How to Choose the Right Edge Grip End Effector for Your Automation Needs

Table of Contents

- Understanding Edge Grip End Effectors and Their Importance

- Key Factors to Consider When Selecting End Effectors

- Types of Edge Grip End Effectors and Their Applications

- Material Compatibility for Different Automation Tasks

- Assessing Load Capacity and Grip Strength Requirements

- Evaluating Cost-Effectiveness and Budget Constraints

- Integration with Existing Automation Systems and Processes

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving landscape of automation, choosing the right Edge Grip End Effector can significantly enhance operational efficiency and productivity. According to Dr. Emily Chen, a leading expert in robotic automation at Tech Innovations, "The selection of the appropriate Edge Grip End Effector is crucial for maximizing the capabilities of automated systems." This highlights the importance of understanding the specific requirements of your tasks when selecting an end effector.

As industries increasingly turn to automation solutions to streamline processes, the Edge Grip End Effector emerges as a vital component in robotic applications. These end effectors are designed to securely handle items with edges, providing a reliable grip for various shapes and sizes. With a plethora of options available, it can be daunting for companies to make an informed choice that aligns with their operational needs. In this guide, we will explore key factors to consider when selecting your Edge Grip End Effector, ensuring you make a well-informed decision that drives your automation success.

Understanding Edge Grip End Effectors and Their Importance

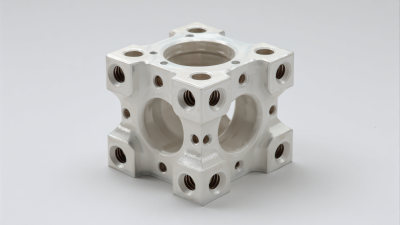

Edge grip end effectors play a crucial role in automation, particularly in applications that require precise positioning and secure handling of objects. These devices are specifically designed to grip items from the edges, making them an ideal choice for handling delicate or irregularly shaped components. By applying pressure only on the edges, edge grip end effectors minimize the risk of damaging the product, which is especially important in industries such as electronics, packaging, and automotive manufacturing.

Understanding the significance of edge grip end effectors is essential for optimizing automation processes. They not only enhance safety and reliability during material handling but also increase the efficiency of operations by allowing for faster and more accurate movements. The ability to adapt these end effectors to various shapes and sizes further underscores their versatility, making them suitable for a wide range of tasks. As automation technology continues to evolve, selecting the right edge grip end effector becomes vital for achieving smooth and effective workflow in production environments, ultimately leading to improved productivity and cost-effectiveness.

Key Factors to Consider When Selecting End Effectors

When selecting an edge grip end effector for automation needs, several key factors play a critical role in ensuring optimal performance and efficiency. First, consider the materials being handled. According to a report by the International Federation of Robotics (IFR), more than 90% of industrial robots are now used for handling parts and materials. The type of materials—whether soft, rigid, or delicate—will determine the grip design and the force applied. Effective end effectors must accommodate variations in size and fragility, which may require customizable pads or adjustable grips.

Another crucial factor is the environment in which the end effector will operate. Research indicates that nearly 25% of manufacturing companies have pointed to harsh environmental conditions as a significant challenge in automation (McKinsey & Company). End effectors exposed to dust, moisture, and extreme temperatures need robust materials and sealing to maintain functionality. It is also essential to consider the integration capabilities with existing robotic systems. A seamless integration reduces downtime and enhances productivity, demonstrating the importance of compatibility with the robot's operational algorithms and control systems. Ultimately, a thoughtful analysis of these factors will enable organizations to tailor their choices to meet specific operational challenges effectively.

How to Choose the Right Edge Grip End Effector for Your Automation Needs - Key Factors to Consider When Selecting End Effectors

| Criterion | Description | Example Applications |

|---|---|---|

| Grip Style | Type of grip mechanism (e.g., pneumatic, mechanical, magnetic) | Handling metal parts, boxes, fragile items |

| Payload Capacity | Maximum weight the end effector can handle | Robotic arms lifting product parts in assembly lines |

| Surface Material | Material of the gripping surface (e.g., rubber, foam, plastic) | Picking delicate objects, packaging |

| Automation Compatibility | Compatible with different robotic systems and controls | Integration with programmable robotic arms |

| Environmental Considerations | Resistance to contaminants, temperature, humidity | Cleanroom applications, outdoor environments |

| Technical Support & Maintenance | Availability of support and ease of maintenance | Routine checks, emergency repairs |

Types of Edge Grip End Effectors and Their Applications

Edge grip end effectors are essential tools in automation, particularly in industries such as packaging, electronics, and automotive. These devices maximize productivity by securely handling items during assembly, packaging, and transportation processes. There are various types of edge grip end effectors, each designed for specific tasks, including vacuum cups, mechanical grippers, and magnetic end effectors. According to a recent study by ResearchAndMarkets, the global market for automation end effectors is projected to reach $4.5 billion by 2025, highlighting the increasing demand for specialized tools in manufacturing.

Vacuum cups are widely used for their ability to handle flat and non-porous materials. They create a vacuum seal that securely grips items without damaging their surface, making them ideal for fragile products. Mechanical grippers, on the other hand, are versatile and can handle various shapes and materials. They are particularly effective in applications requiring a strong grip and delicate handling, such as assembling electronic components. Magnetic end effectors are best suited for ferromagnetic materials and enable quick and seamless transfers, further enhancing operational efficiency.

Tips: When choosing an edge grip end effector, consider the material type and shape of the objects you’ll be handling. It's essential to evaluate the weight capacity and gripping force of the end effector to ensure optimal performance. Additionally, reviewing compatibility with your existing automation system can help streamline your operations and reduce downtime.

Material Compatibility for Different Automation Tasks

When selecting the appropriate edge grip end effector for automation tasks, material compatibility plays a crucial role in ensuring efficiency and effectiveness. Different tasks often require specific materials to optimize performance and minimize wear and tear on equipment. For instance, in environments where delicate items need to be handled, softer materials like silicone or foam might be used to prevent damage. In contrast, for applications involving heavier or more abrasive items, harder materials such as aluminum or reinforced plastics are preferable for their durability and strength.

Moreover, the chemical properties of the materials being manipulated should also influence the choice of end effector. Certain tasks may expose the end effector to corrosive substances or extreme temperatures, necessitating the use of specialized materials such as stainless steel or high-temperature resistant polymers. Understanding the interaction between the end effector materials and the products being handled is essential to maintaining operational integrity and longevity. Therefore, a thorough analysis of both the operational environment and the materials involved is imperative for selecting the right edge grip end effector tailored to specific automation needs.

Material Compatibility of Edge Grip End Effectors for Automation Tasks

Assessing Load Capacity and Grip Strength Requirements

When selecting the right edge grip end effector for your automation applications, assessing load capacity and grip strength requirements is paramount. The load capacity refers to the maximum weight the end effector can handle, while grip strength determines how securely it can hold onto objects, especially during movement. It is crucial to evaluate both of these factors based on the specific materials and sizes of the items you will be handling. This ensures that the end effector performs reliably under expected operating conditions.

Tips: Before making a decision, conduct a thorough analysis of the typical loads your automation system will encounter. Take into account the weight variance of your products and the dynamic forces during transport. Additionally, consider the material properties of the objects being handled, as this can affect grip performance. Testing prototypes in real-world scenarios can provide insights into the effectiveness of your chosen end effector.

Moreover, understanding the environmental conditions in which the end effector operates can significantly impact the selection process. Factors such as temperature, humidity, and exposure to various substances can influence both load capacity and grip strength. Always consult technical specifications and consider any necessary modifications to ensure optimal performance tailored to your automation needs.

Evaluating Cost-Effectiveness and Budget Constraints

When selecting an edge grip end effector for automation, evaluating cost-effectiveness and budget constraints is crucial. Businesses must conduct a thorough analysis of both initial investment and long-term operational costs. According to a report by Research and Markets, the global industrial automation market is expected to grow significantly, projected to reach over $200 billion by 2026, highlighting the increasing importance of cost-efficient solutions in equipment selection. Businesses should not only consider the price of the end effector itself but also evaluate additional factors such as maintenance costs, energy consumption, and potential downtime costs due to inefficiencies.

**Tips:** When assessing cost-effectiveness, take advantage of lifecycle cost analysis (LCCA) to get a comprehensive view of total expenses over the operational life of the edge grip end effector. This method helps identify potential savings and ensure the component selected aligns with your budgetary constraints while meeting performance standards.

Another key consideration in your decision-making process is the compatibility of the end effector with existing systems and processes. A well-suited end effector can minimize integration costs and reduce the risk of operational disruptions. A report by the International Federation of Robotics indicates that approximately 60% of automation failures stem from a mismatch between the robot and the chosen end effector. Investing in a well-matched tool is critical not only for financial prudence but also for optimizing automation efficiency.

Integration with Existing Automation Systems and Processes

When selecting the right edge grip end effector for your automation needs, seamless integration with existing automation systems and processes is crucial. This ensures that the new technology complements your current setup, enhancing productivity without requiring a complete overhaul. Understanding the specifications and compatibility of your existing system will help you make informed choices, minimizing downtime and operational disruptions.

Tips for ensuring smooth integration include assessing the communication protocols of your current systems. Ensuring that the new end effector can effectively communicate with your existing machinery is paramount. Additionally, consider the physical dimensions and mounting capabilities to guarantee a proper fit within your operational environment, avoiding potential compatibility issues.

Another key point is to evaluate the flexibility of the end effector in adapting to various tasks or products. Your automation processes may evolve, so choosing an end effector that can easily be reconfigured or repurposed will provide long-term benefits. Always engage stakeholders during the selection process to address any specific needs or concerns, thereby ensuring that the chosen solution aligns with the overall goals of your automation efforts.

FAQS

: Edge grip end effectors are used to securely handle and precisely position items, particularly delicate or irregularly shaped components, by gripping them from the edges.

They help minimize the risk of damaging products during handling, enhance safety and reliability, and increase operational efficiency by allowing for faster and more accurate movements.

Common types include vacuum cups, mechanical grippers, and magnetic end effectors, each designed for specific handling tasks in automation processes.

Vacuum cups create a vacuum seal to securely grip flat and non-porous materials without damaging their surfaces, making them ideal for handling fragile products.

Consider the material type and shape of the items being handled, the necessary weight capacity, gripping force, and compatibility with existing automation systems.

The choice of end effector material must align with the items being handled to optimize performance, prevent damage, and minimize wear and tear on the equipment.

Softer materials like silicone or foam are advised for delicate items, while harder materials such as aluminum or reinforced plastics are suitable for heavier or more abrasive items.

Understanding the chemical properties helps ensure that the chosen end effector can withstand exposure to corrosive substances or extreme temperatures, affecting its longevity and performance.

They maximize productivity by securely handling items during assembly, packaging, and transportation processes, leading to smoother workflows and improved cost-effectiveness.

Conclusion

The article "How to Choose the Right Edge Grip End Effector for Your Automation Needs" provides a comprehensive guide for selecting the appropriate Edge Grip End Effector tailored to specific automation tasks. It begins by explaining the significance of edge grip end effectors in enhancing operational efficiency and precision in automated systems. Key factors such as material compatibility, load capacity, and grip strength requirements are essential considerations when making a selection.

Additionally, the article discusses various types of edge grip end effectors along with their specific applications across different industries. Cost-effectiveness and budget constraints are also evaluated, ensuring that businesses can make informed decisions without compromising on quality. Finally, the importance of seamless integration with existing automation systems is emphasized, highlighting the need for compatibility in order to optimize overall workflow. By addressing these critical areas, the article serves as a valuable resource for anyone looking to implement edge grip end effectors in their automation processes.

Related Posts

-

Revolutionizing Automation with Advanced Gripper End Effectors for Seamless Operations

-

Innovative Ceramic Bush Applications in Modern Engineering Solutions

-

Why Choose Zirconia Ceramic End Effectors for Precision Applications

-

The Growing Demand for Ceramic Lift Pins at the 2025 China Import and Export Fair

-

Zirconia Ceramic Arm Innovations Shaping Industry Trends at the 138th Canton Fair 2025

-

Maximizing Performance in High Temperature Applications with Alumina Ceramics Supplier Innovations

Blog Tags: