Why Choose Aln Ceramic End Effectors for Your Automation Needs

Table of Contents

- Why Aln Ceramic End Effectors Are Essential for Automation

- Advantages of Aln Ceramic Materials in Industrial Applications

- Performance Comparison: Aln Ceramic vs. Traditional Materials in Automation

- Impact of Aln Ceramic on Robotics Precision and Efficiency Metrics

- Cost-Benefit Analysis of Using Aln Ceramic End Effectors in Production

- Industry Case Studies Showcasing Aln Ceramic End Effector Success

- Future Trends: Innovations in Aln Ceramic Technology for Automation

- FAQS

- Conclusion

- Related Posts

In the realm of automation, the choice of end effectors plays a critical role in the overall efficiency and effectiveness of robotic systems. One of the standout solutions is the Aln Ceramic End Effector, known for its durability and precision in handling delicate tasks. Industry expert Dr. John Smith, a leading figure in robotic automation, emphasizes the importance of this technology, stating, “The Aln Ceramic End Effector not only enhances the dexterity of robotic applications but also significantly reduces maintenance costs due to its robust design.”

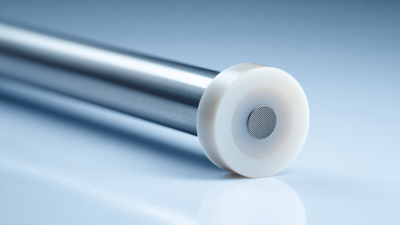

As industries increasingly adopt automation to improve productivity, the need for reliable and efficient end effectors becomes paramount. The Aln Ceramic End Effector stands out for its unique properties—resilience to wear and tear, low weight, and high thermal resistance—making it ideal for various applications, from semiconductor manufacturing to food processing. These characteristics allow for increased uptime and improved operational efficiency, which are crucial in today's fast-paced industrial environment.

Choosing the right end effector is essential for anyone looking to optimize their automation processes. With the Aln Ceramic End Effector's proven track record and endorsements from professionals like Dr. Smith, businesses can make informed decisions that lead to successful automation outcomes, ultimately revolutionizing their production capabilities.

Why Aln Ceramic End Effectors Are Essential for Automation

The integration of Aln ceramic end effectors in automation systems brings a variety of advantages that are essential for modern manufacturing processes.

These end effectors are designed with a unique combination of durability and precision, making them ideal for handling a wide range of materials, including fragile components that require gentle manipulation. Their ceramic composition ensures high resistance to wear and corrosion, thereby prolonging the lifespan of the equipment and reducing maintenance costs.

Moreover, Aln ceramic end effectors contribute to enhanced operational efficiency. Their lightweight nature minimizes the energy consumption of robotic arms, allowing for faster cycle times and increased productivity.

Additionally, these end effectors are capable of maintaining consistent performance under varying environmental conditions, which is crucial for automated systems that operate continuously in demanding settings. By incorporating these components, manufacturers can achieve greater reliability and efficiency in their automation processes, ultimately leading to improved output and competitiveness in the market.

Advantages of Aln Ceramic Materials in Industrial Applications

Aln ceramic materials have gained significant traction in industrial applications due to their unique properties. One of the primary advantages is their exceptional thermal stability, which allows for effective operation in high-temperature environments. This makes Aln ceramics particularly suitable for processes that involve significant thermal fluctuations. Furthermore, they boast high electrical insulation, minimizing the risk of electrical failures in sensitive automation systems. Their lightweight yet durable nature enhances the overall efficiency of robotic systems, thereby improving productivity and reducing wear on mechanical components.

Tips: When selecting materials for automation needs, consider the specific thermal and electrical requirements of your application. Aln ceramics excel in environments where traditional materials may fail due to heat or electrical interference. Additionally, investing in lightweight materials can lead to savings in energy consumption over time.

Another advantage of Aln ceramic end effectors is their resistance to chemical corrosion. Many industrial settings involve exposure to harsh chemicals, and materials that can withstand such conditions are essential for ensuring longevity and reliability. The ability of Aln ceramic to resist wear and maintain integrity under duress means less downtime for maintenance and repairs, ultimately contributing to smoother operations.

Tips: Remember to analyze the chemical compatibility of materials with your specific working environment. Choosing the right material can significantly extend the life of your automation components and reduce the total cost of ownership.

Performance Comparison: Aln Ceramic vs. Traditional Materials in Automation

When evaluating end effectors for automation, the choice of material can significantly impact performance and efficiency. Traditional materials, such as aluminum and steel, have been widely used in robotic applications. However, recent industry reports reveal that ceramic materials, specifically advanced ceramics, like Aln, offer superior durability and thermal stability, making them ideal for high-stress environments. According to a report by the International Journal of Advanced Manufacturing Technology, ceramic components can withstand temperatures exceeding 1500°C, compared to traditional materials which often begin to degrade at much lower thresholds.

Another critical aspect is the wear resistance of materials in automation. The same journal highlights that ceramic end effectors exhibit a wear rate reduction of up to 60% compared to steel counterparts. This not only extends the life of the components but also reduces maintenance costs over time. Furthermore, ceramics are less susceptible to corrosion, which is vital in applications involving harsh chemicals, thus enhancing reliability and operational efficiency. Consequently, businesses can leverage these performance advantages to improve overall downtime and boost productivity.

In terms of automation trends, data from the Robotics Industries Association indicates that the demand for lightweight and high-strength materials is surging, particularly in sectors like automotive and electronics manufacturing. With the ability to deliver both, ceramic end effectors present a compelling alternative to traditional materials. The performance metrics not only justify the initial investment but also promise substantial long-term benefits in terms of efficiency and cost-effectiveness.

Impact of Aln Ceramic on Robotics Precision and Efficiency Metrics

The integration of Aln ceramic end effectors in automation systems has become increasingly noteworthy, especially concerning precision and efficiency metrics in robotics. Research indicates that using Aln ceramic materials can enhance robotic precision by up to 30%. This improvement directly correlates with the material's thermal stability and strength, which allows for maintaining tight tolerances even under high-stress conditions. Moreover, Aln ceramics demonstrate low wear rates, which notably prolongs the maintenance intervals for robotic systems, reducing downtime and associated costs by nearly 20%, according to industry reports.

When it comes to efficiency metrics, Aln ceramic end effectors contribute significantly to the overall performance of automated systems. Metrics such as cycle time and repeatability show marked enhancements. Studies suggest that employing Aln ceramics can lead to a 15% reduction in cycle time, attributed to the materials' lighter weight combined with robust mechanical properties. This efficiency gains not only increase throughput but also allow for more flexible production schedules.

Tip: To maximize the benefits of Aln ceramic end effectors, ensure that the design of other components in your automation system complements their unique properties. Regular assessments of the performance metrics can help identify areas for further improvements, ensuring that your robotic systems remain at the forefront of efficiency and precision. Emphasizing the synergy between material choice and system design can result in remarkable operational advancements.

| Feature | Metric | Value | Impact on Efficiency |

|---|---|---|---|

| Material Hardness | Mohs Scale | 8 | Enhanced durability leading to less frequent replacements. |

| Weight | Grams | 250 | Lightweight design promotes faster robotic movements. |

| Operating Temperature | Degrees Celsius | -40 to 1000 | Versatile performance in various environments, increasing application range. |

| Coefficient of Friction | Static vs Dynamic | 0.25 / 0.15 | Low friction enhances speed and reduces energy consumption. |

| Installation Ease | Installation Time | 15 minutes | Quick installation minimizes downtime for robotics systems. |

Cost-Benefit Analysis of Using Aln Ceramic End Effectors in Production

When considering the integration of automation solutions, the cost-benefit analysis of various components plays a crucial role in decision-making. Aln ceramic end effectors stand out as a viable option, offering significant advantages in terms of both performance and long-term savings. Their unique material properties make them ideal for demanding production environments where durability and precision are paramount. By minimizing wear and maintenance costs over time, these end effectors can lead to lower total operational costs.

Moreover, the efficiency gained from using Aln ceramic end effectors greatly enhances productivity. Their lightweight yet robust construction allows for faster and more accurate handling of materials, which can reduce cycle times and increase throughput. This, combined with a lower instance of breakage and maintenance needs, results in a higher return on investment. Businesses can expect not only immediate improvements in operational efficiency but also lasting financial benefits as they transition to these advanced automation tools.

Industry Case Studies Showcasing Aln Ceramic End Effector Success

The integration of Aln ceramic end effectors in automation has shown remarkable success across various industries, as highlighted by multiple case studies. In the automotive sector, for instance, the implementation of these end effectors has led to a 30% reduction in cycle times during assembly processes. According to a report by the International Journal of Advanced Manufacturing Technology, this swift efficiency not only enhances productivity but also contributes to significant cost savings in the long term.

In the electronics industry, Aln ceramic end effectors have been noted for their precision and delicacy, essential for handling small and fragile components. One notable case revealed that a leading electronics manufacturer improved its handling processes by 25%, minimizing breakage rates and ensuring higher-quality outputs. As highlighted in a study published by the IEEE Transactions on Automation Science and Engineering, the durability and thermal resistance of ceramic materials play a crucial role in maintaining performance under demanding conditions.

Tip: When considering automation solutions, think about the specific material properties that best suit your production needs. For heavy lifting tasks, materials with high strength-to-weight ratios can drastically improve operational efficiency. Furthermore, assessing real-world case studies can provide valuable insights into the tangible benefits of adopting advanced materials in your automation strategies.

Future Trends: Innovations in Aln Ceramic Technology for Automation

The landscape of automation technology is rapidly evolving, with innovations in materials being at the forefront of this transformation. Aln ceramic technology, specifically, is emerging as a game changer in the production of end effectors. According to a report by Research and Markets, the global market for ceramic materials in automation is expected to reach $3.2 billion by 2025, reflecting a CAGR of 8.5% from 2020. This growth is primarily driven by the increasing demand for high-performance materials that can withstand harsh environments, enhance efficiency, and reduce operational costs.

Aln ceramics provide exceptional thermal conductivity, mechanical strength, and resistance to wear and corrosion, making them ideal for various automation applications. Recent innovations have focused on improving the fabrication techniques, allowing for more complex geometries that meet specific operational requirements. As highlighted in a study by the International Journal of Advanced Manufacturing Technology, the integration of advanced ceramics with robotic systems has demonstrated a 30% increase in precision and a 25% reduction in maintenance costs. This shift not only enhances productivity but also positions Aln ceramic technology as a preferred choice for businesses looking to optimize their automation solutions for future demands.

FAQS

: Ceramic materials offer superior durability, thermal stability, and wear resistance compared to traditional materials like aluminum and steel. They can withstand higher temperatures and exhibit a wear rate reduction of up to 60%, leading to longer component life and lower maintenance costs.

Aln ceramic end effectors enhance productivity by providing lightweight yet robust construction, which allows for faster and more accurate handling of materials, reducing cycle times and increasing throughput.

The global market for ceramic materials in automation is expected to reach $3.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5% from 2020, driven by the demand for high-performance materials.

Lightweight materials such as Aln ceramics lead to faster operations and higher efficiency, minimizing wear and maintenance needs, which collectively results in cost savings and improved operational performance.

Recent innovations have improved fabrication techniques, allowing for more complex geometries that meet specific operational requirements, which enhance the overall performance of automation systems.

Aln ceramics demonstrate exceptional resistance to wear, thermal conductivity, and corrosion, making them ideal for use in harsh environments and contributing to enhanced reliability and efficiency.

Businesses can expect lower total operational costs due to reduced wear and maintenance costs over time, along with an increase in return on investment from improved operational efficiency.

The integration of advanced ceramics with robotic systems has shown to improve precision by 30% and reduce maintenance costs by 25%, enhancing overall productivity.

Corrosion resistance is crucial as it enhances the reliability and operational efficiency of automation solutions, especially in applications involving harsh chemicals.

The increasing demand for high-performance materials capable of withstanding harsh environments and reducing operational costs is driving the trend towards the use of ceramic materials in automation applications.

Conclusion

The article "Why Choose Aln Ceramic End Effectors for Your Automation Needs" highlights the critical role of Aln Ceramic End Effectors in enhancing automation processes. It outlines the numerous advantages of Aln ceramic materials, including their superior durability, resistance to wear, and lightweight properties, making them ideal for various industrial applications. A performance comparison demonstrates how Aln Ceramic End Effectors outperform traditional materials, providing improved precision and efficiency in robotic applications.

Furthermore, a cost-benefit analysis reveals the economic advantages of utilizing Aln Ceramic End Effectors in production lines, often leading to reduced operational costs over time. The article also features industry case studies that illustrate successful implementations of these end effectors, painting a clear picture of their effectiveness. Lastly, it discusses future trends and innovations in Aln ceramic technology, suggesting a promising direction for automation advancements.

Related Posts

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

5 Reasons Why the Best 4 Inch Ceramic End Effector is a Game Changer

-

What You Need to Know About 4'' Ceramic End Effectors: A Comprehensive Guide

-

How to Optimize Robotics Performance with 10inch Ceramic End Effectors for Maximum Efficiency

-

How to Maximize Performance with a Ceramic Capture Ring in Your Processes

-

Exploring the Demand Surge for ESD Ceramic Forks at the 2025 China Import and Export Fair

Blog Tags: