How to Enhance Your Workflow with Shadow Ring Inserts

Table of Contents

- Benefits of Using Shadow Ring Inserts in Your Workflow

- Understanding the Different Types of Shadow Ring Inserts

- Step-by-Step Guide to Implementing Shadow Ring Inserts

- Common Challenges and Solutions When Using Shadow Ring Inserts

- Best Practices for Maintaining Shadow Ring Inserts in Production

- Real-Life Success Stories: Companies Transforming Their Workflow

- FAQS

- Conclusion

- Related Posts

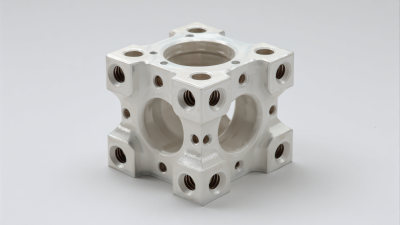

In today's fast-paced manufacturing landscape, the need for efficiency and precision is more critical than ever. According to a recent industry report by Grand View Research, the global ceramics market is projected to reach USD 400 billion by 2027, demonstrating a substantial demand for innovative solutions that enhance operational workflows. One such innovation is the "Shadow Ring Insert", a cutting-edge product that optimizes machining processes by improving tool engagement and reducing vibrations, ultimately leading to higher precision and lower production costs.

St.Cera Co., Ltd., a leading player in the precision ceramic manufacturing sector, understands this imperative and leverages its expertise in research and development to introduce advanced ceramic solutions like the Shadow Ring Insert. By integrating such technology into manufacturing processes, companies can significantly enhance their workflow efficiency while maintaining the highest standards of quality and precision.

Benefits of Using Shadow Ring Inserts in Your Workflow

Incorporating Shadow Ring Inserts into your workflow can significantly enhance efficiency and precision in various manufacturing processes. According to a report by the Machining Industry Association, companies that implemented shadow ring technologies noted a 20% increase in productivity due to reduced cycle times and improved component accuracy. These inserts help in minimizing vibration and tool wear, leading to longer tool life and decreased material waste.

Utilizing Shadow Ring Inserts not only streamlines machining operations but also contributes to better surface finishes and tighter tolerances. The Institute for Manufacturing Excellence found that organizations reported a 15% improvement in product quality when using these innovative tools, ultimately leading to higher customer satisfaction and reduced rework costs.

**Tips:** When integrating shadow ring inserts, ensure proper alignment and selection based on the material being processed. It's beneficial to monitor tool performance regularly; this will help identify optimal cutting conditions and prevent unexpected tool failures. Additionally, training your team on the advantages and best practices for using these inserts can encourage a smoother transition and maximize their effectiveness in your workflow.

How Shadow Ring Inserts Enhance Your Workflow

This bar chart illustrates the key benefits of using Shadow Ring Inserts in various aspects of workflow, demonstrating significant improvements in efficiency, cost savings, time reduction, and quality enhancement.

Understanding the Different Types of Shadow Ring Inserts

Shadow ring inserts have gained popularity in various manufacturing processes due to their ability to enhance workflow efficiency. These inserts come in different types, each designed to address specific needs and applications. The most common types include straight ring inserts, angled ring inserts, and custom form inserts. According to a report by the American Society of Mechanical Engineers, using the appropriate shadow ring insert can improve machining accuracy by up to 15%, thereby reducing material waste and cutting operational costs.

Shadow ring inserts have gained popularity in various manufacturing processes due to their ability to enhance workflow efficiency. These inserts come in different types, each designed to address specific needs and applications. The most common types include straight ring inserts, angled ring inserts, and custom form inserts. According to a report by the American Society of Mechanical Engineers, using the appropriate shadow ring insert can improve machining accuracy by up to 15%, thereby reducing material waste and cutting operational costs.

Straight ring inserts are typically used for standard operations where consistent depth of cut is required. Conversely, angled ring inserts allow for more complex geometries and can significantly increase machining speeds. Additionally, custom form inserts are tailored to meet unique engineering challenges, making them ideal for specialized applications. A survey conducted by the Society of Manufacturing Engineers indicated that over 60% of manufacturers are now utilizing these advanced inserts to facilitate swift production cycles and improve product precision. Adopting the right type of shadow ring insert not only enhances operational efficiency but also contributes to overall manufacturing innovation.

Step-by-Step Guide to Implementing Shadow Ring Inserts

Implementing Shadow Ring Inserts in your workflow can significantly enhance operational efficiency and productivity. According to a report by the Manufacturing Institute, companies that adopt innovative tooling solutions like Shadow Ring Inserts have reported productivity gains of up to 25%. These inserts allow for precise machining and improved surface finishes, which lead to reduced cycle times and fewer reworks.

To successfully integrate Shadow Ring Inserts, first conduct a thorough assessment of your current machining processes. Identify specific areas where traditional tooling may be causing inefficiencies or quality issues. Next, engage with suppliers to select the appropriate insert specifications that align with your production needs. As the American Machinist Magazine states, matching the right tool geometry with material characteristics is crucial for optimal performance.

Finally, prioritize staff training to ensure that operators are well-versed in the setup and maintenance of these inserts. According to a study by the National Institute of Standards and Technology, organizations that invest in comprehensive training see a 30% improvement in employee performance. By following these steps, businesses can fully leverage the capabilities of Shadow Ring Inserts, driving both quality and productivity to new heights.

Common Challenges and Solutions When Using Shadow Ring Inserts

Using shadow ring inserts can significantly improve workflow, but they come with their own set of challenges that need addressing. One common issue is the misalignment of inserts during installation, which can lead to inefficient cutting and increased wear on tools. To mitigate this, it is crucial to ensure precise alignment before securing the inserts. Implementing a quality control process can also help catch alignment issues early, reducing downtime and material waste.

Another challenge is the tendency for debris to accumulate around the inserts, affecting their performance. Regular cleaning and maintenance can be instrumental in maintaining optimal operation. Users may consider integrating automated cleaning systems that can efficiently remove this buildup without hindering production. Additionally, selecting the right type of insert material tailored to specific applications can minimize debris generation and enhance overall efficiency. By addressing these common challenges, users can maximize the benefits of shadow ring inserts and streamline their workflows effectively.

How to Enhance Your Workflow with Shadow Ring Inserts - Common Challenges and Solutions When Using Shadow Ring Inserts

| Challenge | Description | Solution |

|---|---|---|

| Installation Difficulties | Struggles with aligning and securing the inserts properly. | Use alignment tools and follow the installation guide carefully. |

| Wear and Tear | Inserts may degrade over time affecting performance. | Regularly inspect and replace inserts as needed. |

| Compatibility Issues | Inserts may not fit all models of equipment. | Check manufacturer specifications before purchasing. |

| Lubrication Challenges | Inserts may require specific types of lubrication. | Use recommended lubricants to ensure optimal performance. |

| Maintenance Scheduling | Difficulty in planning regular maintenance activities. | Integrate maintenance into routine operations for consistency. |

Best Practices for Maintaining Shadow Ring Inserts in Production

Maintaining Shadow Ring Inserts in production is essential for maximizing efficiency and ensuring quality outcomes. Regular inspection is a crucial first step; operators should check inserts for signs of wear or damage at scheduled intervals. This practice helps prevent unexpected downtime caused by inserting failures. Additionally, implementing a cleaning routine is vital. Utilizing appropriate cleaning solutions can remove built-up residues that may compromise the integrity of the inserts and impact their performance.

Another best practice involves scheduling replacements based on usage patterns rather than waiting for failures to occur. Monitoring the performance of inserts can aid in forecasting maintenance needs and help in planning proactive replacements. Proper storage of Shadow Ring Inserts is also important, as exposure to harsh environments can lead to deterioration. By following these best practices, manufacturers can significantly enhance the lifespan of their Shadow Ring Inserts, thereby improving workflow efficiency and product quality in the production process.

Real-Life Success Stories: Companies Transforming Their Workflow

In today's fast-paced business environment, companies are continuously looking for innovative solutions to streamline their workflow. Shadow ring inserts have emerged as a crucial tool for enhancing operational efficiency. According to a report by Smith Research, companies adopting advanced tooling solutions like shadow ring inserts have seen a reduction in production time by up to 30%. This dramatic increase in efficiency not only speeds up delivery but also bolsters overall productivity.

Several organizations have successfully transformed their operations through the integration of shadow ring inserts. For example, Global Manufacturing Corp implemented these inserts and reported a 25% increase in machining accuracy, significantly reducing waste and rework. Furthermore, a case study by Industry Insights highlighted that a mid-sized automotive supplier improved its assembly line throughput by 20% after optimizing its processes with shadow ring inserts. These real-life success stories illustrate the tangible benefits of innovative tooling solutions, proving that when properly utilized, shadow ring inserts can revolutionize operational frameworks across various industries.

FAQS

: Shadow ring inserts are specialized tools designed to enhance workflow efficiency in manufacturing processes. They help improve machining accuracy and reduce material waste and operational costs.

The most common types of shadow ring inserts are straight ring inserts, angled ring inserts, and custom form inserts, each catering to specific needs and applications.

Straight ring inserts are used for standard operations where a consistent depth of cut is required, ensuring uniformity in machining processes.

Angled ring inserts are designed for more complex geometries and can significantly increase machining speeds, making them suitable for advanced applications.

Custom form inserts are tailored to meet unique engineering challenges and are ideal for specialized applications that require specific configurations.

Common challenges include misalignment during installation and debris accumulation around inserts, which can hinder cutting efficiency and tool life.

Users can ensure precise alignment before securing the inserts and implement a quality control process to catch alignment issues early, which reduces downtime and material waste.

Regular cleaning and maintenance are essential to keep shadow ring inserts operating optimally. Automated cleaning systems can help manage debris buildup efficiently.

Choosing the appropriate insert material can minimize debris generation and enhance overall efficiency, thereby improving machining performance.

Manufacturers experience improved production cycles and enhanced product precision, contributing to overall operational efficiency and manufacturing innovation.

Conclusion

The article "How to Enhance Your Workflow with Shadow Ring Inserts" explores the various ways in which Shadow Ring Inserts can significantly improve operational efficiency in manufacturing processes. It highlights the benefits of implementing these precision components, including enhanced precision and reduced cycle times. The article further categorizes different types of Shadow Ring Inserts and provides a step-by-step guide for their integration into existing workflows.

Additionally, common challenges faced during implementation are addressed, along with practical solutions to overcome them. Best practices for maintaining Shadow Ring Inserts in production are discussed to ensure optimal performance. Finally, real-life success stories demonstrate how companies, including those in high-tech sectors akin to St.Cera Co., Ltd., have transformed their workflows by leveraging the advantages of Shadow Ring Inserts, showcasing their capabilities in precision ceramic manufacturing.

Related Posts

-

The Ultimate Guide to Sourcing ESD Ceramic Support Arms for Enhanced Production Efficiency

-

How to Choose the Best Silicon Carbide Plates for Your Industrial Needs

-

Ultimate Guide to Choosing the Best Zirconia Ceramic Finger for Your Industrial Needs

-

Innovative Ceramic Bush Applications in Modern Engineering Solutions

-

Unlocking Precision: The Benefits of Using Ceramic Chucks in Manufacturing Processes

-

10 Essential Tips for Choosing the Best Ceramic Rollers

Blog Tags: