Unlocking Precision in Robotics: Exploring the Edge Grip End Effector Technology

Table of Contents

- Understanding Edge Grip End Effector Technology in Robotics

- Key Mechanisms Behind Precision Handling in Robotic Systems

- Applications of Edge Grip Technology in Various Industries

- Comparative Analysis of Traditional vs. Edge Grip End Effectors

- Future Trends and Innovations in Robotic Grip Technology

- Challenges and Solutions in Implementing Edge Grip End Effectors

- FAQS

- Conclusion

- Related Posts

The advancement of robotics technology has significantly transformed various industries, necessitating more precise and efficient tools for automation. Among these innovations, the Edge Grip End Effector has emerged as a pivotal component, enhancing the ability of robotic systems to handle delicate and irregularly shaped items with remarkable accuracy. According to a recent industry report, the global robotics market is projected to reach $210 billion by 2025, with a substantial focus on fine-tuned manufacturing processes.

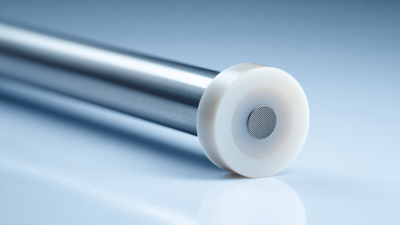

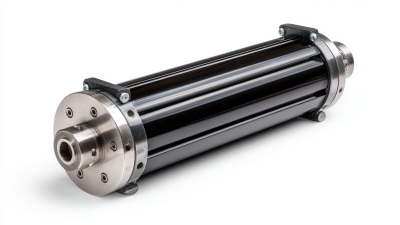

ST.CERA CO., LTD., as a leader in precision ceramic manufacturing, is ideally positioned to contribute to this growth. Our team of top-ranking experts and engineers is dedicated to developing cutting-edge solutions that incorporate Edge Grip End Effector technology, promoting higher productivity and precise material manipulation. By leveraging our core competencies in research and development, we aim to redefine the standards of efficiency within the robotics sector.

Understanding Edge Grip End Effector Technology in Robotics

Edge grip end effector technology is revolutionizing the field of robotics by enhancing precision and flexibility in various applications. This technology utilizes specialized gripping mechanisms that can securely hold objects along their edges, offering significant advantages in assembly, packaging, and material handling processes. According to a report by Markets and Markets, the global robotics end effector market is projected to reach $3.21 billion by 2026, growing at a CAGR of 12.6% during the forecast period. This growth is attributed to the increasing demand for automation in industries such as manufacturing and logistics.

The engineering behind edge grip end effectors allows for a more adaptive approach to different shapes and weights of materials. For instance, studies indicate that these devices can handle delicate items like glass or electronic components without damaging them, a critical requirement in sectors where precision is paramount. A survey conducted by the International Federation of Robotics (IFR) revealed that robots equipped with advanced end effectors have increased productivity in assembly lines by up to 30%. As industries continue to embrace automation, understanding and implementing edge grip technologies will be essential in achieving operational excellence and meeting market demands effectively.

Key Mechanisms Behind Precision Handling in Robotic Systems

The advancement of robotics has significantly hinged on the development of edge grip end effector technology, which facilitates precision handling in complex operational environments. According to a report by MarketsandMarkets, the global robotics market is expected to reach $210 billion by 2025, with a substantial part of this growth attributed to improving grasping mechanisms. Edge grip end effectors, designed to enhance the dexterity and adaptability of robotic systems, leverage innovative design principles that allow robots to handle a diverse range of objects with varying shapes and weights.

At the core of this technology are several key mechanisms, including adaptive gripping strategies and advanced sensor integration. A study by the Robotics Industries Association highlights that robots equipped with pressure-sensitive materials and tactile feedback systems can achieve a gripping accuracy of over 95%. This level of precision not only minimizes the risk of damage to fragile objects but also increases operational efficiency in industries such as manufacturing and logistics. As robots become more adept at complex precision handling tasks, businesses are positioned to benefit from reduced labor costs and improved productivity metrics.

Unlocking Precision in Robotics: Edge Grip End Effector Technology

Applications of Edge Grip Technology in Various Industries

Edge grip technology is revolutionizing the way precision robotics operate across various industries. This innovative end effector design allows robots to securely grasp objects without the need for traditional gripping methods, enhancing efficiency and adaptability in sectors such as manufacturing, logistics, and healthcare. The ability to handle a wider variety of shapes and sizes while ensuring minimal damage to delicate items positions edge grip technology as a game changer in automated systems.

In manufacturing, for instance, this technology enables robots to facilitate quicker assembly processes by easily interacting with different components. In logistics, robots equipped with edge grip end effectors can optimize package sorting and handling, significantly reducing operational costs. Moreover, in healthcare settings, these robotic systems can delicately manipulate medical instruments or assist in surgeries, showcasing the versatility and importance of edge grip technology across diverse applications. As industries continue to embrace automation, the adoption of such advanced technologies will play a crucial role in enhancing productivity and precision.

Comparative Analysis of Traditional vs. Edge Grip End Effectors

The robotics industry is experiencing a paradigm shift with the introduction of edge grip end effectors, which significantly enhance gripping capabilities compared to traditional methods. According to a recent report by MarketsandMarkets, the global robotics end effector market is projected to reach $1.35 billion by 2025, driven largely by innovations in gripping technologies. Traditional end effectors often rely on force-based gripping, which can be limiting when handling delicate or irregularly shaped objects. In contrast, edge grip technology utilizes specialized materials and designs that conform to the shape of the object, offering a more adaptable and efficient solution.

Comparative studies illustrate the superiority of edge grip end effectors in terms of efficiency and versatility. A research report by Technavio found that applications utilizing edge grip technology can achieve up to a 30% increase in operational speed. Furthermore, edge grip systems are better suited for complex tasks, reducing the risk of damage to sensitive components. With the robotics market advancing toward automation and the need for enhanced precision, the shift from traditional to edge grip end effectors is not just a trend but a necessity for future-proofing robotic applications across various industries.

Future Trends and Innovations in Robotic Grip Technology

The field of robotics is experiencing a transformative shift with advancements in grip technology, particularly in edge grip end effectors. According to a recent report by Markets and Markets, the global robotics market is expected to grow from $77 billion in 2020 to $168 billion by 2025, with a significant portion of this growth driven by innovative gripping systems. These systems are essential for improving the efficiency and precision of robotic applications across various industries, including manufacturing, healthcare, and logistics.

Innovations in robotic grip technology, such as adaptive grasping and soft robotics, are paving the way for more versatile and capable robots. A study published in the Journal of Field Robotics highlights that the integration of sensors and machine learning into gripping mechanisms has led to a 30% increase in operational effectiveness in automated picking processes. As robots evolve, the focus on developing end effectors that can handle a variety of shapes and weights will be critical in meeting the diverse demands of modern automation and enhancing the overall precision in tasks that require intricate handling.

Challenges and Solutions in Implementing Edge Grip End Effectors

The implementation of edge grip end effectors in robotics presents several challenges that require keen attention to overcome. A comprehensive report by the International Federation of Robotics (IFR) highlights that nearly 50% of companies experience difficulties with the adaptability of end effectors to varying shapes and materials, which can limit the efficacy of robotic systems in dynamic operational environments. Edge grip technology, designed to grasp objects by utilizing the edges for holding, encounters complexities in aligning with diverse geometries while maintaining the required force without damaging the items being handled.

Moreover, the complexity of integrating advanced sensing technologies into edge grip end effectors cannot be overlooked. According to a study by McKinsey, approximately 70% of robots implemented with inadequate sensory feedback fail to achieve optimal performance in object manipulation tasks. This gap underscores the necessity for improved sensor integration to enhance feedback mechanisms, ultimately leading to better precision in gripping operations. Continuous innovation in materials and design is critical, as it directly impacts the effectiveness and reliability of edge grip end effectors, propelling the robotics sector towards greater operational excellence.

FAQS

: Edge grip end effector technology refers to specialized gripping mechanisms that allow robots to securely hold objects along their edges, enhancing precision and flexibility in applications such as assembly, packaging, and material handling.

The robotics end effector market is projected to reach $3.21 billion by 2026 due to the increasing demand for automation in industries like manufacturing and logistics, growing at a CAGR of 12.6%.

Edge grip technology allows robots to handle delicate items, such as glass or electronic components, without causing damage, which is crucial for sectors requiring high precision.

Robots equipped with advanced end effectors can increase productivity in assembly lines by up to 30%, as reported by the International Federation of Robotics (IFR).

Key mechanisms behind precision handling include adaptive gripping strategies and advanced sensor integration, which facilitate the handling of diverse objects with varying shapes and weights.

Robots equipped with pressure-sensitive materials and tactile feedback systems can achieve gripping accuracy of over 95%, minimizing the risk of damage to fragile objects.

Nearly 50% of companies experience challenges related to the adaptability of end effectors to different shapes and materials, which can limit robotic system effectiveness in dynamic environments.

Proper sensor integration is crucial as approximately 70% of robots with inadequate sensory feedback fail to achieve optimal performance in object manipulation tasks, indicating the need for improved feedback mechanisms.

Continuous innovation in materials and design is essential for enhancing the effectiveness and reliability of edge grip end effectors, thereby driving greater operational excellence in the robotics sector.

The global robotics market is expected to reach $210 billion by 2025, largely due to advancements in grasping mechanisms and end effector technologies.

Conclusion

The article titled "Unlocking Precision in Robotics: Exploring the Edge Grip End Effector Technology" delves into the innovative Edge Grip End Effector technology, highlighting its mechanics and the advantages it offers over traditional end effectors. This technology enhances precision handling in robotic systems, making it instrumental across various industries such as manufacturing, logistics, and healthcare. The piece also discusses the comparative analysis between Edge Grip and conventional grip technologies, underlining the increased efficiency and adaptability of Edge Grip systems.

Moreover, the article addresses future trends and potential innovations in robotic grip technology, alongside the challenges faced in its implementation. As a company specializing in precision ceramic manufacturing, St.Cera Co., Ltd. is poised to contribute to this field by exploring the synergy between Edge Grip End Effectors and advanced ceramic materials, enhancing performance and durability in robotic applications.

Related Posts

-

Revolutionizing Automation with Advanced Gripper End Effectors for Seamless Operations

-

Challenges Faced with Esd Ceramic Arm in Manufacturing Processes

-

What You Need to Know About 4'' Ceramic End Effectors: A Comprehensive Guide

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

-

How to Choose the Best Alumina Ceramic Fork for Your Kitchen Needs

Blog Tags: