Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

Table of Contents

- Identifying Your Specific Business Requirements for Beo Ceramic Tubes

- Assessing Quality Standards and Certifications for Ceramic Tubes

- Understanding Different Types and Applications of Beo Ceramic Tubes

- Evaluating Suppliers: Key Questions to Ask for Reliable Sourcing

- Comparing Prices vs. Quality: Making the Right Investment Choice

- Tips for Negotiating Contracts and Ensuring Timely Deliveries

- FAQS

- Related Posts

In today's competitive landscape, sourcing the right materials is essential for any business aiming to thrive, and the Beo Ceramic Tube stands out as a remarkable choice for various applications. At ST.CERA CO., LTD., a pioneering high-tech enterprise specializing in precision ceramic manufacturing, we understand the importance of selecting the best components to meet your specific needs. With a team of top-ranking experts and engineers dedicated to research and development, we have honed our expertise in creating precision ceramic parts that not only enhance product performance but also ensure durability and reliability. In this ultimate checklist, we will explore the essential factors to consider when sourcing Beo Ceramic Tubes, including quality, compatibility, and potential alternatives that can further optimize your business operations. Embrace the potential that the right Beo Ceramic Tube can unlock for your enterprise as we guide you through this comprehensive evaluation process.

Identifying Your Specific Business Requirements for Beo Ceramic Tubes

When sourcing Beo ceramic tubes for your business needs, it’s essential to first identify your specific requirements. Recent studies highlight the importance of understanding the precise application for which the ceramic is intended. For example, beryllium oxide (BeO) is recognized for its high-temperature radiation stability and density, making it an excellent choice for extreme reactor environments where durability and performance under stress are critical. Industry reports indicate that the ceramic substrate market is projected to reach significant growth figures, underscoring the increasing demand for reliable materials in various applications.

Moreover, advancements in manufacturing techniques, such as the constant evaluation of sintering properties, enable the production of BeO ceramics with tailored characteristics. Research has shown that the sintering process, influenced by temperature and time parameters, can significantly enhance the performance of ceramic materials. Such considerations are crucial when choosing the right supplier, as they can directly impact the effectiveness and lifespan of the tubes in operational environments. Understanding these nuances will help businesses align their specific needs with the appropriate technologies and partners in the ceramic industry.

Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

| Dimension | Material Type | Application | Temperature Resistance | Price Range |

|---|---|---|---|---|

| 10mm x 20mm | Alumina | Electronics | Up to 1500°C | $10 - $15 |

| 15mm x 25mm | Zirconia | Medical | Up to 1200°C | $20 - $25 |

| 20mm x 30mm | Porcelain | Food Processing | Up to 800°C | $15 - $20 |

| 25mm x 35mm | Silica | Industrial | Up to 1000°C | $12 - $18 |

Assessing Quality Standards and Certifications for Ceramic Tubes

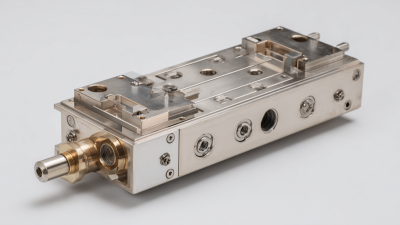

When sourcing the best Beo ceramic tubes for your business, assessing quality standards and certifications is crucial. High-quality ceramic tubes are essential for ensuring durability and performance in various applications, from industrial manufacturing to medical devices. Look for manufacturers that adhere to recognized industry standards such as ISO 9001, which signifies a commitment to quality management systems. Additionally, certifications like ASTM or CE may indicate that the products have been tested under stringent conditions, ensuring safety and reliability.

Another important aspect to consider is whether the ceramic tubes have been tested for specific properties relevant to your needs, such as thermal stability, mechanical strength, and chemical resistance. Certifications from independent testing organizations can provide an additional layer of assurance about the product’s capabilities. By carefully evaluating the certifications and quality standards associated with the Beo ceramic tubes you are considering, you can make an informed decision that aligns with your business needs and maintains a competitive edge in your industry.

Understanding Different Types and Applications of Beo Ceramic Tubes

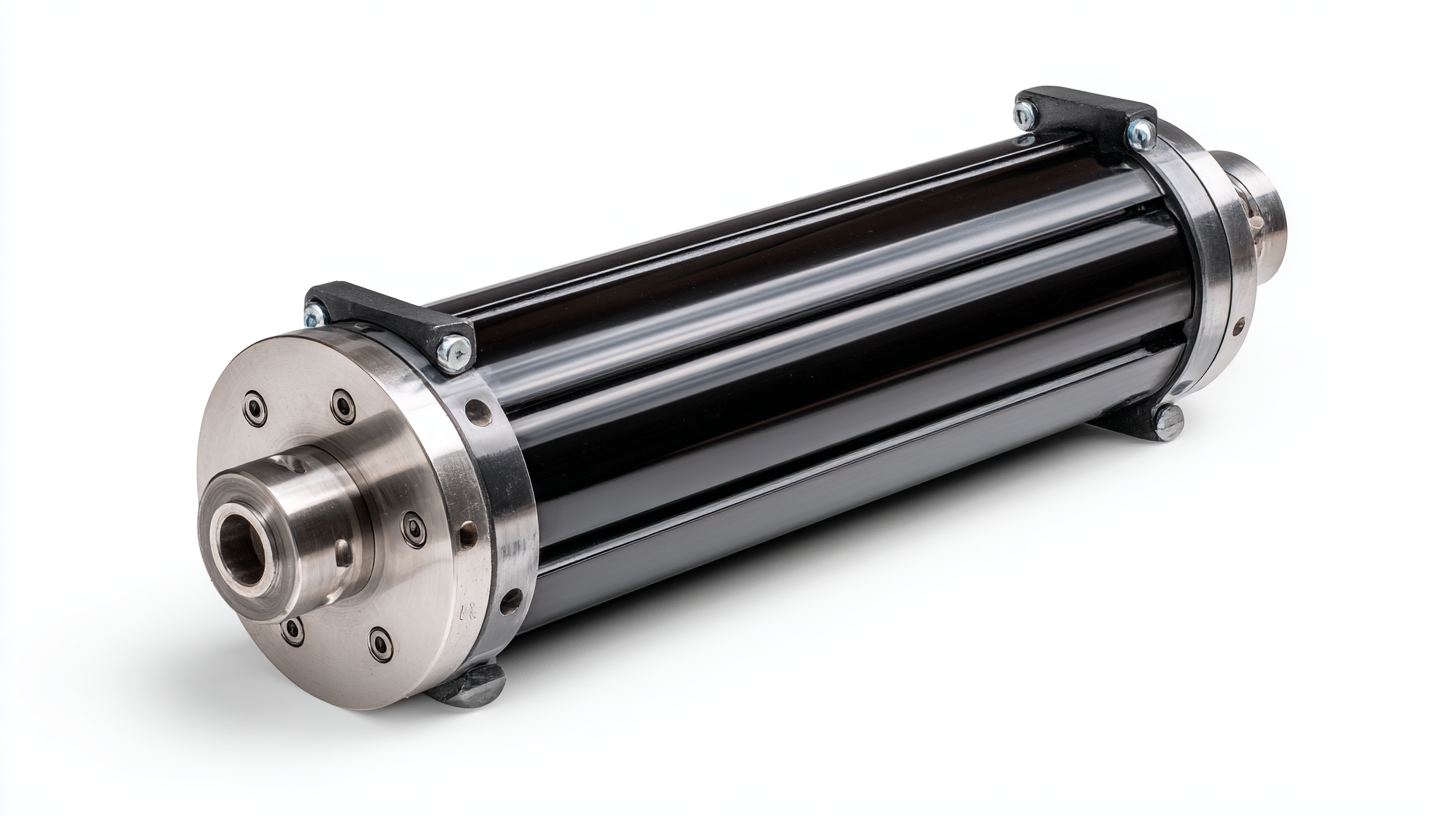

When sourcing Beo ceramic tubes for your business needs, understanding the different types and their applications is crucial for optimizing performance and efficiency. Beo ceramic tubes come in various materials, thicknesses, and sizes, tailored for specific uses. For instance, alumina tubes are renowned for their excellent thermal stability and high mechanical strength, making them ideal for high-temperature applications in the automotive and aerospace industries. On the other hand, zirconia tubes boast superior wear resistance, an excellent choice for environments subjected to abrasion and corrosion.

Another consideration is the application scope of each type of Beo ceramic tube. In chemical processing, for example, tubes that can withstand corrosive environments are vital, and choosing the right composition will directly impact the longevity and safety of operations. Similarly, in the electronics sector, low dielectric loss ceramic tubes are essential for efficient signal transmission. By comprehensively assessing the specific requirements and application contexts of the Beo ceramic tubes, businesses can ensure they select the most suitable products that align with their operational goals and enhance their overall productivity.

Evaluating Suppliers: Key Questions to Ask for Reliable Sourcing

When sourcing Beo ceramic tubes for your business needs, evaluating suppliers is crucial to ensuring quality and reliability. One important aspect to consider is the supplier's production capacity. According to a recent report by Market Research Future, the demand for high-grade ceramic materials is expected to grow at a CAGR of 5.8% from 2022 to 2030. This highlights the importance of collaborating with suppliers who can scale their operations to meet your increasing demands without compromising on quality.

Another critical question to ask potential suppliers revolves around their quality assurance practices. A study from the International Journal of Applied Ceramic Technology reveals that 85% of production failures stem from inadequate quality control measures. Therefore, it is vital to inquire about the testing methods they employ and certifications they hold. Engaging suppliers who adhere to international quality standards, such as ISO 9001, not only mitigates risks but also enhances your product's marketability. Understanding these factors will lead to more reliable sourcing decisions that align with your business objectives.

Supplier Evaluation Criteria for Beo Ceramic Tube Sourcing

This chart illustrates the evaluation scores of key criteria when sourcing the best Beo ceramic tube suppliers. Scores are based on a scale from 1 to 10, allowing businesses to compare potential suppliers effectively.

Comparing Prices vs. Quality: Making the Right Investment Choice

When sourcing the best Beo ceramic tube for your business needs, it’s essential to strike a balance between price and quality. While it may be tempting to choose the least expensive option, the long-term implications of such a decision can be costly. Inferior quality tubes may lead to premature failure, necessitating additional purchases and creating potential disruptions in your operations. Therefore, understanding the material specifications and manufacturing processes of Beo ceramic tubes becomes crucial in assessing their value.

Investing in higher-quality Beo ceramic tubes can yield significant returns in performance and durability. Look for suppliers that emphasize quality control and have a proven track record. While the upfront costs may be higher, these tubes are likely to offer better resistance to wear and chemical corrosion, ensuring that your investment lasts longer. When comparing prices, consider not only the immediate expense but also the lifecycle costs associated with maintenance and replacement. Making the right investment choice today can safeguard your business against future expenses and enhance overall productivity.

Tips for Negotiating Contracts and Ensuring Timely Deliveries

When sourcing the best Beo ceramic tubes for your business needs, negotiating favorable contracts is crucial. Start by establishing clear objectives that align with your company's requirements. Consider factors such as pricing, quality standards, and delivery timelines. Providing suppliers with detailed specifications and an understanding of your operational constraints can incentivize them to offer more competitive terms. Cultivating a collaborative relationship during negotiations can lead to more favorable outcomes, as suppliers may be more willing to adjust their offers when they feel invested in a long-term partnership.

Equally important is ensuring timely deliveries. To achieve this, it’s vital to include clear delivery timelines within your contracts. Incorporate clauses that outline penalties for late deliveries, which hold suppliers accountable. Regular communication is key; maintaining a transparent dialogue with suppliers regarding production progress and potential delays can help mitigate risks. By combining effective negotiation techniques with proactive supply chain management, you can secure a reliable source of Beo ceramic tubes that meets your operational needs while fostering a strong business relationship.

FAQS

: Quality standards and certifications ensure that the ceramic tubes meet durability and performance requirements essential for various applications, ultimately ensuring safety and reliability.

Manufacturers should adhere to recognized industry standards such as ISO 9001, which indicates a commitment to quality management systems, alongside certifications like ASTM or CE.

Certifications from independent testing organizations provide assurance that the ceramic tubes have been tested for specific properties like thermal stability, mechanical strength, and chemical resistance, enhancing buyer confidence in the product’s capabilities.

Contracts should include clear objectives, detailed specifications, pricing, quality standards, and delivery timelines to incentivize suppliers to offer competitive terms.

Businesses can ensure timely deliveries by incorporating clear delivery timelines in contracts, outlining penalties for late deliveries, and maintaining regular communication with suppliers regarding production progress.

Regular and transparent communication with suppliers helps mitigate risks related to potential delays and fosters a collaborative relationship, leading to more favorable outcomes in negotiations.

Businesses should ensure that ceramic tubes are tested for properties such as thermal stability, mechanical strength, and chemical resistance relevant to their specific applications.

A collaborative relationship encourages suppliers to be more accommodating and willing to adjust terms and offers, resulting in better deals for companies.

Not including delivery penalties may lead to inconsistent supply and delays, as suppliers might not feel accountable for late deliveries, which can disrupt operational efficiency.

Carefully evaluating quality certifications allows businesses to make informed decisions that enhance their operational capabilities, thereby maintaining a competitive edge in their industry.

Related Posts

-

How to Choose the Best Sapphire Tube: Essential Metrics and Industry Insights for Global Buyers

-

Ultimate Guide to Sourcing the Best Sic Wafer Arm for Your Manufacturing Needs

-

Ultimate Guide to Sourcing the Best Ceramic C-Shape Rings for Global Markets

-

How to Choose the Best Silicon Carbide Plates for Your Industrial Needs

-

2025 Trends in Advanced Ceramics: Innovative Solutions for Best Sic Ceramic Fork Applications

-

Unmatched Quality: Discover the Excellence of China's Premier Zirconia Ceramic Pin Manufacturer

Blog Tags: