Innovative Ceramic Bush Applications in Modern Engineering Solutions

Table of Contents

- Emerging Trends in Ceramic Bush Alternatives for Engineering Applications

- Advantages of Ceramic Bushes Over Traditional Materials in Engineering

- Applications of Innovative Ceramic Bush Solutions in Various Industries

- Exploring the Environmental Benefits of Ceramic Bush Alternatives

- Future Prospects: Advancements in Ceramic Bush Technologies for Engineering

- FAQS

- Conclusion

- Related Posts

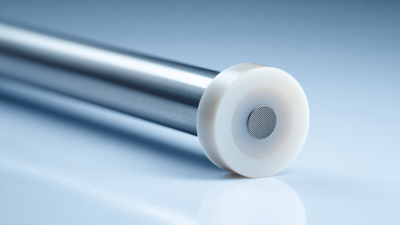

In the rapidly advancing field of modern engineering, the demand for innovative materials has never been greater. Among these, the Ceramic Bush has emerged as a pivotal component, especially in applications requiring high precision and durability. According to a recent report by Markets and Markets, the global ceramics market is expected to reach $341 billion by 2025, with advanced ceramic applications driving a significant portion of this growth.

ST.CERA CO., LTD. stands at the forefront of this evolution, specializing in precision ceramic manufacturing. With a robust team of experts dedicated to research and development, ST.CERA focuses on delivering high-quality ceramic parts that meet the stringent demands of various engineering applications. The integration of Ceramic Bushes into mechanical assemblies not only enhances performance but also contributes to longer operational lifespans and reduced maintenance costs, making them essential for engineers seeking reliable solutions.

Emerging Trends in Ceramic Bush Alternatives for Engineering Applications

In recent years, the engineering sector has witnessed a notable shift towards innovative materials, particularly in the realm of ceramic bush alternatives. As manufacturers strive for efficiency and performance, ceramics have emerged as an attractive solution due to their superior wear resistance and lightweight properties. These materials are finding applications in various fields, from automotive components to aerospace systems, where reliability and durability are paramount.

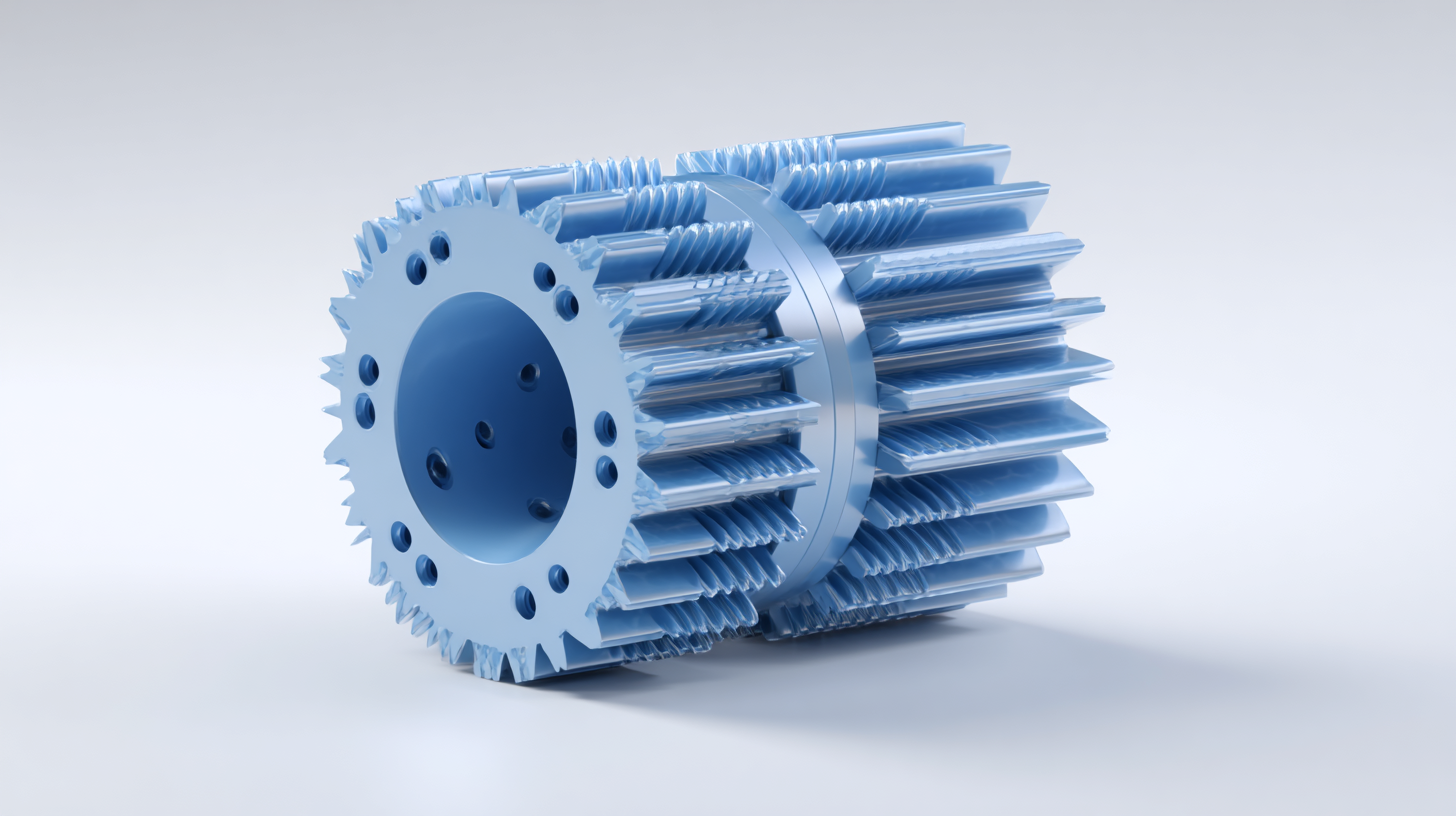

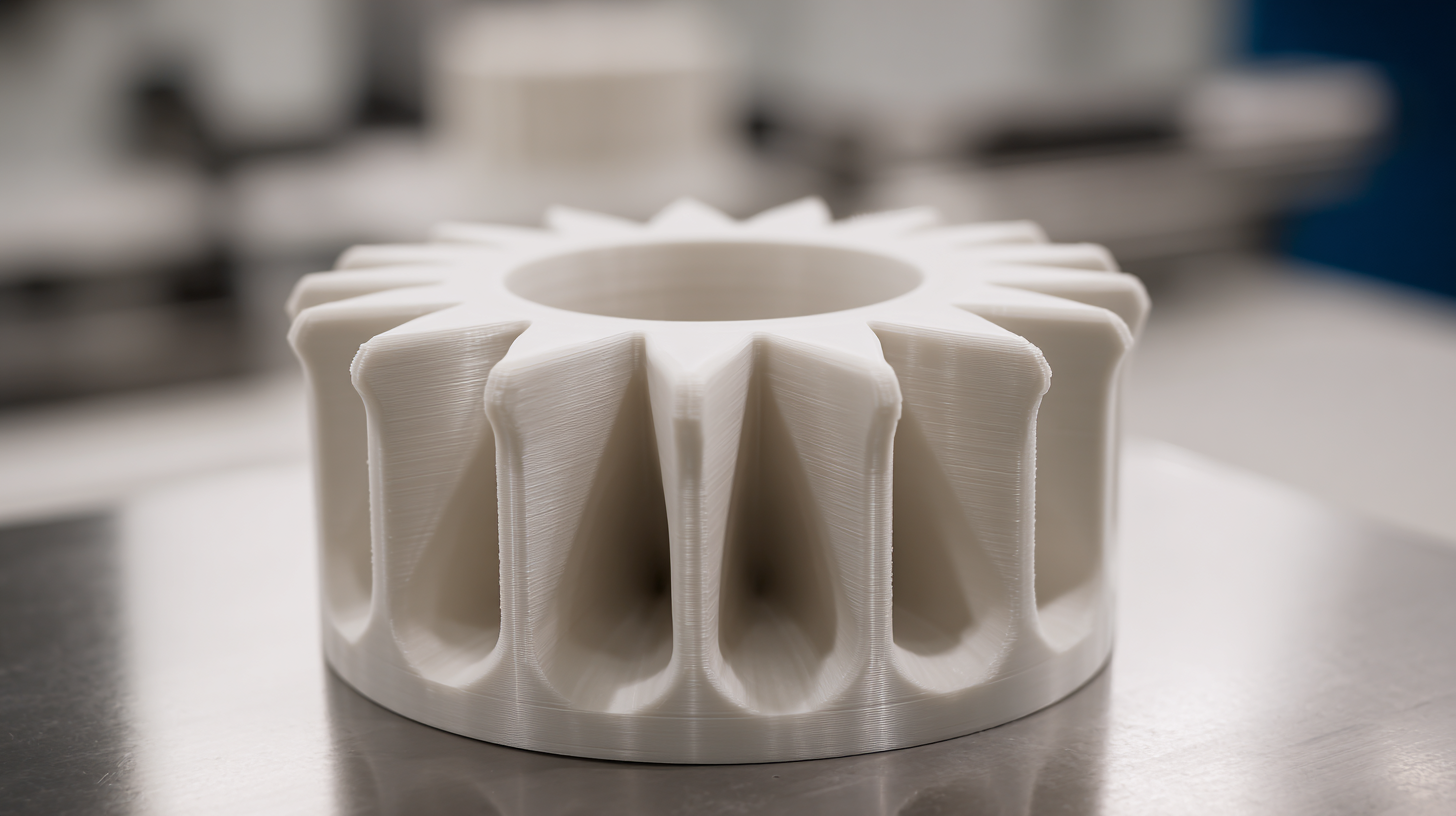

Emerging trends indicate a growing interest in hybrid ceramic formulations that combine traditional ceramics with advanced composites. This integration enhances mechanical performance while providing cost-effective solutions for manufacturers. Additionally, advancements in 3D printing technology are enabling the rapid prototyping of ceramic bushes, allowing engineers to customize designs and reduce lead times. As industries continue to evolve, the exploration of alternative materials will undoubtedly shape the future landscape of engineering applications, paving the way for even more innovative solutions.

Innovative Ceramic Bush Applications in Modern Engineering Solutions

| Application Area | Material Type | Advantages | Emerging Trends |

|---|---|---|---|

| Automotive Component Manufacturing | Alumina Ceramics | High wear resistance and low friction | Increased use of lightweight materials |

| Aerospace Engineering | Silicon Nitride | High thermal stability | 3D printing techniques for custom shapes |

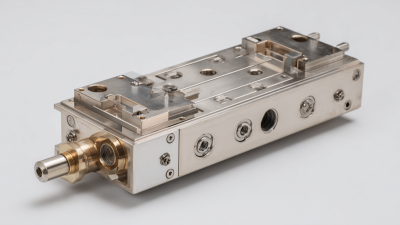

| Industrial Machinery | Zirconia Ceramics | Corrosion resistance | Integration with smart monitoring systems |

| Medical Devices | Biocompatible Ceramics | Non-reactive and safe for body use | Customization via additive manufacturing |

| Energy Sector | Porous Ceramics | Lightweight and thermal insulators | Innovative designs for heat exchangers |

Advantages of Ceramic Bushes Over Traditional Materials in Engineering

Ceramic bushes are quickly gaining traction in modern engineering due to their superior performance compared to traditional materials like metal and plastic. One of the primary advantages of ceramic bushes is their exceptional wear resistance. According to a report by the International Journal of Applied Ceramic Technology, ceramics can exhibit wear rates up to 40% lower than that of conventional materials, ultimately leading to longer service life for components. This durability makes ceramic bushes an ideal choice for high-stress applications, such as in automotive and aerospace engineering.

In addition to wear resistance, ceramic bushes are notably lightweight, enhancing efficiency in various engineering solutions. A study published by the Materials Research Society indicated that using ceramic components can reduce overall system weight by up to 30%, which is particularly beneficial in reducing energy consumption in vehicles. Additionally, ceramic materials have excellent thermal stability, allowing them to perform in extreme temperature conditions without losing structural integrity.

**Tip: When selecting materials for engineering applications, consider the specific operational environment to maximize performance and longevity.** It's essential to assess the temperature, pressure, and chemical exposure when choosing between ceramic and traditional materials.

**Tip: Implement regular maintenance checks to ensure that your ceramic bushes are functioning optimally, which can further enhance their lifespan and performance.** Integrating ceramic bushes into your engineering design can yield substantial long-term benefits, elevating the efficiency of your systems.

Applications of Innovative Ceramic Bush Solutions in Various Industries

Innovative ceramic bush solutions are making significant strides across various industries, showcasing their versatility and performance-enhancing attributes. These advanced ceramics are increasingly utilized in applications ranging from automotive components to medical devices, where their lightweight and durable properties offer substantial benefits. For instance, the integration of ceramic bushes in automotive systems helps reduce weight and improve fuel efficiency while maintaining strength and wear resistance, crucial for high-performance vehicles.

Innovative ceramic bush solutions are making significant strides across various industries, showcasing their versatility and performance-enhancing attributes. These advanced ceramics are increasingly utilized in applications ranging from automotive components to medical devices, where their lightweight and durable properties offer substantial benefits. For instance, the integration of ceramic bushes in automotive systems helps reduce weight and improve fuel efficiency while maintaining strength and wear resistance, crucial for high-performance vehicles.

In the medical field, ceramic bush applications are transforming equipment reliability and performance. The inherent antibacterial properties of innovative ceramic materials are being harnessed to create safer medical devices, reducing infection risks in critical healthcare settings. Furthermore, the growing demand for advanced separation technologies has spurred the development of ceramic membranes, which are acclaimed for their exceptional chemical and thermal stability, facilitating industrial processes in sectors like water treatment and energy. As these applications continue to evolve, the future of ceramic bush technology promises to unlock new possibilities and solutions in modern engineering.

Exploring the Environmental Benefits of Ceramic Bush Alternatives

As industries seek innovative engineering solutions, ceramic bushings have emerged as a sustainable alternative to traditional materials like metal and plastic. The environmental benefits of ceramic bush alternatives are significant; studies show that ceramics can reduce energy consumption by up to 40% in manufacturing processes. Additionally, the longevity and durability of ceramic components lead to less frequent replacements, thereby minimizing waste and lowering overall carbon footprints.

At ST.CERA CO., LTD., we pride ourselves on being at the forefront of precision ceramic manufacturing. Our advanced research and development initiatives have enabled us to produce high-quality ceramic bushings that are not only efficient but also environmentally friendly. Our expert team focuses on developing materials that can resist wear and corrosion, which ensures a longer life cycle and further contributes to sustainability within various industries.

Tips for integrating ceramic bushings into your projects include evaluating specific application requirements, considering the potential cost savings from reduced maintenance, and collaborating with experienced manufacturers like ST.CERA to tailor solutions that meet your needs. Emphasizing the lifecycle analysis of materials can also guide decision-making towards more eco-friendly practices, supporting both environmental goals and operational efficiency.

Innovative Ceramic Bush Applications in Modern Engineering Solutions

This chart illustrates the environmental benefits of using ceramic bush alternatives in engineering applications compared to traditional materials over the past five years. The data showcases a significant reduction in carbon emissions, waste production, and energy consumption associated with ceramic bushes.

Future Prospects: Advancements in Ceramic Bush Technologies for Engineering

The advancements in ceramic bush technologies are revolutionizing modern engineering solutions, providing innovative approaches to traditional challenges. The unique properties of ceramics, such as their high wear resistance, lightweight nature, and thermal stability, make them ideal for a variety of applications. As industries move towards more sustainable and efficient practices, ceramic bushes are emerging as a reliable alternative to metal components, reducing overall environmental impact and operational costs. Future prospects for ceramic bush technologies are promising, as ongoing research focuses on enhancing their performance and versatility. Innovations in material science, such as the development of composite ceramics, are paving the way for stronger and more durable solutions that can withstand extreme conditions. Additionally, advancements in manufacturing processes, including 3D printing, open up new possibilities for custom designs and applications in specific engineering fields. As these technologies continue to evolve, ceramic bushes are expected to play a crucial role in the future landscape of engineering, offering solutions that align with the push towards smarter, more efficient systems.

Future prospects for ceramic bush technologies are promising, as ongoing research focuses on enhancing their performance and versatility. Innovations in material science, such as the development of composite ceramics, are paving the way for stronger and more durable solutions that can withstand extreme conditions. Additionally, advancements in manufacturing processes, including 3D printing, open up new possibilities for custom designs and applications in specific engineering fields. As these technologies continue to evolve, ceramic bushes are expected to play a crucial role in the future landscape of engineering, offering solutions that align with the push towards smarter, more efficient systems.

FAQS

: Ceramic bushes offer superior wear resistance, being able to exhibit wear rates up to 40% lower than conventional materials. They are also lightweight, provide excellent thermal stability, and ensure longer service life in high-stress applications.

Ceramic bushes are used across various industries, including automotive, aerospace, and medical applications, due to their durability and lightweight properties that enhance performance and efficiency.

The lightweight nature of ceramic components can reduce overall vehicle weight by up to 30%, which helps improve fuel efficiency and reduce energy consumption.

Ceramic bushes have inherent antibacterial properties, making them ideal for creating safer medical devices that reduce infection risks in healthcare settings.

Ceramic bush technologies promise to enhance performance and versatility, with ongoing research focusing on developing composite ceramics and utilizing advanced manufacturing processes like 3D printing for custom designs.

It is essential to assess the specific operational environment, including temperature, pressure, and chemical exposure, to maximize the performance and longevity of materials, whether ceramic or traditional.

Implementing regular maintenance checks is advised to ensure that ceramic bushes are functioning optimally, which can further enhance their lifespan and performance.

As industries shift towards more sustainable practices, ceramic bushes present a reliable alternative to metal components, thereby reducing environmental impact and operational costs.

The high wear resistance, lightweight nature, and thermal stability of ceramic bushes make them ideal for high-performance automotive applications, enhancing strength and wear resistance.

Ceramic membranes are acclaimed for their exceptional chemical and thermal stability, making them valuable in advanced separation technologies, particularly in water treatment and energy sectors.

Conclusion

In the modern engineering landscape, the demand for innovative materials has led to the rise of Ceramic Bush applications. Emerging trends highlight the advantages these ceramic solutions offer over traditional materials, including enhanced durability, reduced friction, and weight savings. Industries ranging from automotive to aerospace are increasingly adopting ceramic bushes, which not only improve performance but also contribute to sustainability by being more environmentally friendly alternatives.

As a leader in precision ceramic manufacturing, St.Cera Co., Ltd. is at the forefront of this exciting transition. Our commitment to research and development enables us to provide cutting-edge ceramic bush technologies, paving the way for future advancements in engineering. As the industry evolves, the role of Ceramic Bush solutions will continue to grow, representing a pivotal shift towards more innovative and sustainable engineering practices.

Related Posts

-

Innovative Use Cases for Silicon Nitride Ceramic Sleeve in Modern Applications

-

How to Choose the Best Sapphire Tube: Essential Metrics and Industry Insights for Global Buyers

-

Top Global Manufacturers of Best Bernoulli Wafer Arm for International Buyers

-

Ultimate Guide to Sourcing the Best Sic Wafer Arm for Your Manufacturing Needs

-

7 Essential Tips for Sourcing the Best Silicon Carbide Bushing Globally

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

Blog Tags: