sensitive electronic components. Research indicates that more than 30% of electronic failures are attributed to ESD. A ceramic end effector, known for its durability, provides a good balance between weight and strength.

Consider the gripping mechanism. An optimal design uses a soft-touch material to minimize damage during handling. The gripping design should accommodate various shapes and sizes. For optimal outcomes, ensure the end effector’s tips can adjust to different surfaces. Data shows that this adaptability can improve productivity by up to 25%.

Tips for choosing the right features include assessing the material's conductivity. High-quality ceramics can provide better ESD protection. Check for certifications that validate the static dissipative properties. Regular evaluations post-deployment can identify performance gaps. Unexpected issues may arise with aging materials, affecting reliability. Pay attention to these details to ensure long-term effectiveness in your operations.

Performance Metrics: Measuring the Effectiveness of ESD Solutions

When selecting ESD ceramic end effectors, performance metrics are crucial. These metrics help determine the effectiveness of ESD solutions. One key measure is the discharge time. Faster discharge reduces the risk of static damage. Ideally, this should be under 1 second for most applications. Testing in real environments reveals discrepancies. Sometimes, performance in a lab differs greatly from production scenarios.

Another important metric is the contact resistance. It should be low enough to allow for quick static dissipation. Regular testing can help catch issues early. A resistance value of less than 10 ohms is generally ideal. However, not all materials achieve this. Some may surprise you with higher readings.

Diligently assess these metrics when choosing your end effectors. Gather data from multiple sources. This could mean conducting stress tests in various conditions. An imperfect fit might lead to inefficiencies. Adjustments may be required based on these results. Being attentive to these details ensures you make informed decisions.

Industry Standards: Compliance and Testing for ESD Components

Choosing ESD ceramic end effectors requires a solid understanding of industry standards. Compliance and testing are critical for ensuring reliability in electronic assembly processes. The International Electrotechnical Commission (IEC) lays out guidelines for ESD protective components. These standards help to minimize static discharge risks during handling.

Data from industry reports indicate that improper ESD management can lead to a loss of up to $4 billion annually in the semiconductor sector. Every year, thousands of components are damaged due to inadequate ESD protection. The failure rates of unprotected components often exceed 30%.

Conducting regular compliance testing is essential for ESD components. Tests should include resistance checks and discharge measurements. These assessments help identify potential weaknesses. Many companies overlook this step, which can lead to costly errors. Continuous reflection on testing practices is crucial. Improvement should be an ongoing goal in ESD management.

Cost-Benefit Analysis of Investing in ESD Ceramic End Effectors

When considering ESD ceramic end effectors, a cost-benefit analysis is crucial. These components are vital for many industries, particularly in electronics. They help prevent static build-up, ensuring the safety of sensitive components. However, their initial cost can be significant. Companies must weigh this against potential losses from damage due to static electricity.

Investing in ESD ceramic end effectors may lead to long-term savings. They often outlast traditional materials and require less frequent replacement. Still, the upfront expense can feel daunting. Assessing production needs is key. What happens if your processes are disrupted? The price of downtime might outweigh the cost of the end effectors.

Many companies overlook the importance of quality. Opting for cheaper alternatives might seem smart, but it could lead to higher costs down the line. Consider how often components fail. Frustration grows with repeated issues. Take time to reflect on your specific applications. Wrong choices can lead to significant setbacks. Investing wisely means looking beyond just the initial price tag.

Maximizing Efficiency in Automation: The Role of ST.CERA Customized ESD Ceramic End Effectors

In the ever-evolving landscape of semiconductor manufacturing, the demand for efficiency and reliability in automation processes is paramount. Customized End-effectors made from advanced ceramic materials play a crucial role in enhancing operational efficiency. The unique properties of ceramics—including high temperature resistance, corrosion resistance, abrasion resistance, and excellent insulation—make them ideal candidates for applications in various semiconductor production equipment subjected to extreme conditions. Reports indicate that the semiconductor industry is projected to grow at a compound annual growth rate (CAGR) of 10.8%, reaching a market size of over $1 trillion by 2025. This growth underscores the necessity for robust materials that can withstand demanding environments while delivering consistent performance.

Ceramic end-effectors designed specifically for automation tasks are instrumental in maximizing productivity while minimizing downtime. Their ability to operate effectively in environments characterized by high temperatures, vacuum, or corrosive gases ensures that semiconductor equipment can run smoothly over extended periods. Industry data reveals that equipment failures in semiconductor plants can lead to losses of up to $3 million per day, highlighting the immense cost-effectiveness of utilizing durable ceramic components. By investing in customized ceramics for automation, manufacturers can significantly boost efficiency, reduce operational risks, and ultimately contribute to the bottom line.

As operational demands in semiconductor fabrication continue to increase, the adoption of advanced ceramic materials in automation processes will likely become a strategic imperative. By leveraging the inherent properties of ceramic end-effectors, organizations can enhance their production capabilities, ensuring they remain competitive in a rapidly advancing industry. This focus on material innovation will pave the way for improved automation systems that meet the rigorous standards of modern semiconductor manufacturing.

FAQS

: The article aims to inform readers about a specific topic clearly.

Try to focus on key details presented in the text.

Yes, the article provides practical suggestions for various situations.

The content is based on knowledge until October 2023, so verify current relevance.

Yes, real-life examples are included to illustrate key points.

Reflection on different perspectives can enhance understanding and critical thinking.

The article wraps up with some thought-provoking insights on the topic.

Consider personal circumstances and adapt the advice for practical use.

Certain sections might require further elaboration to clarify complex ideas.

The tone is informative, yet it acknowledges different viewpoints throughout.

Conclusion

When selecting Esd Ceramic End Effectors, it is crucial to understand the implications of Electrostatic Discharge (ESD) on manufacturing processes. The unique properties of ceramic materials make them suitable for ESD applications, offering benefits such as durability and effective conductivity. Key considerations include not only material selection but also design features that enhance performance, ensuring that these end effectors meet industry standards for compliance and testing.

To assess the effectiveness of Esd Ceramic End Effectors, performance metrics must be established. A thorough cost-benefit analysis can highlight the long-term advantages of investing in these specialized components, making them integral in boosting productivity and safeguarding electronic components in manufacturing environments.

Related Posts

-

2025 Top Trends in Esd Ceramic End Effectors for Enhanced Automation Efficiency

-

Top 10 Esd Ceramic End Effectors for Improved Industrial Efficiency

-

Ultimate Guide to Sourcing the Best Sic Wafer Arm for Your Manufacturing Needs

-

The Ultimate Guide to Zirconia Ceramic Rods: Unveiling Key Properties and Market Trends

-

Unlocking Efficiency: How Vacuum End Effectors Revolutionize Robotics and Automation

-

What You Need to Know About 4'' Ceramic End Effectors: A Comprehensive Guide

Blog Tags: