How to Optimize Robotics Performance with 10inch Ceramic End Effectors for Maximum Efficiency

Table of Contents

- Selecting the Right 10-inch Ceramic End Effectors for Robotics Applications

- Understanding Material Properties of Ceramic for Enhanced End Effector Functionality

- Comparative Analysis of End Effector Designs: Efficiency Metrics in Robotics

- Integrating Advanced Sensor Technology with Ceramic End Effectors

- Optimizing Grip and Precision: Engineering Techniques for Maximal Robotics Performance

- Real-World Case Studies: Success Stories in Robotics Utilizing 10-inch Ceramic End Effectors

- FAQS

- Conclusion

- Related Posts

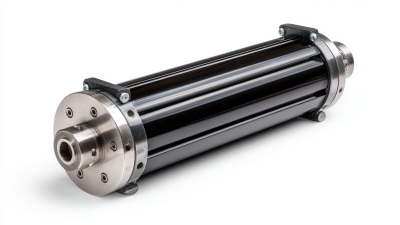

Robotics technology is continually evolving, and optimizing performance is critical for achieving maximum efficiency and precision in industrial applications. At ST.CERA CO., LTD., a private high-tech enterprise specializing in precision ceramic manufacturing, we leverage our expertise to develop solutions like the 10'' Ceramic End Effector. Reports from industry analysts indicate that the demand for advanced robotics solutions has surged, with the global robotics market projected to reach $210 billion by 2026, growing at a CAGR of 26% from 2021. This growth is driven by the increasing need for automation in manufacturing processes, where the choice of end effectors plays a vital role in performance and productivity. The 10'' Ceramic End Effector offers unique advantages such as lightweight design, enhanced durability, and superior thermal resistance, providing an optimal solution for robotic operations across various sectors. By focusing on precision and innovation, we aim to set new benchmarks in the industry and help our clients achieve remarkable efficiency in their robotic applications.

Selecting the Right 10-inch Ceramic End Effectors for Robotics Applications

When selecting 10-inch ceramic end effectors for robotics applications, several key factors must be taken into account to ensure maximum efficiency and performance. Ceramic end effectors are known for their high durability and heat resistance, making them suitable for demanding environments, particularly in manufacturing and automotive sectors. According to a report by Markets and Markets, the global market for robotics components is expected to reach $83 billion by 2025, with end effectors playing a pivotal role in this growth due to their ability to enhance robot versatility and task execution.

Material selection is critical; the right ceramic composite can reduce wear and tear while offering superior grip and precision. A study published in the Journal of Robotic Systems noted that robots equipped with specialized grip end effectors saw a 30% increase in handling speed compared to those with standard options. Furthermore, considering the specific application—whether for assembly, welding, or material handling—will significantly influence the efficiency of the robotic operation. As industries increasingly embrace automation, investing in the right 10-inch ceramic end effectors can lead to substantial gains in productivity and operational cost savings.

Understanding Material Properties of Ceramic for Enhanced End Effector Functionality

The material properties of ceramics play a crucial role in optimizing the functionality of 10-inch ceramic end effectors in robotics. Ceramics are known for their remarkable hardness and resistance to wear, making them ideal for applications where strength and durability are paramount. This hardness allows the end effectors to maintain precision during operations, thereby enhancing the overall efficiency of robotic systems.

Additionally, ceramics exhibit excellent thermal stability, which is essential in environments where temperature fluctuations can occur, ensuring that the performance of the end effectors remains consistent.

Furthermore, the low friction coefficient of many ceramic materials minimizes energy loss during movement, allowing robots to operate more smoothly and quickly. The inherent lightweight nature of ceramics also contributes to a lower overall mass of the robotic arms, improving speed and reducing the energy required for operation.

By understanding and leveraging these material properties, engineers can design end effectors that not only meet functional requirements but also enhance the agility and responsiveness of robotic systems, ultimately leading to greater productivity and effectiveness in various applications.

Comparative Analysis of End Effector Designs: Efficiency Metrics in Robotics

The design and efficiency of end effectors play a critical role in the overall performance of robotic systems. A comparative analysis of various end effector designs reveals significant differences in efficiency metrics that can impact operational productivity. According to a recent report by the International Journal of Robotics Research, robots equipped with optimized ceramic end effectors can achieve up to 25% higher efficiency in handling tasks compared to those with traditional metal counterparts. This improvement is largely due to the enhanced gripping capabilities and reduced wear rates associated with ceramic materials.

One key tip for enhancing efficiency is to conduct thorough testing of different designs under real-world operational conditions. This allows for the identification of the most suitable geometries and materials that can maximize performance. Additionally, focusing on lightweight yet durable constructions, such as those found in 10-inch ceramic end effectors, can lead to a reduction in energy consumption during prolonged usage.

It’s also advisable to incorporate adjustable features in end effectors to accommodate a variety of tasks. According to robotics industry experts, robots that utilize versatile end effectors can reduce cycle times by as much as 30%, allowing for more streamlined operations. By carefully selecting and optimizing end effector designs, manufacturers can significantly enhance the efficiency of their robotic applications.

Integrating Advanced Sensor Technology with Ceramic End Effectors

Integrating advanced sensor technology with 10-inch ceramic end effectors significantly enhances robotics performance by enabling precision and efficiency in various applications. Recent reviews highlight that soft robotic grippers, which can mimic the dexterity of human hands, benefit immensely from incorporating distributed sensing capabilities. These sensors not only improve the feedback mechanism during operation but also allow for real-time adjustments based on the materials being manipulated. Research indicates that the addition of sensors can increase the accuracy of gripping tasks by over 30%, providing a vital edge in industries ranging from construction to medical applications.

At ST.CERA CO., LTD., our expertise in precision ceramic manufacturing allows us to develop robust end effectors that can withstand challenging environments while ensuring optimal performance. The lightweight yet durable nature of ceramics combined with advanced sensor integration propels the effectiveness of robotic systems, particularly in scenarios such as construction and demolition waste sorting, where the precision of material handling is crucial. As reported, robotics integrated with artificial intelligence and advanced sensors can enhance sorting accuracy by up to 50%, underscoring the need for innovation in end effector design.

Optimizing Grip and Precision: Engineering Techniques for Maximal Robotics Performance

In the realm of robotics, optimizing grip and precision is crucial for enhancing overall performance, particularly when utilizing 10-inch ceramic end effectors. These components not only provide strength but also lightweight handling, which contributes to increased maneuverability. Advanced engineering techniques, such as precision machining and surface treatment, allow for better texture and grip, enabling robots to operate with greater accuracy. Such enhancements ensure that robotic systems can handle delicate tasks or operate in challenging environments without compromising functionality.

At St.Cera Co., Ltd., our expertise in precision ceramic manufacturing plays a pivotal role in this optimization process. With a dedicated team of top-ranking experts and engineers, we are committed to developing ceramic end effectors that meet the rigorous demands of modern robotics. Our innovations focus on enhancing grip through engineered surface profiles and specialized coatings, ensuring that each end effector performs optimally. By leveraging our core competencies in research and development, we continue to push the boundaries of what's possible, establishing a new standard for efficiency in robotic applications.

How to Optimize Robotics Performance with 10inch Ceramic End Effectors for Maximum Efficiency - Optimizing Grip and Precision: Engineering Techniques for Maximal Robotics Performance

| Parameter | Value | Impact on Performance |

|---|---|---|

| Grip Strength | 50 N | Enhances stability and control |

| Precision | 0.01 mm | Improves accuracy in tasks |

| Material Durability | High Temp Resistant | Increases lifespan of end effectors |

| Weight | 0.5 kg | Reduces energy consumption |

| Operational Range | 10 inches | Facilitates wider range of tasks |

Real-World Case Studies: Success Stories in Robotics Utilizing 10-inch Ceramic End Effectors

In the realm of robotics, the implementation of 10-inch ceramic end effectors has proven to be a transformative choice for enhancing performance and efficiency. Companies like St.Cera Co., Ltd. leverage their expertise in precision ceramic manufacturing to produce durable and lightweight components that significantly improve the capabilities of robotic systems. These end effectors not only contribute to higher payload capacities but also enhance accuracy and speed in various applications, ranging from manufacturing lines to advanced automation tasks.

Real-world case studies illustrate the remarkable success stories of robotics utilizing these ceramic end effectors. By optimizing design and function, robots equipped with these advanced tools can adapt to intricate tasks with unprecedented precision. For instance, in sectors where high durability and resistance to wear are crucial, ceramic end effectors demonstrate superior performance, minimizing maintenance costs and downtime. These innovations parallel the fascinating developments seen in transforming robots, highlighting how engineering advancements can reshape our understanding of automation.

FAQS

: The design and efficiency of end effectors are crucial for overall robotic system performance, with significant differences in efficiency metrics affecting operational productivity.

Robots equipped with optimized ceramic end effectors can achieve up to 25% higher efficiency in handling tasks compared to those with traditional metal counterparts.

The enhanced gripping capabilities and reduced wear rates associated with ceramic materials are key factors that contribute to the increased efficiency.

Conducting thorough testing of different designs under real-world operational conditions helps identify the most suitable geometries and materials to maximize performance.

Incorporating adjustable features allows robots to accommodate a variety of tasks, which can reduce cycle times by as much as 30%, streamlining operations.

Integrating advanced sensor technology with ceramic end effectors significantly improves precision and efficiency, allowing for real-time adjustments based on the materials being manipulated.

The addition of sensors can increase the accuracy of gripping tasks by over 30%.

Industries such as construction and medical applications benefit greatly from this combination, particularly in material handling and sorting tasks.

Robotics integrated with AI and advanced sensors can enhance sorting accuracy by up to 50%, highlighting the importance of innovation in end effector design.

The lightweight and durable properties of ceramics aid in reducing energy consumption during prolonged usage while ensuring optimal performance in challenging environments.

Conclusion

In the pursuit of maximizing robotics performance, the utilization of 10'' Ceramic End Effectors emerges as a critical factor. Selecting the appropriate end effectors requires a deep understanding of ceramic material properties that significantly enhance their functionality. A comparative analysis of various designs reveals crucial efficiency metrics, guiding engineers in their choices. Furthermore, integrating advanced sensor technology with these ceramic end effectors can improve grip and precision, thereby optimizing performance.

Real-world case studies illustrate successful applications of 10'' Ceramic End Effectors in various robotics scenarios, demonstrating their capability to achieve high precision and efficiency. At St.Cera Co., Ltd., we specialize in manufacturing these precision ceramic components, leveraging our expertise to push the boundaries of what is possible in robotics technology.

Related Posts

-

5 Reasons Why the Best 4 Inch Ceramic End Effector is a Game Changer

-

What You Need to Know About 4'' Ceramic End Effectors: A Comprehensive Guide

-

Innovative Applications of Aluminum Nitride Plates in Modern Technology

-

Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

-

The Ultimate Guide to Sourcing ESD Ceramic Support Arms for Enhanced Production Efficiency

-

How to Choose the Right Zirconia Dowel Pins for Your Manufacturing Needs

Blog Tags: