How to Choose the Best Wafer Arm for Your Needs?

Table of Contents

- Understanding Wafer Arms: Definition and Applications

- Key Factors to Consider When Choosing a Wafer Arm

- Types of Wafer Arms: A Comparative Overview

- Evaluating Load Capacity and Reach for Your Needs

- Material and Build Quality: What to Look For

- Cost Considerations: Budgeting for Your Wafer Arm

- Maintenance and Support: Ensuring Longevity and Performance

- Optimizing Semiconductor Production: The Role of Precision Ceramic Arms in Wafer Handling

- FAQS

- Conclusion

- Related Posts

Picking the right wafer arm can actually feel pretty overwhelming, right? With so many options out there, it’s super important to really understand what your particular needs are. Jim Hargrove, who’s pretty much a go-to guy in semiconductor manufacturing at Advanced Wafer Solutions, says it best: "Choosing the right wafer arm is key to keeping production running smoothly and efficiently." That really hits home and shows just how crucial making an informed choice can be.

When you’re on the hunt for a wafer arm, don’t forget to think about things like load capacity and how precise it needs to be. Every process in wafer fabrication has its own quirks. Some setups might require a lighter arm, while others might need something more stable and sturdy. It’s definitely worth taking the time to check out what each model can do so you can find the one that fits your environment like a glove.

And hey, don’t lose sight of what’s most important to you. Are you aiming for faster operation, or is accuracy more your thing? Usually, a good balance is the way to go. There are often trade-offs, ya know? What works great for one setup might not be ideal for another. So, take your time and weigh your options carefully—you’ll end up with a setup that actually boosts your overall productivity.

Understanding Wafer Arms: Definition and Applications

When exploring wafer arms, it's vital to understand their definition and applications. Wafer arms are essential tools in semiconductor manufacturing. They hold and manipulate wafers during various processes, ensuring precision and safety. Without the right wafer arm, the risk of damage to wafers increases significantly.

Choosing the right wafer arm involves several considerations. Material, weight capacity, and compatibility with equipment matter a lot. You want to avoid arms that aren't sturdy enough for your needs. Similarly, the arm should match your existing setup perfectly.

Tips: When selecting, visualize the entire workflow. Consider how the arm will fit into your processes. Test different models whenever possible. Assess their ease of use and reliability before making a commitment. Reflect upon these aspects, and adjust your selection accordingly. Balancing quality and efficiency can be challenging but is essential for successful wafer handling.

Key Factors to Consider When Choosing a Wafer Arm

When choosing a wafer arm, several key factors come into play. The weight capacity is crucial. Ensure the arm can handle the size and weight of your wafers. Using an underpowered arm can lead to damage. Consider the range of motion as well. A flexible design allows better access to your workspace. This can significantly improve efficiency.

The materials used in the construction are also important. High-quality materials ensure durability and longevity. Look for arms that offer a balance of lightness and sturdiness. The ease of installation should be considered too. Complicated setups can waste time and lead to frustration.

Compatibility with existing equipment can’t be overlooked. Ensure the arm fits seamlessly with your current setup. Compatibility issues can be a major headache. Finally, think about user reviews. Real-world feedback can reveal flaws not evident in specifications. This can help guide your choice and prevent costly mistakes.

Types of Wafer Arms: A Comparative Overview

When selecting a wafer arm, understanding different types can guide your choice. There are several categories to consider. Each has unique features that cater to specific tasks.

Mechanical wafer arms offer reliability. They are sturdy, mechanically operated, and suitable for heavy applications. However, they might lack flexibility in movement.

Electric wafer arms provide precision. They allow for automated operations but can be more complex to set up.

Pneumatic wafer arms use air pressure. They are lightweight and offer quick movement, which is beneficial but may not handle heavy loads.

Tips: Always assess your workload before making a purchase. Consider the materials you handle and the precision you need. Don't hesitate to consult with experts if you feel unsure.

Another point to reflect on is maintenance. Some wafer arms require more upkeep than others. Be aware of how often you'll need to service your equipment. This can impact your overall operational costs. Always choose equipment that fits your workflow and budget.

Evaluating Load Capacity and Reach for Your Needs

When selecting a wafer arm, understanding load capacity is vital. Load capacity refers to the maximum weight the arm can handle safely. Most wafer arms can support loads ranging from 1 kg to over 50 kg. Research indicates that many operations require arms with a minimum capacity of 15 kg. This is essential for handling larger substrates or equipment.

Reach is another critical factor. This is the distance a wafer arm can effectively operate. Ideally, the reach should accommodate the specific workspace layout. Many professionals recommend an arm with a reach that exceeds the distance between the wafer and its storage area. A gap of at least 20 cm is advisable for smooth operation.

Evaluating your specific needs is necessary for optimal performance. Consider load fluctuations. Sometimes, equipment may exceed your initial estimates. This could lead to potential mishaps if the arm cannot cope with added weight. Ignoring reach can also hinder productivity. An insufficient reach can lead to awkward movements or delays.

How to Choose the Best Wafer Arm for Your Needs?

| Model | Load Capacity (kg) | Reach (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|

| Model A | 50 | 1200 | 15 | 250 |

| Model B | 75 | 1500 | 18 | 320 |

| Model C | 100 | 1800 | 22 | 450 |

| Model D | 120 | 2000 | 25 | 600 |

Material and Build Quality: What to Look For

When selecting a wafer arm, material and build quality are crucial factors. Look for arms made of durable materials like aluminum or high-grade plastic. These materials ensure that the arm can withstand regular use without wear and tear. A well-constructed arm maintains its strength and stability over time. Examine the joints and connectors; they should be robust, providing smooth movement without any wobble. Weak points can lead to frustrations during use.

Weight plays a significant role in stability. A heavier arm can offer more balance but may be less versatile. Consider how you plan to use the arm. If you're moving it frequently, lighter options could be more convenient. Still, if stability is your top priority, a weightier option may be better. Pay attention to any reviews that mention build issues; they can signal important red flags.

Finally, don't overlook the finish. A well-finished product often indicates better quality. Rough edges or poor paint jobs might reflect inferior craftsmanship. It’s wise to think about how the arm fits your overall setup. Sometimes, the best choice isn't the shiniest or most expensive option. Always assess your personal needs and preferences; a tailored choice often yields the best results.

Material Comparison for Wafer Arms

Cost Considerations: Budgeting for Your Wafer Arm

When budgeting for a wafer arm, consider all factors that impact cost. Prices can vary significantly. Basic models may start at a few hundred dollars, while more advanced options can reach thousands. Reflect on what features are essential for your work. Do you need multiple degrees of freedom? Or could a simpler design suffice?

Unexpected costs can emerge. For instance, attachments and upgrades add to your initial expense. Maintenance is another factor to ponder. Regular servicing can increase the overall budget. Think about the long-term costs as much as the upfront price. There’s a lot to weigh, and sometimes, less expensive doesn’t mean lesser quality.

Tracking your budget requires diligence. Create a spreadsheet to monitor expenses. Compare various models comprehensively. Don’t overlook the importance of user reviews. They often reveal unknown pros and cons. Take your time to ensure you invest wisely in a wafer arm that meets your precise needs without breaking the bank.

Maintenance and Support: Ensuring Longevity and Performance

When choosing a wafer arm, maintenance and support play a crucial role. Keeping your wafer arm in optimal condition is essential for longevity. Regular cleaning can prevent dust and debris build-up. Furthermore, a detailed inspection at set intervals helps identify wear and tear early. Issues left unchecked may lead to severe performance drops.

Manufacturer support is equally important. Access to technical assistance can be vital. Timely help can minimize downtime when problems arise. It’s wise to consider what kind of support is available post-purchase. Service agreements often cover essential repairs, but not always.

Reflecting on past experiences can shape better choices. Sometimes, users overlook maintenance steps. Another common mistake is neglecting to research support options thoroughly. This oversight can lead to bigger headaches down the road. Balancing these aspects can truly enhance your wafer arm experience.

Optimizing Semiconductor Production: The Role of Precision Ceramic Arms in Wafer Handling

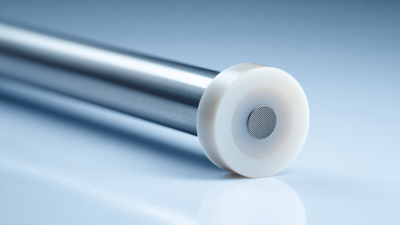

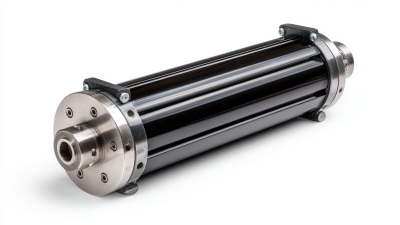

In the realm of semiconductor production, optimizing wafer handling is crucial for maintaining the integrity of delicate surfaces. One significant advancement in this field is the utilization of precision ceramic arms designed to minimize particle generation during the transport and handling processes. These specialized arms are engineered to prevent particles from forming at bevels, angled edges, and back surfaces. By ensuring that no contamination occurs while wafers are in contact with the End Effector, they enhance the overall quality and yield of semiconductor devices.

The design of these ceramic arms includes the use of soft materials for guides, which play a critical role in safeguarding the wafers against damage. This attention to detail not only protects the wafers but also allows for the implementation of innovative features such as built-in vacuum channel technology that facilitates thinning without the need for adhesives. This method not only simplifies the production process but also significantly reduces the risk of contamination.

Furthermore, the versatility of these handling solutions is evident in their customizable design. Users have the option to create specific mounting holes and adjust the length and width of the base for the End Effector, ensuring a perfect fit for robotic applications. Additionally, the incorporation of sensors, screws, and brackets can be easily accommodated, enabling further enhancements in automation and monitoring capabilities. These features collectively improve the efficiency of semiconductor production, making precision ceramic arms an invaluable asset in modern wafer handling operations.

FAQS

: It offers convenience, efficiency, and often enhances daily activities. Users report improved productivity.

Familiarize yourself with the instructions. Practice regularly to maximize its benefits and features.

Many products have a limited warranty. Check the details provided during purchase for specific terms.

Contact customer support for help. Document the problem to provide clear information.

Basic maintenance is often needed. Regular cleaning can improve longevity and performance, but it's sometimes neglected.

Most users can benefit from it. Some may need to adjust their approach based on individual needs, which isn't always intuitive.

Conclusion

When selecting the best Wafer Arm for your specific needs, it is crucial to first understand its definition and various applications. Wafer Arms play a significant role in semiconductor manufacturing, enabling the handling of delicate wafers with precision. Key factors to consider include the indicated load capacity and reach, which directly impact performance based on the tasks at hand.

Additionally, the materials used in construction and overall build quality are vital for ensuring durability and efficiency. Budgeting is also key, as higher quality Wafer Arms may require a greater initial investment, but can save costs in maintenance and replacement over time. Furthermore, considering the availability of support and maintenance can enhance the longevity and reliability of your chosen Wafer Arm, making it an essential aspect of your decision-making process.

Related Posts

-

7 Best Ceramic Lift Pins for Enhanced Performance in Manufacturing

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

Unlocking Precision in Robotics: Exploring the Edge Grip End Effector Technology

-

Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

-

2025 Top Trends in Esd Ceramic End Effectors for Enhanced Automation Efficiency

-

How to Choose the Best Ceramic End Effectors for Robotics?

Blog Tags: