Innovative Applications of Aluminum Nitride Plates in Modern Technology

Table of Contents

- Revolutionizing Thermal Management in Electronics with Aluminum Nitride Plates

- Enhancing Power Electronics: The Role of Aluminum Nitride in Energy Efficiency

- Advancements in LED Technology: How Aluminum Nitride Plates Improve Performance

- Exploring the Use of Aluminum Nitride in High-Temperature Applications

- Innovative Fabrication Techniques for Aluminum Nitride Plates in Modern Devices

- Aluminum Nitride vs. Traditional Materials: A Comparative Analysis of Benefits

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving landscape of modern technology, Aluminum Nitride Plates have emerged as a pivotal material, revolutionizing various industries due to their exceptional thermal conductivity, electrical insulation, and mechanical strength. According to market research by Mordor Intelligence, the global aluminum nitride market is projected to grow at a CAGR of 13.2% from 2021 to 2026, underscoring the rising demand for advanced ceramics in sectors such as electronics, aerospace, and energy. At ST.CERA CO., LTD., our commitment to precision ceramic manufacturing allows us to leverage these innovative properties of Aluminum Nitride Plates, providing cutting-edge solutions that meet the rigorous demands of modern applications. With a dedicated team of experts, we specialize in research and development, ensuring that our products consistently align with industry advancements and customer needs.

Revolutionizing Thermal Management in Electronics with Aluminum Nitride Plates

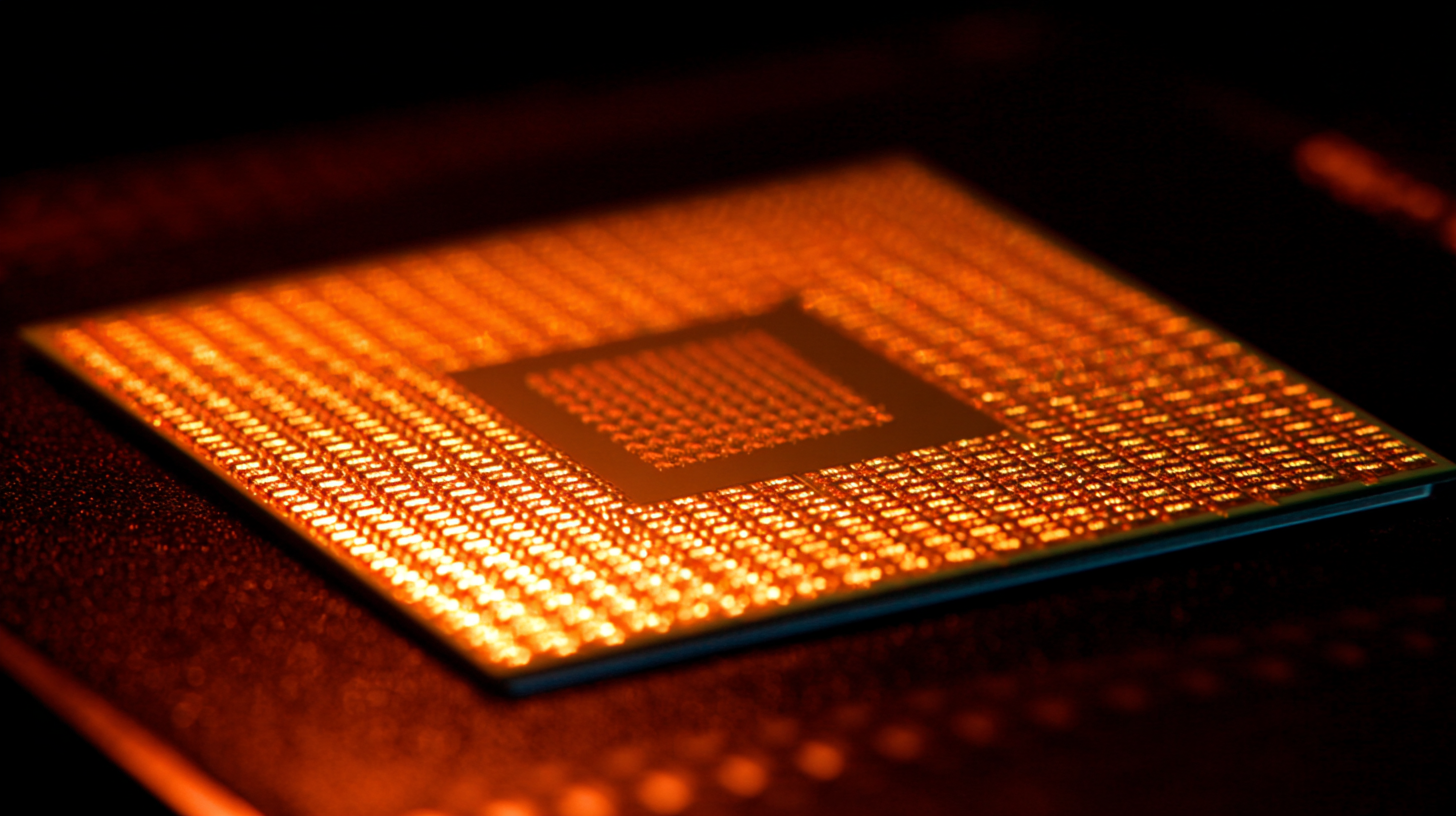

In the realm of modern electronics, the need for effective thermal management has never been more critical. As devices become increasingly compact and powerful, the ability to dissipate heat efficiently has become a key factor influencing performance and longevity. Aluminum nitride (AlN) plates are emerging as a game-changer in this domain, offering superior thermal conductivity combined with excellent electrical insulation properties. This unique combination makes AlN an ideal material for applications in high-performance electronics, including semiconductors and LED technology.

The innovative applications of aluminum nitride plates extend beyond basic heat dissipation. They are being integrated into next-generation devices where thermal stability is paramount, allowing for faster operation and improved reliability. The lightweight and durable nature of AlN plates also contributes to their appeal, enabling designers to create more efficient and sleek electronic components.

As industries continue to push the boundaries of technology, the role of aluminum nitride in thermal management serves as a shining example of how advanced materials can revolutionize electronic design and performance, paving the way for sophisticated, high-functionality devices that meet the demands of a fast-paced technological landscape.

Enhancing Power Electronics: The Role of Aluminum Nitride in Energy Efficiency

Aluminum nitride (AlN) has emerged as a pivotal material in enhancing energy efficiency in power electronics. Thanks to its high thermal conductivity and stability, AlN serves as an ideal substrate for high-power circuits, minimizing heat dissipation and improving overall performance. As the global demand for more efficient energy solutions escalates, the wide bandgap semiconductor market is anticipated to reach USD 8.42 billion by 2034, reflecting a growing shift towards materials that can operate under high-voltage and high-temperature conditions.

Recent innovations, including a heating-assisted laser direct writing technique for creating low-resistance conductive layers on AlN ceramics, demonstrate the exciting possibilities in this field. These advancements not only enhance the efficiency of power converters but also contribute to the adoption of aluminum gallium nitride (AlGaN) in high-performance applications. With projections estimating the aluminum nitride market to soar to $245.8 million by 2033, it is clear that AlN will play an integral role in the future of energy-efficient technologies, particularly as researchers continue to explore substrate engineering pathways to elevate the capabilities of power electronics.

Advancements in LED Technology: How Aluminum Nitride Plates Improve Performance

Aluminum nitride (AlN) plates are emerging as pivotal components in the advancement of LED technology. As the demand for efficient and high-performance light-emitting diodes continues to grow, the unique properties of AlN make it an ideal substrate material for LED fabrication. With its exceptional thermal conductivity, aluminum nitride aids in effective heat dissipation, which is crucial for maintaining the longevity and reliability of LED devices. This thermal management capability allows LEDs to operate at higher power levels without compromising their performance.

Moreover, the crystal structure of aluminum nitride enhances the light extraction efficiency of LEDs. By reducing the crystal lattice mismatch between the substrate and the semiconductor layers, AlN plates enable better lattice quality, contributing to increased luminosity and color purity. This improvement not only elevates the overall efficiency of LEDs but also expands their application scope, making it possible to develop brighter and more energy-efficient lighting solutions. As a result, the integration of aluminum nitride plates in LED technology stands as a testament to the innovative strides being made in modern electronics.

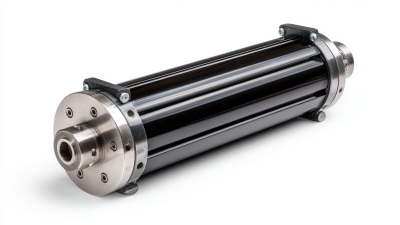

Exploring the Use of Aluminum Nitride in High-Temperature Applications

Aluminum Nitride (AlN) is emerging as a pivotal material in the realm of high-temperature applications, owing to its exceptional thermal conductivity and electrical insulation properties. These attributes make AlN plates a preferred choice in industries that require reliable thermal management solutions, such as aerospace, automotive, and electronics. The global aluminum nitride market is projected to reach a value of $160.4 million in 2024, with an anticipated growth to $169.9 million in 2025, and further expanding to approximately $258.8 million by 2032. This robust market trajectory is a testament to the increasing adoption of AlN in innovative thermal applications.

In high-temperature environments, aluminum nitride proves advantageous due to its high melting point and stability under extreme conditions. Its applications span across semiconductor devices, LED technology, and other advanced electronics, where efficient heat dissipation is crucial for operational reliability. As industries continue to push the boundaries of performance, the demand for aluminum nitride plates will likely rise, driving innovation and expansion within the sector. The ongoing advancements in the production techniques of AlN also promise to enhance its usability, further solidifying its role in modern technology.

Innovative Fabrication Techniques for Aluminum Nitride Plates in Modern Devices

The advancement in fabrication techniques for aluminum nitride (AlN) plates is revolutionizing their application in modern devices. Techniques like chemical vapor deposition (CVD) and laser-based processes allow for the creation of high-purity, precision-engineered AlN plates. These methods enable engineers to produce plates with specific attributes such as enhanced thermal conductivity and dielectric isolation, catering to the growing demands of high-performance electronics and optoelectronics.

**Tip:** When working with AlN plates, it's essential to maintain a controlled environment during the fabrication process to prevent contamination. This can significantly improve the quality and reliability of the final product.

Additionally, innovative methods like additive manufacturing are paving the way for complex geometries and customized designs. By utilizing 3D printing techniques, manufacturers can achieve intricate shapes that were previously unattainable with traditional methods. This flexibility not only streamlines production but also enhances functionality in devices ranging from power electronics to high-frequency components.

**Tip:** It’s beneficial to collaboratively engage with material scientists while designing AlN components, as their expertise can lead to innovative uses and improved product performance tailored to specific applications.

Aluminum Nitride vs. Traditional Materials: A Comparative Analysis of Benefits

Aluminum nitride (AlN) has emerged as a revolutionary material in modern technology, surpassing traditional materials like ceramics and metals in various applications. One of the most notable advantages of AlN is its exceptional thermal conductivity, which allows for efficient heat dissipation in electronic devices. Unlike traditional ceramic materials, which often struggle with thermal management, AlN provides a seamless solution, enhancing the performance and longevity of components such as LED lighting and high-power electronic devices.

Moreover, aluminum nitride boasts a high level of electrical insulation combined with mechanical strength, making it an ideal choice for applications in harsh environments. This contrasts sharply with metals that can corrode and ceramics that can be brittle. The lightweight nature of AlN further adds to its appeal, allowing for reduced overall system weight without compromising strength. As industries increasingly prioritize efficiency and reliability, aluminum nitride stands out as a forward-looking alternative to legacy materials, driving innovation across diverse fields such as telecommunications, automotive, and aerospace.

FAQS

luminum Nitride (AlN) used for in power electronics?

The aluminum nitride market is expected to reach $245.8 million by 2033, reflecting a significant shift towards high-efficiency energy solutions.

AlN enhances energy efficiency by facilitating better thermal management in power converters, thereby reducing energy losses during operation.

Aluminum Nitride is especially beneficial in industries such as aerospace, automotive, and electronics, where reliable thermal management is crucial.

AlN offers high thermal conductivity, electrical insulation, and a high melting point, making it suitable for operating reliably under extreme conditions.

Recent innovations include a heating-assisted laser direct writing technique that creates low-resistance conductive layers on AlN ceramics, enhancing the efficiency of power converters.

AlGaN is emerging in high-performance applications alongside AlN, benefiting from the enhanced thermal properties provided by Aluminum Nitride.

The global demand for aluminum nitride is anticipated to grow substantially, with projections reaching $160.4 million in 2024 and expanding further in subsequent years.

Efficient thermal management is crucial in advanced electronics as it ensures operational reliability by preventing overheating in semiconductor devices and other technologies.

Continued research in substrate engineering and production techniques is expected to enhance AlN's usability, further solidifying its importance in modern energy-efficient technologies.

Conclusion

In the realm of modern technology, Aluminum Nitride Plates are emerging as a game-changer across various applications. Their exceptional thermal conductivity is revolutionizing thermal management in electronics, allowing devices to operate efficiently at high temperatures. Furthermore, these plates play a crucial role in enhancing power electronics, significantly improving energy efficiency and reliability. Innovations in LED technology also highlight the benefits of Aluminum Nitride Plates, as they contribute to better performance and longevity of lighting solutions.

Additionally, Aluminum Nitride's capability to withstand high-temperature environments makes it ideal for advanced applications. With recent advancements in fabrication techniques, the production of Aluminum Nitride Plates has become more efficient, aligning well with the precision ceramic manufacturing expertise at ST.CERA CO., LTD. By advocating for Aluminum Nitride over traditional materials, this comparative analysis uncovers substantial benefits, reinforcing its importance in the future of technology.

Related Posts

-

Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

-

Maximizing ROI: How Our After-Sales Support on Best Shadow Ring Inserts Minimizes Repair Costs

-

7 Essential Tips for Sourcing the Best Silicon Carbide Bushing Globally

-

How to Choose the Best ESD Wafer Arm for Optimal Semiconductor Processing Efficiency

-

How to Choose the Best Silicon Carbide Plates for Your Industrial Needs

-

2025 Trends in Advanced Ceramics: Innovative Solutions for Best Sic Ceramic Fork Applications

Blog Tags: