Addressing Challenges in High-Precision Manufacturing with Bernoulli Ceramic Finger Technology

Table of Contents

- Challenges in High-Precision Manufacturing: Current Landscape and Trends

- The Role of Bernoulli Ceramic Finger Technology in Reducing Material Waste

- Key Performance Indicators: Measuring the Impact of Precision Technologies

- Case Studies: Success Stories in High-Precision Applications using Bernoulli Technology

- Future Innovations: Emerging Trends in Ceramic Finger Technology for Manufacturing

- Industrial Impact: Statistical Analysis of Efficiency Gains with Advanced Precision Tools

- FAQS

- Conclusion

- Related Posts

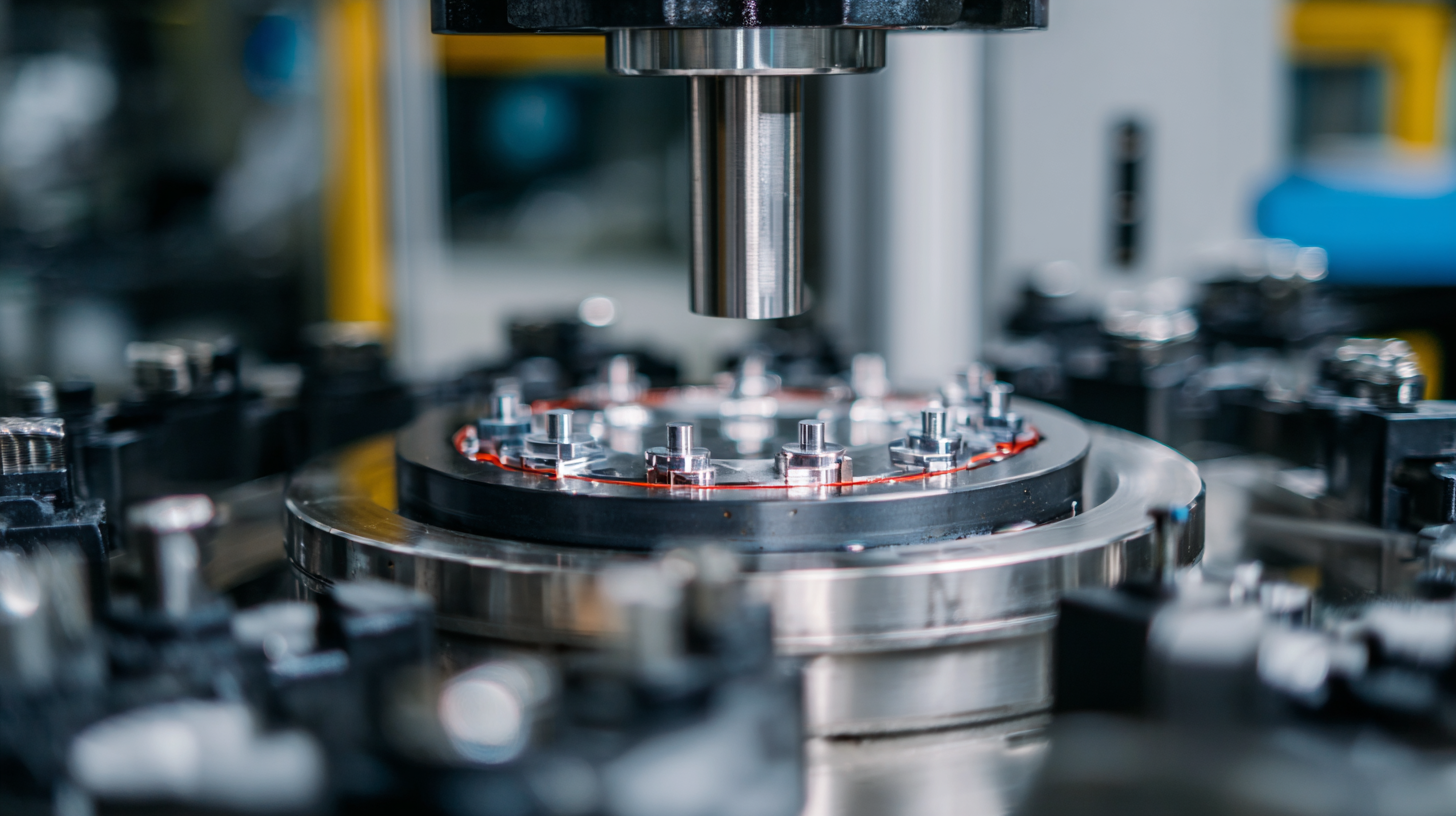

In the realm of high-precision manufacturing, the demand for innovative technologies that enhance performance and accuracy has never been greater. Recent reports indicate that the global precision ceramics market is projected to reach $16.2 billion by 2025, reflecting an annual growth rate of 7.5%. One such groundbreaking innovation is the Bernoulli Ceramic Finger technology, which offers unparalleled precision and efficiency in handling delicate components. As a leader in this field, ST.CERA CO., LTD. harnesses the expertise of top-ranking specialists in precision ceramic manufacturing, positioning itself at the forefront of this technological evolution. The integration of the Bernoulli Ceramic Finger not only addresses the pressing challenges faced in high-precision applications but also propels manufacturers towards achieving superior quality and productivity in an increasingly competitive landscape.

Challenges in High-Precision Manufacturing: Current Landscape and Trends

High-precision manufacturing has become an essential focal point for industries ranging from aerospace to medical devices, where tolerances are measured in microns. However, the current landscape presents several challenges that can hinder production efficiency and product quality. First, the increasing complexity of designs and materials demands advanced machining techniques and tools capable of delivering the required precision. Additionally, the pressure for shorter lead times forces manufacturers to balance speed with accuracy, often leading to compromises in product integrity.

Amidst these challenges, the introduction of Bernoulli Ceramic Finger Technology emerges as a promising innovation. This technology leverages the principles of fluid dynamics to enhance the gripping and handling of delicate components during production. By utilizing Bernoulli effects, manufacturers can reduce the risks of damage and contamination, ensuring higher quality outputs. Furthermore, this advanced technique minimizes mechanical wear and susceptibility to thermal distortion, allowing for stable, sustained high-precision operations even in the face of demanding production schedules. As manufacturers continue to adapt to evolving market requirements, embracing such technologies will be crucial for overcoming the obstacles inherent in high-precision manufacturing.

The Role of Bernoulli Ceramic Finger Technology in Reducing Material Waste

In the realm of high-precision manufacturing, minimizing material waste is crucial for efficiency and cost-effectiveness. Bernoulli Ceramic Finger Technology emerges as a revolutionary solution, specifically designed to address these challenges. Unlike traditional manufacturing tools that often lead to excessive scrap, this innovative technology utilizes fluid dynamics to precisely control the application of manufacturing materials. By optimizing the delivery and usage of specific materials, manufacturers can achieve higher yields and significantly reduce wasted resources.

The inherent properties of ceramics, combined with the Bernoulli effect, allow for enhanced accuracy in material deposition. This means that each component can be crafted with remarkable precision, ensuring that every ounce of material is utilized effectively. Furthermore, the precision of the Bernoulli Ceramic Fingers minimizes the risk of errors during the manufacturing process, which not only saves materials but also time and labor costs associated with rectifying mistakes. As industries continue to seek sustainable practices and elevate product quality, embracing Bernoulli Ceramic Finger Technology stands out as a pivotal advancement for reducing material waste and enhancing operational efficiency.

Key Performance Indicators: Measuring the Impact of Precision Technologies

In the realm of high-precision manufacturing, the integration of advanced technologies such as Bernoulli Ceramic Finger Technology is crucial for enhancing performance metrics. Key performance indicators (KPIs) play a significant role in evaluating the effectiveness of these precision technologies. A recent industry report by McKinsey indicates that companies leveraging high-precision manufacturing technologies can achieve up to a 30% increase in productivity while reducing defects by nearly 25%. These metrics underscore the importance of adopting innovative surface handling solutions to remain competitive.

To maximize the impact of precision technologies, manufacturers should focus on a few essential tips. First, investing in training programs for operators enhances the understanding and usability of new technologies, thereby improving overall production quality. Secondly, regular maintenance and calibration of machinery ensure consistent adherence to precision standards. Lastly, implementing a robust data collection system enables real-time monitoring of KPIs, allowing for timely insights and adjustments that drive continual improvement.

With the right technology and focused strategies, manufacturers can significantly enhance their precision metrics, thereby positioning themselves as leaders in the marketplace and ensuring sustained growth in high-precision sectors.

Addressing Challenges in High-Precision Manufacturing with Bernoulli Ceramic Finger Technology - Key Performance Indicators: Measuring the Impact of Precision Technologies

| KPI | Measurement Unit | Target Value | Current Value | Improvement |

|---|---|---|---|---|

| Dimensional Accuracy | µm | 5 | 6 | -1 |

| Surface Finish Quality | Ra (µm) | 0.3 | 0.4 | -0.1 |

| Production Yield | % | 95 | 90 | -5 |

| Cycle Time | Seconds | 60 | 70 | +10 |

| Cost per Unit | $ | 20 | 22 | +2 |

Case Studies: Success Stories in High-Precision Applications using Bernoulli Technology

In the realm of high-precision manufacturing, Bernoulli Ceramic Finger Technology has emerged as a game-changing solution, addressing various challenges faced in producing intricate components. The technology leverages precise airflow principles to manipulate and handle delicate ceramic parts with unparalleled accuracy. This innovative approach not only minimizes the risk of damage during production but also enhances the overall efficiency of the manufacturing process. Case studies have shown that industries such as aerospace and medical devices have successfully integrated Bernoulli technology, resulting in improved operational performance and product quality.

At ST.CERA Co., Ltd., our dedication to advancing precision ceramic manufacturing aligns perfectly with these successes. Our team of top-ranking experts and engineers is actively involved in the research and development of innovative solutions like Bernoulli technology. By focusing on high-precision applications, we continuously strive to push the boundaries of what is possible in ceramic manufacturing. The integration of cutting-edge technologies not only strengthens our position in the market but also propels our clients to achieve their manufacturing goals with enhanced reliability and precision.

Addressing Challenges in High-Precision Manufacturing with Bernoulli Ceramic Finger Technology

This chart illustrates the success stories in high-precision applications using Bernoulli Technology. The data represents the improvement in manufacturing precision across various applications before and after the implementation of Bernoulli Ceramic Finger Technology.

Future Innovations: Emerging Trends in Ceramic Finger Technology for Manufacturing

Emerging trends in ceramic finger technology are poised to revolutionize high-precision manufacturing processes. As industries increasingly demand precision and efficiency, the adoption of advanced materials like Bernoulli ceramic fingers has gained traction. Recent studies indicate that the global ceramic materials market is expected to reach $290 billion by 2026, with a significant share attributed to manufacturing applications. This growth is fueled by the unique properties of ceramics, such as their high durability, resistance to corrosion, and the ability to maintain precision under varying conditions.

Innovations in ceramic finger technology are also focusing on improving process automation and reducing waste. According to a report by the International Journal of Advanced Manufacturing Technology, the incorporation of smart sensors within ceramic fingers can enhance real-time monitoring and quality control, minimizing defects during production. This integration of Industry 4.0 principles not only boosts operational efficiency but also aligns with sustainability goals, as manufacturers seek to reduce carbon footprints and resource consumption. As these innovations continue to emerge, the landscape of high-precision manufacturing is set to transform, promising notable advancements in reliability and productivity.

Industrial Impact: Statistical Analysis of Efficiency Gains with Advanced Precision Tools

In the realm of high-precision manufacturing, the integration of advanced tools like Bernoulli ceramic finger technology has proven transformative. Recent statistical analyses highlight significant efficiency gains achieved through the use of these innovative precision tools. By leveraging highly engineered materials and sophisticated design, manufacturers have observed not only improved accuracy but also reductions in waste and operational costs. The implications of these findings are profound, as they present a compelling case for the adoption of such technologies in various industrial applications.

Moreover, the real-world impact of Bernoulli ceramic finger technology underscores the importance of data-driven decision-making in manufacturing processes. By analyzing performances before and after implementing these tools, companies have identified key performance indicators that directly reflect productivity enhancements. For instance, metrics such as cycle time, setup time, and product quality have shown marked improvement, demonstrating the efficacy of these tools in optimizing workflows. The statistical outcomes speak volumes, positioning Bernoulli technology as a cornerstone for future innovations in high-precision manufacturing.

FAQS

: Bernoulli Ceramic Finger Technology is an innovative solution in high-precision manufacturing that utilizes fluid dynamics to precisely control the application of manufacturing materials, significantly reducing material waste.

The technology optimizes the delivery and usage of materials, ensuring higher yields and less scrap compared to traditional manufacturing tools.

The inherent properties of ceramics, combined with the Bernoulli effect, enhance the accuracy of material deposition, allowing manufacturers to maximize the usage of every ounce of material.

This technology has been successfully integrated into high-precision applications in industries such as aerospace and medical devices.

The key benefits include reduced material waste, improved operational efficiency, enhanced accuracy in production, and lower labor costs related to correcting errors.

By minimizing the risk of damage during production and ensuring precise handling of delicate parts, Bernoulli Ceramic Finger Technology enhances the overall quality of the manufactured products.

ST.CERA Co., Ltd. focuses on advancing precision ceramic manufacturing and conducts research and development related to innovative solutions like Bernoulli technology.

Adopting sustainable practices is crucial for reducing waste, improving efficiency, and meeting the growing demand for higher product quality in manufacturing processes.

The technology reduces labor costs associated with rectifying mistakes since its precision minimizes the risk of errors during the manufacturing process.

The future looks promising as industries seek to improve efficiency and sustainability, making advancements like Bernoulli Ceramic Finger Technology pivotal in achieving these goals.

Conclusion

The blog "Addressing Challenges in High-Precision Manufacturing with Bernoulli Ceramic Finger Technology" delves into the contemporary obstacles faced in high-precision manufacturing, highlighted by an ever-evolving landscape and trends. It emphasizes how Bernoulli Ceramic Finger technology serves as a pivotal solution to mitigate material waste, thereby enhancing manufacturing efficiency. Key performance indicators are discussed, showcasing the tangible impacts of precision technologies in industrial settings, supported by compelling case studies that illustrate successful applications of Bernoulli technology.

Furthermore, the article explores future innovations and emerging trends in ceramic finger technology, projecting its significant industrial impact through statistical analyses of efficiency gains. As a leader in precision ceramic manufacturing, ST.CERA CO., LTD. is well-positioned to leverage these advancements, thanks to its expertise and commitment to R&D, ultimately driving the next wave of innovation in the manufacturing sector.

Related Posts

-

Choosing the Right Manufacturer for the Best Ceramic Guide Pin: Essential Solutions and Tips

-

How to Choose the Best Sapphire Tube: Essential Metrics and Industry Insights for Global Buyers

-

Innovative Applications of Aluminum Nitride Plates in Modern Technology

-

Innovative Use Cases for Silicon Nitride Ceramic Sleeve in Modern Applications

-

Navigating Global Trade Certifications for Best Al2o3 Ceramic Rod Purchases

-

Top Global Manufacturers of Best Bernoulli Wafer Arm for International Buyers

Blog Tags: