How to Maximize the Performance of Your Ceramic Cylinder in Industrial Applications

Table of Contents

- Understanding the Material Properties of Ceramic Cylinders for Optimal Performance

- Key Design Considerations for Ceramic Cylinders in Industrial Settings

- Effective Maintenance Practices to Enhance Ceramic Cylinder Longevity

- Choosing the Right Manufacturing Techniques for Ceramic Cylinder Production

- Optimizing Thermal and Mechanical Load Conditions in Industrial Applications

- Innovative Coating Solutions to Improve Ceramic Cylinder Performance

- FAQS

- Conclusion

- Related Posts

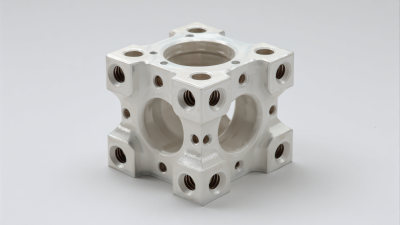

In the rapidly evolving landscape of industrial applications, the performance of components such as the Ceramic Cylinder plays a pivotal role in ensuring efficiency and longevity. St.Cera Co., Ltd., a private high-tech enterprise renowned for its expertise in precision ceramic manufacturing, is at the forefront of this innovation. Our dedicated team of top-ranking experts and engineers specializes in the research and development of high-performance Ceramic Cylinders tailored to meet the demanding needs of various industries. By leveraging advanced manufacturing techniques and state-of-the-art materials, we aim to maximize the operational effectiveness of Ceramic Cylinders, contributing significantly to the overall success of industrial operations. This guide will explore strategies and best practices that can enhance the performance of your Ceramic Cylinder, ensuring it delivers the reliability and durability required in today's competitive market.

Understanding the Material Properties of Ceramic Cylinders for Optimal Performance

Ceramic cylinders are increasingly popular in various industrial applications due to their unique material properties, such as high temperature resistance, chemical stability, and excellent wear resistance. According to a report by the Society of Materials Science, ceramics can withstand temperatures up to 1500°C without significant deformation, making them ideal for high-heat environments. Additionally, their low thermal conductivity contributes to energy efficiency in applications like automotive engines and aerospace components.

To maximize the performance of ceramic cylinders, it is crucial to understand their mechanical properties. For instance, the compressive strength of alumina ceramics can reach 400 MPa, providing robustness in demanding conditions. However, their brittleness poses a challenge in design and application.

**Tips for Optimal Performance:**

1. **Proper Handling:** Always handle ceramic cylinders with care, as they can be susceptible to chipping and cracking. Use appropriate protective gear and handling tools.

2. **Regular Inspections:** Conduct regular inspections for wear and tear. This proactive approach can prevent unexpected failures and prolong the service life of the cylinders.

3. **Temperature Management:** Maintain optimal operating temperatures to avoid thermal shock. Gradual heating and cooling can help ensure the longevity of the ceramic materials in service.

How to Maximize the Performance of Your Ceramic Cylinder in Industrial Applications - Understanding the Material Properties of Ceramic Cylinders for Optimal Performance

| Property | Description | Value | Importance in Application |

|---|---|---|---|

| Compressive Strength | Maximum load per unit area before failure | 400-600 MPa | Critical for withstand pressure applications |

| Thermal Conductivity | Ability to conduct heat through the material | 20-30 W/(m·K) | Important for thermal management in high-temperature applications |

| Density | Mass per unit volume of the ceramic | 2.5-3.0 g/cm³ | Affects weight and strength in applications |

| Flexural Strength | Strength when subjected to bending forces | 50-120 MPa | Essential for durability under mechanical loading |

| Thermal Expansion Coefficient | Rate of expansion when subjected to temperature changes | 5-10 x 10⁻⁶ /°C | Critical for maintaining shape in thermal cycling applications |

Key Design Considerations for Ceramic Cylinders in Industrial Settings

When designing ceramic cylinders for industrial applications, several key considerations can significantly enhance performance. First and foremost, the choice of raw materials is crucial. High-quality ceramic compounds should be selected based on their mechanical strength, thermal stability, and resistance to chemical corrosion. This selection directly influences the durability and lifespan of the ceramic cylinders, especially in harsh operating environments where exposure to extreme temperatures or corrosive substances is common.

Another important design aspect is the cylinder's geometry. Optimizing dimensions and wall thickness can improve stress distribution and thermal conductivity, which is essential for applications requiring efficient heat management. Additionally, incorporating features such as surface treatments or coatings can enhance wear resistance and reduce the likelihood of crack propagation. These design strategies not only contribute to the overall efficiency of the ceramic cylinder but also ensure reliable operation in demanding industrial settings.

Effective Maintenance Practices to Enhance Ceramic Cylinder Longevity

To enhance the longevity of ceramic cylinders used in industrial applications, effective maintenance practices play a crucial role. Regular inspections are essential to identify any signs of wear or damage. This proactive approach allows for timely repairs before small issues escalate into major problems. Additionally, ensuring that the cylinders are free from contaminants during operation can significantly reduce wear. Implementing proper cleaning protocols, including using non-abrasive materials, helps maintain the integrity of the ceramic surface.

To enhance the longevity of ceramic cylinders used in industrial applications, effective maintenance practices play a crucial role. Regular inspections are essential to identify any signs of wear or damage. This proactive approach allows for timely repairs before small issues escalate into major problems. Additionally, ensuring that the cylinders are free from contaminants during operation can significantly reduce wear. Implementing proper cleaning protocols, including using non-abrasive materials, helps maintain the integrity of the ceramic surface.

Another key practice is to monitor operating conditions closely. Excessive temperatures and pressure can adversely affect the performance of ceramic cylinders. Maintaining optimal operating parameters within recommended limits ensures that the material performs effectively throughout its lifespan. Furthermore, utilizing proper handling techniques during installation and maintenance can prevent accidental damage. Training staff on these protocols enhances awareness and promotes a culture of care, ultimately extending the life of ceramic cylinders in demanding industrial settings.

Choosing the Right Manufacturing Techniques for Ceramic Cylinder Production

When it comes to maximizing the performance of ceramic cylinders in industrial applications, choosing the right manufacturing techniques is crucial. The production methods employed can significantly influence the material properties, durability, and functionality of the final product. According to a recent market report by Grand View Research, the global ceramics market is projected to reach USD 370 billion by 2024, highlighting the growing demand for high-performance ceramic components across various industries.

One essential technique is the selection of appropriate forming methods such as slip casting, pressing, or injection molding. Each method offers distinct advantages that can cater to specific application requirements. For instance, slip casting is particularly effective for achieving complex shapes and high dimensional accuracy, while isostatic pressing can enhance density and mechanical strength. A study by the American Ceramic Society indicates that optimizing the forming technique can lead to mechanical strength increases of up to 25%, thereby directly impacting the reliability of cylindrical components under operational stresses.

In addition, the choice of raw materials plays a critical role in achieving desired performance characteristics. Using high-purity alumina or zirconia can significantly improve wear resistance and thermal stability. Research published in the Journal of the European Ceramic Society has shown that ceramic cylinders produced with advanced materials can endure temperatures exceeding 1,500°C while maintaining structural integrity, making them ideal for demanding industrial environments. By prioritizing the right manufacturing techniques and materials, manufacturers can enhance the longevity and efficacy of ceramic cylinders in diverse applications.

Optimizing Thermal and Mechanical Load Conditions in Industrial Applications

In industrial applications, the optimization of thermal and mechanical load conditions is critical for maximizing the performance of ceramic cylinders. To effectively manage thermal loads, it’s essential to ensure uniform heat distribution and minimize thermal gradients. This can be achieved by selecting appropriate materials that have excellent thermal conductivity and temperature stability. Implementing advanced cooling systems could further enhance heat dissipation, preventing thermal stresses that can lead to premature failure of the ceramic components.

Mechanical load conditions also play a fundamental role in the performance of ceramic cylinders. Ensuring proper alignment and support during installation can mitigate uneven stress distribution. Engineers should consider employing finite element analysis (FEA) during design and testing phases to predict how the ceramic will behave under various loading conditions. Additionally, the choice of operational parameters such as pressure and speed must be calibrated to align with the material’s mechanical limits, preventing catastrophic failure and extending the operational lifespan of the cylinders. By meticulously optimizing both thermal and mechanical conditions, industries can significantly enhance the reliability and efficiency of their ceramic components.

Innovative Coating Solutions to Improve Ceramic Cylinder Performance

Innovative coating solutions play a vital role in enhancing the performance of

ceramic cylinders, particularly in demanding industrial applications.

These coatings provide critical benefits, including improved wear resistance, enhanced

thermal stability, and reduced friction. Advanced materials such as

zirconia and alumina-based coatings can significantly extend the

lifespan of ceramic components, enabling them to withstand harsh environments and repetitive

stress conditions that would typically lead to early failure.

In addition to physical durability, innovative coatings can also improve the surface properties

of ceramic cylinders. For instance, hydrophobic or

oleophobic coatings can be applied to minimize moisture retention and reduce

contamination, while specialized thermal barrier coatings help manage

temperature extremes. By integrating these coatings into the design and production of ceramic

cylinders, manufacturers can optimize operational efficiency and reliability, ultimately leading

to cost savings and enhanced performance in a wide range of

industrial uses.

FAQS

: Ceramic cylinders are known for their high temperature resistance, chemical stability, and excellent wear resistance, making them suitable for various industrial applications.

Ceramics can withstand temperatures up to 1500°C without significant deformation, making them ideal for high-heat environments.

The compressive strength of alumina ceramics can reach 400 MPa, providing robustness in demanding conditions.

Proper handling is important because ceramic cylinders can be susceptible to chipping and cracking; appropriate protective gear and handling tools should be used.

Conducting regular inspections for wear and tear can prevent unexpected failures and prolong the service life of ceramic cylinders.

It is crucial to maintain optimal operating temperatures and avoid thermal shock by implementing gradual heating and cooling.

Common manufacturing techniques include slip casting, pressing, and injection molding, each with distinct advantages for specific application requirements.

Choosing high-purity alumina or zirconia can significantly improve wear resistance and thermal stability, enhancing the performance of ceramic cylinders.

Optimizing the forming technique can lead to mechanical strength increases of up to 25%, directly influencing the reliability of cylindrical components under operational stresses.

The global ceramics market is projected to reach USD 370 billion by 2024, indicating a growing demand for high-performance ceramic components.

Conclusion

In the article "How to Maximize the Performance of Your Ceramic Cylinder in Industrial Applications," key insights are provided on enhancing the efficiency and durability of ceramic cylinders. Understanding the intrinsic material properties is essential for optimal performance, paired with critical design considerations tailored to specific industrial settings. Effective maintenance practices play a pivotal role in prolonging the lifespan of ceramic cylinders, while selecting the right manufacturing techniques ensures high-quality production. Additionally, optimizing thermal and mechanical load conditions can greatly impact efficiency, and innovative coating solutions offer further enhancements to performance.

At ST.CERA CO., LTD., we leverage our expertise in precision ceramic manufacturing to deliver superior ceramic cylinders. Our team of specialists focuses on cutting-edge research and development, ensuring that our products meet the rigorous demands of various industrial applications while maximizing performance and longevity.

Related Posts

-

The Ultimate Guide to Optimizing Your Semiconductor Spare Parts Inventory Management

-

Unlocking Precision: The Benefits of Using Ceramic Chucks in Manufacturing Processes

-

5 Reasons Why the Best 4 Inch Ceramic End Effector is a Game Changer

-

Unmatched Quality: Discover the Excellence of China's Premier Zirconia Ceramic Pin Manufacturer

-

The Ultimate Guide to Zirconia Ceramic Rods: Unveiling Key Properties and Market Trends

-

Innovative Ceramic Bush Applications in Modern Engineering Solutions

Blog Tags: