How to Maximize Performance with a Ceramic Capture Ring in Your Processes

Table of Contents

- Understanding the Functionality of Ceramic Capture Rings in Industrial Applications

- Key Benefits of Integrating Ceramic Capture Rings into Your Workflow

- Best Practices for Installing and Maintaining Ceramic Capture Rings

- Optimizing Process Efficiency: Measuring Performance Improvements with Ceramic Rings

- Troubleshooting Common Issues with Ceramic Capture Rings in Operations

- FAQS

- Conclusion

- Related Posts

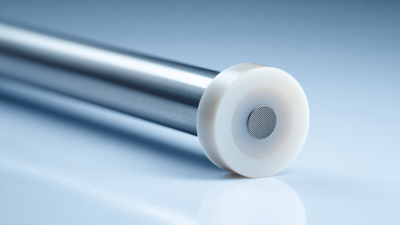

In today's fast-paced technological landscape, maximizing performance in various processes is crucial for maintaining a competitive edge. One innovative solution that has emerged is the Ceramic Capture Ring, a precision component that significantly enhances operational efficiency and reliability. At ST.CERA CO., LTD., a leading high-tech enterprise specializing in precision ceramic manufacturing, we understand the importance of delivering top-quality parts that can withstand demanding conditions. Our team of experts is dedicated to advancing the capabilities of Ceramic Capture Rings through rigorous research and development, ensuring they meet the highest standards of performance in diverse applications. This article explores effective strategies for incorporating Ceramic Capture Rings into your processes, highlighting how they can optimize functionality and drive success across various industries.

Understanding the Functionality of Ceramic Capture Rings in Industrial Applications

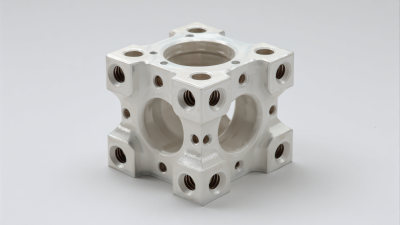

Ceramic capture rings play a critical role in enhancing industrial processes by providing superior mechanical properties and thermal stability. These rings function primarily by capturing and containing specific particles or emissions during industrial operations, thereby minimizing contamination and improving process efficiency. Their high resistance to wear and corrosive environments makes them ideal for use in applications such as chemical processing, mineral extraction, and pollution control. By effectively managing the flow of materials, ceramic capture rings contribute to a safer and more sustainable working environment.

Additionally, the functionality of ceramic capture rings extends beyond mere containment. Their design enables a seamless integration into existing systems, ensuring minimal disruption to ongoing operations. The ability to withstand elevated temperatures and aggressive media allows for prolonged performance, reducing maintenance costs and downtime. Industry professionals can leverage these benefits by incorporating ceramic capture rings into their processes to attain optimal performance levels. Ultimately, understanding the effectiveness of these components is essential for any organization aiming to enhance operational efficiency and comply with environmental regulations.

How to Maximize Performance with a Ceramic Capture Ring in Your Processes

| Application Area | Capture Ring Material | Temperature Resistance (°C) | Chemical Compatibility | Performance Increase (%) |

|---|---|---|---|---|

| Oil & Gas | Zirconia | 1200 | Highly resistant to hydrocarbons | 30 |

| Food Processing | Alumina | 800 | Acid and alkali resistant | 25 |

| Aerospace | Silicon Nitride | 1500 | Excellent oxidation resistance | 40 |

| Automotive | Boron Nitride | 1200 | Oil and fuel resistant | 35 |

Key Benefits of Integrating Ceramic Capture Rings into Your Workflow

Integrating ceramic capture rings into industrial processes offers numerous key benefits that can significantly enhance operational efficiency. According to a recent report by the Ceramic Manufacturing Association, companies that adopt ceramic components in their workflows experience up to a 30% increase in process reliability. This improvement is largely due to the superior wear resistance and thermal stability of ceramic materials, which reduce downtime and maintenance costs associated with traditional materials.

Furthermore, ceramic capture rings are known for their ability to handle extreme conditions, including high temperatures and corrosive environments. A study from the International Materials Research Society indicates that equipment using ceramic capture rings can withstand operational stresses up to 200% longer than those using metal alternatives. This longevity translates to lower replacement rates and improved performance consistency, allowing businesses to maintain higher production levels and meet market demands effectively. By incorporating these advanced materials, organizations not only streamline their processes but also align with sustainability goals, as ceramics are often more environmentally friendly compared to their metal counterparts.

Best Practices for Installing and Maintaining Ceramic Capture Rings

When installing a ceramic capture ring, proper preparation and technique are crucial to ensure optimal performance. Start by selecting the right size and material of the ceramic ring that matches your specific process requirements. Before installation, it's important to clean the installation surface thoroughly to remove any contaminants that might interfere with the sealing capabilities of the ring. Utilize appropriate tools to securely fit the ceramic ring, ensuring that it is aligned perfectly to avoid any misalignments that could lead to performance inefficiencies.

Maintaining the integrity of the ceramic capture ring is equally vital for its long-term functionality. Regular inspections should be part of the maintenance routine to identify any signs of wear or damage. Ensure that the environment in which the ring operates is controlled, limiting exposure to harsh chemicals or extreme temperatures that could compromise its performance. Implementing a cleaning schedule that respects the material properties of the ceramic can prevent buildup and enhance its lifespan. By adhering to these best practices, you can maximize the effectiveness of ceramic capture rings in your processes, leading to improved productivity and reduced downtime.

Optimizing Process Efficiency: Measuring Performance Improvements with Ceramic Rings

Ceramic capture rings are increasingly recognized for their ability to enhance process efficiency in various industrial applications. By integrating these advanced materials, organizations can significantly improve performance metrics such as yield, energy consumption, and overall throughput. The inherent properties of ceramics, including high resistance to wear and thermal stability, allow capture rings to withstand harsh conditions while maintaining structural integrity. As a result, processes equipped with ceramic capture rings often exhibit lower maintenance demands and reduced downtime, leading to enhanced productivity.

To effectively measure the performance improvements attributed to ceramic rings, it is essential to establish baseline data before implementation. Key performance indicators (KPIs) such as cycle time, defect rates, and resource utilization should be closely monitored. By conducting comparative analyses post-implementation, businesses can quantify the gains achieved, attributing them directly to the use of ceramic materials. These metrics not only help in justifying the investment in ceramic capture rings but also offer valuable insights for continuous improvement strategies in process optimization.

Troubleshooting Common Issues with Ceramic Capture Rings in Operations

When utilizing ceramic capture rings in various operations, technicians may encounter several common issues that can impede performance. One prevalent challenge is the buildup of debris or particulate matter within the ring, which can alter its intended functionality. Regular maintenance and cleaning schedules should be implemented to prevent this buildup. Operators should be trained to recognize signs of obstruction and take swift action to mitigate any negative impacts on efficiency.

Another common issue involves improper installation or alignment of the ceramic capture rings. Incorrect positioning can lead to uneven wear, affecting both the ring’s effectiveness and the overall performance of the system. To minimize misalignment, it is crucial to follow the manufacturer's guidelines closely during the installation process. Additionally, regular inspections can help identify wear patterns early, allowing for timely adjustments and prolonging the lifespan of the capture rings in operations. By actively addressing these common issues, teams can significantly enhance the reliability and efficiency of their processes.

Maximizing Performance with Ceramic Capture Rings

This chart illustrates the performance metrics of ceramic capture rings under various operational scenarios, focusing on efficiency, durability, and common issues experienced in processes.

FAQS

: Ceramic capture rings are used to capture and contain specific particles or emissions during industrial operations, reducing contamination and improving process efficiency.

Ceramic capture rings provide superior mechanical properties and thermal stability, making them resistant to wear and suitable for corrosive environments.

Regular maintenance is essential to prevent the buildup of debris or particulate matter within the rings, which can alter their functionality and efficiency.

Common issues include debris buildup within the rings and improper installation or alignment, both of which can lead to reduced performance and efficiency.

Technicians can implement regular cleaning schedules and train operators to identify signs of obstruction to mitigate the impacts of debris buildup.

Following manufacturer guidelines is crucial to ensure proper installation and alignment of ceramic capture rings, which helps avoid uneven wear and maintains system performance.

The design of ceramic capture rings allows for seamless integration into existing systems and the ability to withstand elevated temperatures and aggressive media, enhancing overall performance.

By effectively managing emissions and minimizing contamination, ceramic capture rings help organizations comply with environmental regulations and contribute to a safer working environment.

Regular inspections can help identify wear patterns early, allowing for timely adjustments that prolong the lifespan and reliability of the ceramic capture rings.

Conclusion

The article "How to Maximize Performance with a Ceramic Capture Ring in Your Processes" delves into the essential role that Ceramic Capture Rings play in enhancing industrial operations. It begins by explaining their functionality in various applications, highlighting how these components can significantly improve workflow efficiency. The benefits of integrating Ceramic Capture Rings are outlined, showcasing their ability to reduce wear, increase precision, and minimize downtime.

Best practices for installation and maintenance are discussed to ensure optimal performance, alongside methods for measuring efficiency improvements directly attributed to these ceramic components. Additionally, the article addresses common troubleshooting issues that may arise during operations. With expertise in precision ceramic manufacturing, St.Cera Co., Ltd. is well-positioned to provide high-quality Ceramic Capture Rings that drive operational excellence in diverse industrial settings.

Related Posts

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

7 Best Ceramic Lift Pins for Enhanced Performance in Manufacturing

-

Innovative Ceramic Bush Applications in Modern Engineering Solutions

-

Innovative Applications of Aluminum Nitride Plates in Modern Technology

-

What You Need to Know About 4'' Ceramic End Effectors: A Comprehensive Guide

-

5 Reasons Why the Best 4 Inch Ceramic End Effector is a Game Changer

Blog Tags: