Innovative Use Cases for Silicon Nitride Ceramic Sleeve in Modern Applications

Table of Contents

- Understanding Silicon Nitride Ceramics: Properties and Benefits

- Key Industrial Applications of Silicon Nitride Ceramic Sleeves

- Innovative Design Approaches for Silicon Nitride in Manufacturing

- Challenges and Solutions in Implementing Silicon Nitride Sleeves

- Future Trends in Silicon Nitride Ceramic Technology and Applications

- FAQS

- Related Posts

In recent years, the demand for advanced materials in various high-tech industries has surged, with the silicon nitride ceramic sleeve emerging as a pivotal component across diverse applications. According to a recent market report, the global ceramic materials market is projected to grow at a CAGR of 8.5% through 2025, propelled by the increasing need for lightweight, durable, and high-performance materials. St.Cera Co., Ltd., a leading player in precision ceramic manufacturing, is at the forefront of this innovation, leveraging a team of top-ranking experts to explore the myriad benefits of silicon nitride ceramic sleeves. These sleeves are recognized for their exceptional mechanical strength, thermal stability, and resistance to wear, making them ideal for automotive, aerospace, and electronics applications.

This ultimate guide will delve into innovative use cases for silicon nitride ceramic sleeves, highlighting their transformative potential in modern technology.

Understanding Silicon Nitride Ceramics: Properties and Benefits

Silicon nitride (Si3N4) ceramics have garnered significant attention in various modern applications due to their remarkable physical and mechanical properties. Characteristically, these ceramics exhibit exceptional hardness, thermal stability, and resistance to wear, making them suitable for high-performance environments such as aerospace and biomedical fields. Recent studies highlight their potential in all-ceramic dental restorations, showcasing not just their durability but also advantageous properties like biocompatibility and customizable color shades.

The advancements in fabrication techniques, including digital light processing and centripetal sinter-forging, have further enhanced the mechanical performance of silicon nitride ceramics. These methods enable the creation of textured ceramics with superior flexural strength and reliability, paving the way for their application in specialized areas, such as dental implants. Notably, the innovative use of machine learning to study the mechanical properties of beta silicon nitride expands our understanding and opens new avenues for future applications, reinforcing the position of silicon nitride ceramics as a leading material in modern technology.

Key Industrial Applications of Silicon Nitride Ceramic Sleeves

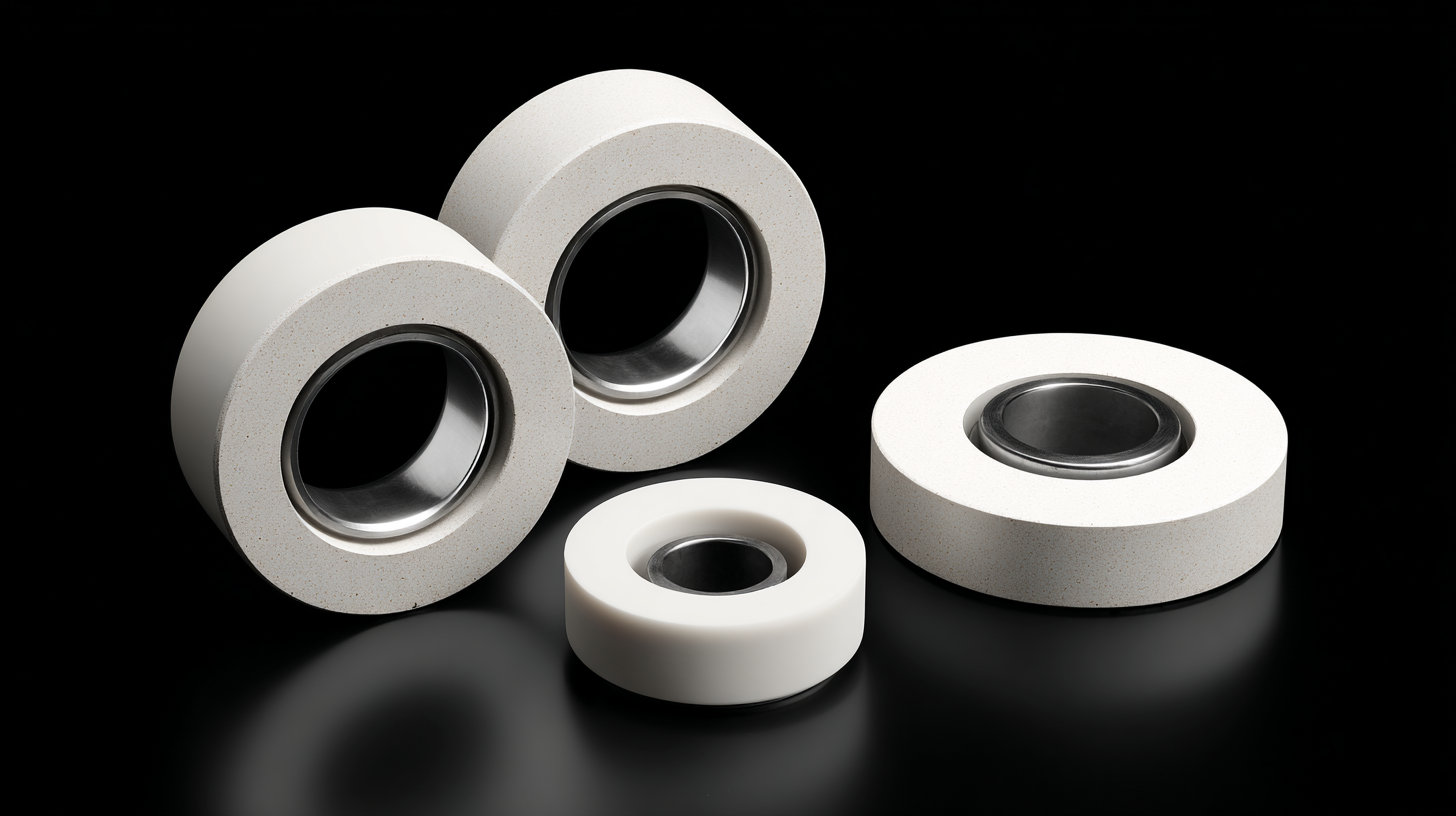

Silicon nitride ceramic sleeves are increasingly recognized for their versatility in various industrial applications. These advanced materials offer exceptional thermal and mechanical properties, making them ideal for high-stress environments. In semiconductor packaging, for instance, silicon nitride sleeves play a crucial role by providing enhanced thermal insulation and electrical isolation.

This not only improves the efficiency of devices but also contributes to longer lifespans, a significant advantage as electronic components become more compact and powerful.

Silicon nitride ceramic sleeves are increasingly recognized for their versatility in various industrial applications. These advanced materials offer exceptional thermal and mechanical properties, making them ideal for high-stress environments. In semiconductor packaging, for instance, silicon nitride sleeves play a crucial role by providing enhanced thermal insulation and electrical isolation.

This not only improves the efficiency of devices but also contributes to longer lifespans, a significant advantage as electronic components become more compact and powerful.

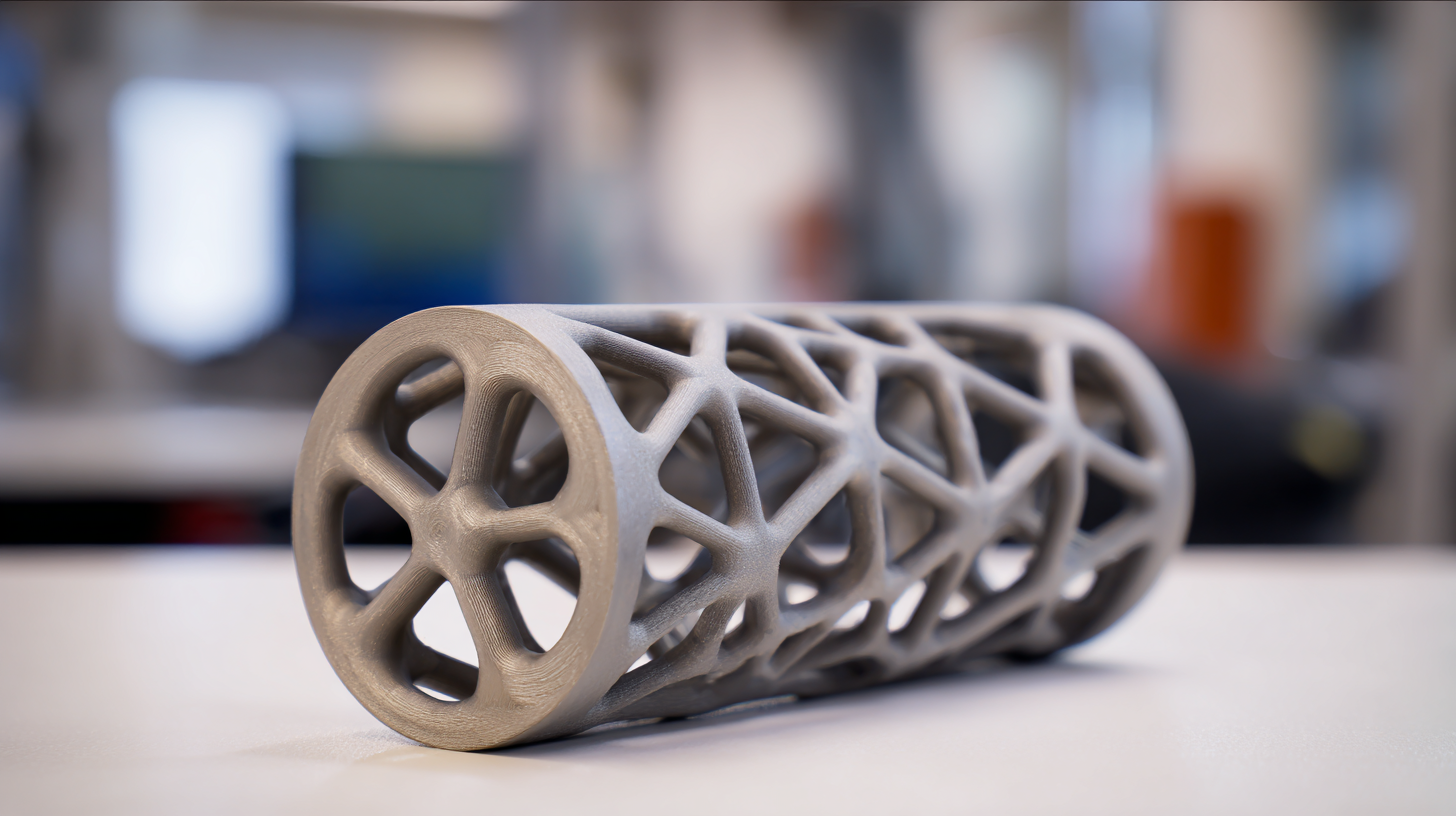

Another promising application is in the field of additive manufacturing, where silicon nitride serves as a vital component in producing ceramic parts with intricate geometries. Its ability to withstand high temperatures and corrosive environments makes it suitable for industries such as aerospace and automotive, where precision and durability are paramount. As the demand for advanced ceramics continues to grow, the innovations surrounding silicon nitride sleeves will likely reshape how manufacturers approach design and functionality, ultimately driving forward the capabilities of modern technologies.

Innovative Design Approaches for Silicon Nitride in Manufacturing

Silicon nitride has emerged as a transformative material in modern manufacturing, particularly owing to its exceptional thermal stability and mechanical properties. In a recent report by MarketsandMarkets, the global silicon nitride market is expected to reach $1.9 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth is largely driven by innovative design approaches that leverage the material’s unique characteristics, such as high strength-to-weight ratio and resistance to oxidation, which allow engineers to design more efficient and durable components.

Adopting advanced design methods, including topology optimization and the integration of computer-aided design (CAD) tools, manufacturers are pushing the boundaries of what silicon nitride can achieve. For instance, companies are exploring the use of silicon nitride ceramic sleeves in high-performance applications, such as turbine engines and aerospace components, where reducing weight while maintaining strength is crucial. According to a report by Research and Markets, the aerospace segment alone is anticipated to account for over 25% of the silicon nitride applications by 2025, highlighting the material’s potential to revolutionize manufacturing processes across various industries.

Innovative Use Cases for Silicon Nitride Ceramic Sleeve in Modern Applications

| Application Area | Innovative Design Approach | Benefits | Material Properties |

|---|---|---|---|

| Aerospace Engineering | Lightweight Structures | Reduced Fuel Consumption | High Temp Resistance |

| Medical Devices | Biocompatible Coatings | Improved Patient Safety | Chemical Stability |

| Oil & Gas Industry | High-Performance Drill Bits | Extended Service Life | Wear Resistance |

| Electronics | High-Frequency Components | Enhanced Signal Integrity | Low Dielectric Loss |

| Automotive Industry | Engine Components | Improved Efficiency | Thermal Shock Resistance |

Challenges and Solutions in Implementing Silicon Nitride Sleeves

Silicon nitride ceramic sleeves are making waves in various modern applications due to their outstanding mechanical properties and biocompatibility. However, the implementation of these materials presents several challenges that need addressing. One significant concern is the manufacturing precision and scalability of silicon nitride components. As highlighted in industry reports, achieving consistent quality at scale can be difficult, often necessitating advanced techniques such as additive manufacturing. This technology not only enhances production efficiency but also allows for the creation of complex geometries that traditional methods struggle to achieve.

Moreover, the integration of silicon nitride sleeves into biomedical applications must overcome biocompatibility issues. While silicone biomaterials have dominated the market due to their favorable properties, silicon nitride's antimicrobial characteristics present a compelling case for its use in implantable devices. Research indicates that silicon nitride can significantly reduce infection risks associated with implants, which is critical in procedures such as renal cell therapy. As reported, the feasibility of implantable systems using silicon-based materials is increasingly promising, paving the way for innovative treatments. Adequate solutions and continued research into the interplay of material properties will be essential as we navigate the challenges of introducing silicon nitride sleeves in modern applications.

Future Trends in Silicon Nitride Ceramic Technology and Applications

The advancement of silicon nitride ceramic technology is poised to revolutionize various modern applications, particularly in industries such as aerospace, automotive, and electronics. According to a recent report by Markets and Markets, the global silicon nitride ceramics market is projected to grow from $1.2 billion in 2021 to $1.8 billion by 2026, at a CAGR of 8.5%. This growth is driven by the material's exceptional properties, including high thermal stability, low density, and excellent wear resistance, making it ideal for high-performance applications.

Innovative use cases for silicon nitride include its application in cutting tools, which can outperform traditional tools by offering longer life and better precision. Data from Grand View Research suggests that the demand for advanced ceramics in the manufacturing sector will escalate, with a compound annual growth rate of 6.7% anticipated through 2027. Furthermore, the utilization of silicon nitride in biomedical implants is gaining traction due to its biocompatibility and strength, supporting the push towards more durable and effective medical solutions. As the industry continues to evolve, we can expect an increase in the integration of silicon nitride ceramics in high-tech sectors, marking a significant shift in material science and engineering capabilities.

Innovative Use Cases for Silicon Nitride Ceramic Sleeve

This chart displays the innovative applications of Silicon Nitride ceramics across various industries, highlighting key use cases and their corresponding growth trends.

FAQS

: Silicon nitride ceramic sleeves are used for thermal insulation and electrical isolation in semiconductor packaging, enhancing device efficiency and lifespan.

They enable the production of intricate ceramic parts in additive manufacturing and are suitable for high temperatures and corrosive environments, particularly in aerospace and automotive sectors.

The growth is largely driven by innovative design approaches that utilize the material's high strength-to-weight ratio and oxidation resistance, expected to reach $1.9 billion by 2026.

Manufacturers are using topology optimization and computer-aided design (CAD) tools to develop more efficient and durable components.

The aerospace sector is anticipated to account for over 25% of silicon nitride applications by 2025, alongside automotive and electronics industries.

The global silicon nitride ceramics market is projected to grow at a CAGR of 8.5%, from $1.2 billion in 2021 to $1.8 billion by 2026.

Silicon nitride is used in cutting tools for superior longevity and precision and is gaining traction in biomedical implants due to its biocompatibility and strength.

They provide high thermal stability, low density, and excellent wear resistance, making them ideal for demanding environments.

The demand for advanced ceramics in manufacturing is anticipated to grow with a compound annual growth rate of 6.7% through 2027.

There will likely be increased integration of silicon nitride ceramics in high-tech sectors, marking significant advancements in material science and engineering capabilities.

Related Posts

-

Ultimate Guide to Sourcing the Best Ceramic C-Shape Rings for Global Markets

-

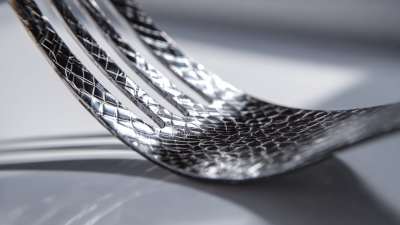

2025 Trends in Advanced Ceramics: Innovative Solutions for Best Sic Ceramic Fork Applications

-

How to Choose the Best Sapphire Tube: Essential Metrics and Industry Insights for Global Buyers

-

How to Choose the Best Silicon Carbide Plates for Your Industrial Needs

-

Navigating Global Trade Certifications for Best Al2o3 Ceramic Rod Purchases

-

Choosing the Right Manufacturer for the Best Ceramic Guide Pin: Essential Solutions and Tips

Blog Tags: