Challenges Faced with Esd Ceramic Arm in Manufacturing Processes

Table of Contents

- Understanding the Unique Properties of ESD Ceramics in Manufacturing

- Identifying Common Manufacturing Challenges with ESD Ceramic Arms

- Strategies for Minimizing Defects in ESD Ceramic Arm Production

- Innovative Solutions for Improving ESD Ceramic Arm Performance

- Best Practices for Quality Control in ESD Ceramic Manufacturing

- Future Trends and Developments in ESD Ceramic Arm Technology

- FAQS

- Conclusion

- Related Posts

In the realm of advanced manufacturing, the integration of ESD ceramic arms has emerged as a pivotal innovation, particularly within high-tech enterprises like ST.CERA CO., LTD. Renowned for its expertise in precision ceramic manufacturing, ST.CERA has encountered a series of challenges associated with the production processes of ESD ceramic arms. These challenges range from material selection to the intricacies of design and fabrication, all of which necessitate a deep understanding of both engineering principles and the unique properties of ceramics. As a leader in the field, ST.CERA's commitment to research and development allows it to navigate these complexities, striving to enhance the efficiency and reliability of ESD ceramic arms. This blog will delve into the specific problems encountered in the manufacturing processes of ESD ceramic arms, examining their implications and proposing solutions to overcome them, ultimately elevating the standards of quality and performance in precision ceramic applications.

Understanding the Unique Properties of ESD Ceramics in Manufacturing

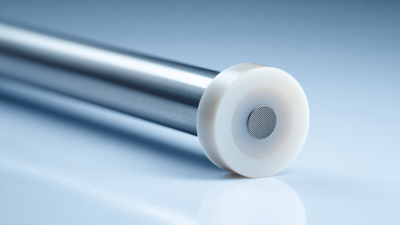

The unique properties of ESD (electrostatic discharge) ceramics play a crucial role in manufacturing processes, particularly in industries where sensitive electronic components are involved. ESD ceramics are engineered to prevent the buildup of static electricity, which can lead to damage or malfunction of electronic devices. This characteristic is vital, as traditional materials often possess high resistivity, making them susceptible to static charge accumulation. By integrating ESD ceramics into manufacturing workflows, companies can significantly reduce the risk of electrostatic discharge events, enhancing the reliability and longevity of their products.

In addition to their static control properties, ESD ceramics offer mechanical strength and durability, making them suitable for various applications. Their resistance to chemical corrosion and high temperatures ensures that they maintain performance under challenging conditions. However, the challenge lies in their processing techniques, as ESD ceramics can be more difficult to mold and shape compared to conventional materials. Manufacturers must adapt their techniques and equipment to accommodate these unique materials, which may involve a steep learning curve. As the demand for sensitive electronic components continues to rise, understanding the properties and challenges of ESD ceramics will be paramount for manufacturers aiming to stay competitive in the market.

Challenges Faced with ESD Ceramic Arm in Manufacturing Processes

Identifying Common Manufacturing Challenges with ESD Ceramic Arms

The manufacturing of ESD ceramic arms presents unique challenges that require careful consideration and innovative solutions. One of the most common issues encountered is the difficulty in achieving consistent material quality. Variations in the ceramic composition can lead to differences in electrical resistance properties, affecting the overall performance of the ESD arms. Manufacturers must establish strict quality control measures to monitor the materials used throughout the process, ensuring that each batch meets the necessary specifications for optimal functionality.

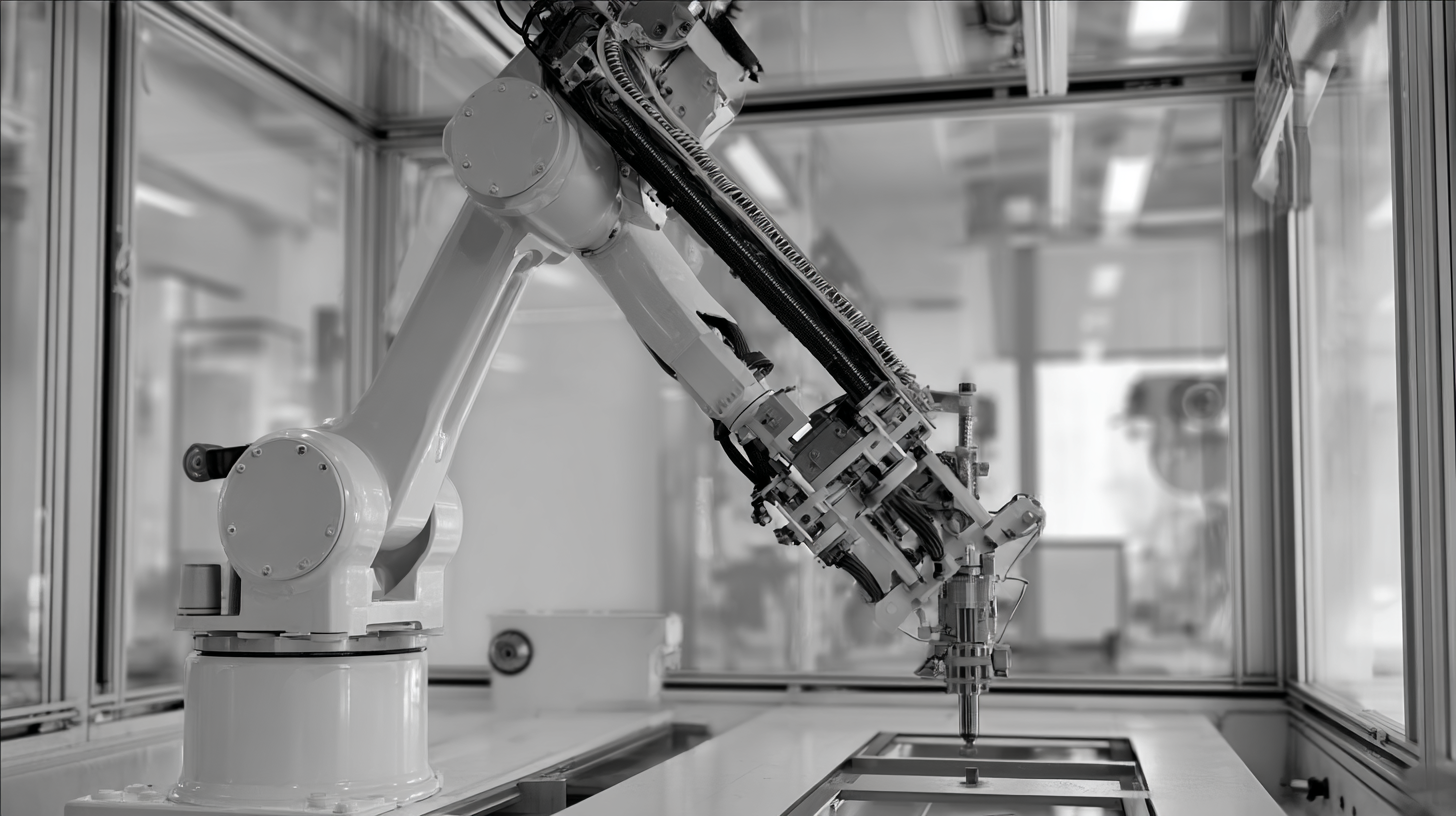

Another challenge lies in the complexity of the manufacturing process itself. ESD ceramic arms often require intricate designs that can complicate production techniques. Precision during cutting and shaping is crucial; any errors can compromise the integrity of the arm, resulting in defects and increased waste. Implementing advanced manufacturing technologies, such as 3D printing or CNC machining, can help mitigate these risks by enhancing accuracy and reducing the likelihood of human error. As manufacturers navigate these common hurdles, ongoing research and development will play a vital role in improving efficiency and product reliability in the production of ESD ceramic arms.

Challenges Faced with ESD Ceramic Arm in Manufacturing Processes

| Challenge | Description | Impact on Production | Proposed Solutions |

|---|---|---|---|

| Surface Fragility | ESD ceramics can be easily scratched or chipped during handling. | Increased replacement costs and production delays. | Implement protective handling procedures and use softer materials for contact. |

| Thermal Sensitivity | ESD ceramics may experience physical property changes under extreme temperatures. | Potential failures in applications requiring high precision. | Adopt temperature monitoring and control in manufacturing areas. |

| Dimensional Tolerances | Maintaining tight tolerances is challenging during the sintering process. | Risk of unusable parts, leading to waste. | Optimize sintering parameters and continuously monitor outputs. |

| Electrical Conductivity Variation | Variations in the manufacturing process can lead to inconsistent conductivity. | Impact on product performance in ESD-sensitive applications. | Standardize material sourcing and processing methods. |

| Cost of Raw Materials | High costs associated with quality raw materials for ESD ceramics. | Higher production costs affecting competitiveness. | Explore alternative suppliers and bulk purchasing options. |

Strategies for Minimizing Defects in ESD Ceramic Arm Production

The production of ESD ceramic arms presents unique challenges that can lead to defects if not properly managed. One of the primary strategies for minimizing these defects revolves around strict quality control throughout the manufacturing process. Implementing rigorous inspection protocols at each stage of production ensures that any inconsistencies or potential problems are identified early. This includes monitoring the raw materials for purity and consistency, as well as closely observing the sintering process, which is critical for the endurance and conductivity of the final product.

Another effective approach involves investing in advanced manufacturing technologies. Utilizing automated systems for precision machining can significantly reduce human error, a common source of defects. Additionally, embracing real-time data analytics enables manufacturers to track and analyze production metrics, allowing for immediate adjustments to be made when deviations from the standard process occur. By adopting these strategies, manufacturers can enhance the quality of ESD ceramic arms while reducing waste and improving overall efficiency.

Innovative Solutions for Improving ESD Ceramic Arm Performance

The performance of ESD ceramic arms in manufacturing processes can be significantly improved through innovative solutions that leverage advanced technologies. One promising direction is the integration of AI-powered systems, which can optimize manufacturing workflows and enhance the precision of ESD products.

Similar to recent developments in the tech industry where companies have adopted AI to refine service delivery and operational efficiency, the ESD ceramic arm sector can benefit from machine learning algorithms that analyze manufacturing metrics in real-time, allowing for immediate adjustments and reductions in waste.

Furthermore, partnerships between technology experts and manufacturing firms can foster the development of specialized tools and systems tailored for ESD applications. Collaboration on semiconductor product improvements and production testing can serve as a model for ESD manufacturers aiming to innovate.

By merging expertise in materials science with cutting-edge design and testing methodologies, the industry can transcend traditional limitations, yielding more durable and efficient ESD ceramic arms that cater to the evolving demands of modern manufacturing environments.

Best Practices for Quality Control in ESD Ceramic Manufacturing

In the realm of manufacturing ESD (Electrostatic Discharge) ceramic arms, ensuring quality control is paramount to meet industry standards. A study by the Research Institute of Electronics and Materials (RIEM) indicates that over 30% of defects in ESD ceramics arise during the manufacturing phase, specifically due to inconsistent raw material quality and processing methods. This highlights the necessity for stringent quality control measures throughout the production process.

Implementing best practices such as rigorous supplier assessments and in-process monitoring can significantly mitigate these risks. The American Society for Testing and Materials (ASTM) specifies that ESD ceramics must maintain surface resistivity within the range of 104 to 109 ohms for optimal performance. By utilizing advanced methods such as X-ray diffraction (XRD) and scanning electron microscopy (SEM), manufacturers can not only ensure adherence to these standards but also enhance product reliability.

Investing in automated inspection technologies has also been shown to improve defect detection rates by up to 40%, thereby facilitating a more robust quality assurance framework in ESD ceramic production.

Future Trends and Developments in ESD Ceramic Arm Technology

The future of ESD ceramic arm technology looks promising as manufacturers increasingly prioritize static control in sensitive environments. Emerging advancements in materials science are enhancing the dielectric properties of ESD ceramics, making them more effective in dissipating electrostatic charges. Innovations, such as the integration of nanomaterials into ceramic composites, are expected to improve mechanical strength while maintaining essential electrostatic discharge (ESD) characteristics. This trend not only increases the operational lifespan of ceramic arms but also maintains their lightweight and ergonomic design, crucial for efficiency in manufacturing processes.

Moreover, the integration of smart technologies into ESD ceramic arms is set to revolutionize their functionality. The development of embedded sensors that monitor environmental conditions in real-time could provide critical data for predictive maintenance and enhance the overall effectiveness of ESD workflows. Furthermore, as industries move toward automation and the Internet of Things (IoT), ESD ceramic arms could become key components in automated systems, ensuring optimal safety and performance. This convergence of advanced materials and smart technology holds significant potential for driving the future of ESD solutions in manufacturing.

FAQS

: ESD ceramics are specialized materials designed to prevent the buildup of static electricity, which is crucial for protecting sensitive electronic components in manufacturing processes.

ESD ceramics help minimize the risk of electrostatic discharge events that can damage electronic devices, enhancing their reliability and longevity, especially in industries involving sensitive components.

ESD ceramics offer mechanical strength and durability, as well as resistance to chemical corrosion and high temperatures, making them suitable for various demanding applications.

ESD ceramics can be more difficult to mold and shape compared to traditional materials, requiring manufacturers to adapt their techniques and equipment, often resulting in a steep learning curve.

Strict quality control throughout the manufacturing process, including rigorous inspection protocols and monitoring of raw materials and the sintering process, is essential to minimize defects in ESD ceramic arms.

Investing in advanced manufacturing technologies, such as automated systems for precision machining and real-time data analytics, can significantly reduce human error and allow for immediate adjustments during production.

Implementing rigorous supplier assessments, in-process monitoring, and utilizing advanced methods like X-ray diffraction and scanning electron microscopy can enhance quality control in ESD ceramic manufacturing.

ESD ceramics must maintain a surface resistivity within the range of 10^4 to 10^9 ohms to ensure optimal performance according to the American Society for Testing and Materials (ASTM) standards.

Automated inspection technologies can enhance defect detection rates by up to 40%, allowing for a more robust quality assurance framework in ESD ceramic production.

Inconsistent raw material quality is a significant contributor to defects in ESD ceramics; thus, monitoring and ensuring raw material purity is crucial for maintaining production standards.

Conclusion

In the manufacturing of ESD Ceramic Arms, understanding their unique properties is crucial for overcoming common challenges such as defects and performance issues. By employing strategic approaches and innovative solutions, manufacturers can enhance the production quality and functionality of these precision components. Effective quality control practices play a vital role in ensuring that each ESD Ceramic Arm meets the required standards, thereby reducing waste and improving overall efficiency.

Looking ahead, the future of ESD Ceramic Arm technology holds exciting developments that promise to further optimize manufacturing processes. At St.Cera Co., Ltd., our dedication to research and development in precision ceramic manufacturing positions us at the forefront of these advancements, allowing us to better serve our clients and contribute to the evolving landscape of ESD ceramic applications.

Related Posts

-

5 Reasons Why the Best 4 Inch Ceramic End Effector is a Game Changer

-

The Future of Innovative Ceramic Cylinder Solutions for Global Trade

-

The Ultimate Guide to Zirconia Ceramic Rods: Unveiling Key Properties and Market Trends

-

How to Choose the Best ESD Wafer Arm for Optimal Semiconductor Processing Efficiency

-

Ultimate Guide to Sourcing the Best Ceramic C-Shape Rings for Global Markets

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

Blog Tags: