Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

Table of Contents

- The Evolution of Ceramic Centering Rods: A Brief History

- Key Characteristics of Ceramic Centering Rods That Enhance Precision

- Comparing Ceramic Centering Rods to Traditional Materials

- Benefits of Using Ceramic Centering Rods in High-Quality Manufacturing

- Tips for Selecting the Right Ceramic Centering Rod for Your Application

- Maintenance and Care for Longevity of Ceramic Centering Rods

- FAQS

- Conclusion

- Related Posts

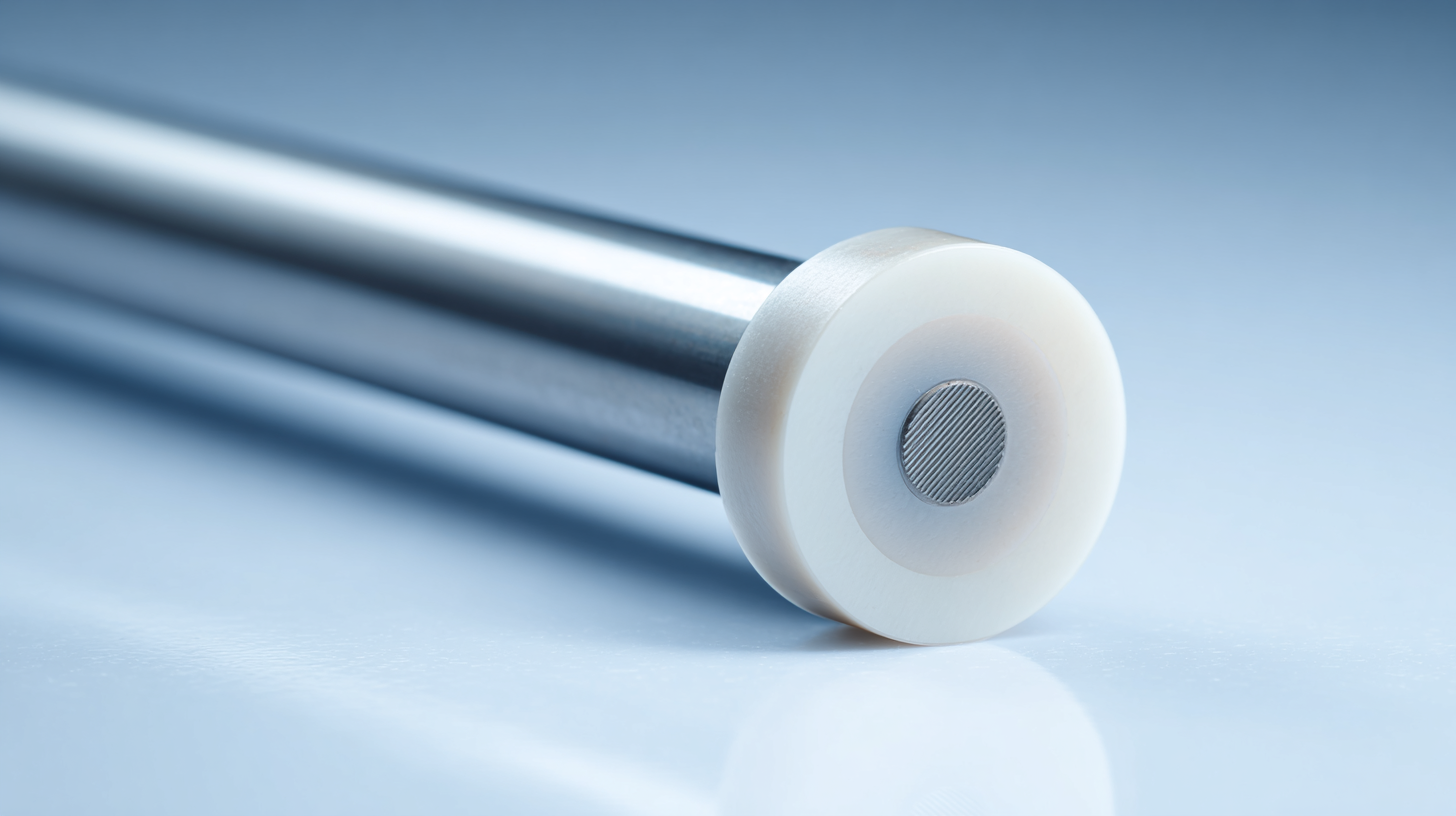

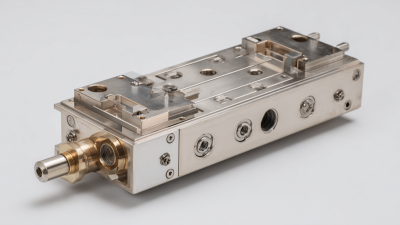

In the world of precision manufacturing, the pursuit of quality and accuracy is paramount, making Ceramic Centering Rods an essential component in various applications. At ST.CERA CO., LTD., we specialize in precision ceramic manufacturing, leveraging our expertise to develop high-quality components that significantly enhance operational efficiency and product reliability. Our team of top-ranking experts and engineers is dedicated to pushing the boundaries of innovation in this field, focusing on the unique advantages that Ceramic Centering Rods offer. This blog will explore the top strategies for optimizing the use of these rods, showcasing how they can unlock new levels of precision and quality in manufacturing processes while reinforcing ST.CERA’s commitment to excellence and cutting-edge technology. As we delve into the benefits and applications of Ceramic Centering Rods, our experience will illuminate their critical role in advancing industry standards.

The Evolution of Ceramic Centering Rods: A Brief History

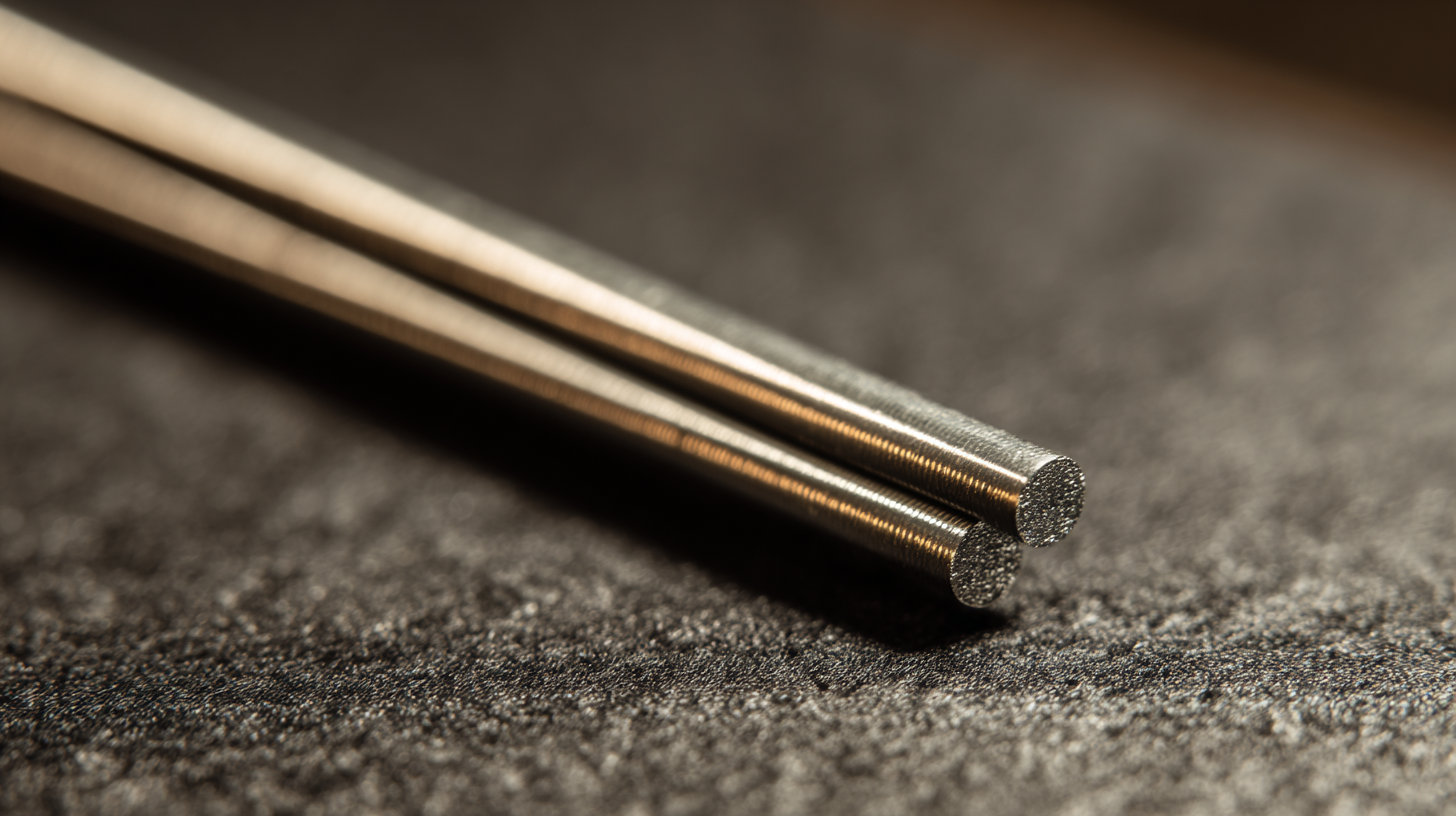

The evolution of ceramic centering rods has transformed the landscape of precision manufacturing. Initially developed for basic applications, these rods have undergone significant advancements, reflecting innovations in material science and engineering. Over time, ceramic centering rods have become essential in industries requiring high tolerance and minimal error, such as aerospace, automotive, and medical device manufacturing. Their lightweight nature, combined with outstanding resistance to wear and corrosion, has propelled them to the forefront of precision components.

At ST.CERA CO., LTD., we pride ourselves on being pioneers in the precision ceramic manufacturing sector. Our dedicated team of experts continuously pushes the boundaries of ceramic technology, ensuring that we provide cutting-edge solutions like ceramic centering rods. By focusing on research and development, we harness the latest advancements to cater to the evolving needs of our clients. The unique properties of our ceramic parts not only enhance precision but also contribute to the overall quality and reliability of manufactured products, solidifying our position as leaders in the industry.

Key Characteristics of Ceramic Centering Rods That Enhance Precision

Ceramic centering rods have become essential in achieving precision and quality in various manufacturing applications. One of their key characteristics is their excellent thermal stability, which allows them to maintain dimensional integrity even under fluctuating temperatures. This property is crucial when working with materials that require a controlled environment to enhance the final product's accuracy.

Furthermore, the low thermal conductivity of ceramic rods minimizes heat transfer, reducing the risk of warping or distortion during processing.

Another significant advantage of ceramic centering rods is their superior mechanical strength. Their robust nature allows them to withstand high levels of stress without compromising their structural integrity, making them ideal for applications in industries ranging from aerospace to medical device manufacturing. Recent advancements in 3D printing technology are further optimizing the production of these ceramic components, enabling the creation of lightweight yet multifunctional structures that enhance performance. Additionally, the integration of deep learning techniques for classification and valuation further underscores the growing importance of ceramics in modern manufacturing processes, highlighting their potential for superior precision and quality in the finished product.

Comparing Ceramic Centering Rods to Traditional Materials

Ceramic centering rods are increasingly being recognized for their advantages over traditional materials like metal and plastic in various applications, including in precision engineering and manufacturing. A recent study highlighted that ceramic materials exhibit superior corrosion resistance and mechanical properties, making them more durable and reliable in challenging environments. For instance, ceramic rods demonstrate a Vickers hardness rating significantly higher than that of conventional materials, indicating their ability to withstand wear and deformation under stress. This translates to longer-lasting components in high-pressure applications, such as insulators and aerospace components.

When considering material choices, one should note that the electrical properties of ceramics also offer superior insulation characteristics compared to traditional materials. This is evident in glass fiber-reinforced epoxy composites, which have shown enhanced performance in high-voltage insulator core rod applications. The dielectric strength of ceramic materials allows for safer and more efficient operation in electrical systems.

**Tip 1:** When selecting materials for applications requiring precision, prioritize ceramics for their stability and longevity.

**Tip 2:** Always evaluate the specific environmental conditions your materials will endure; ceramics may offer advantages in corrosive or high-temperature settings.

**Tip 3:** Consider the long-term cost benefits of ceramics, as their durability can often offset initial higher costs compared to traditional materials.

Benefits of Using Ceramic Centering Rods in High-Quality Manufacturing

Ceramic centering rods have emerged as

indispensable tools in high-quality manufacturing processes, offering remarkable benefits

that enhance precision and overall product

quality. According to recent industry reports, the use of ceramic materials

in manufacturing can lead to a 30% increase in accuracy during

machining operations. This is primarily due to their excellent dimensional stability and

resistance to thermal expansion, which are critical factors in high-precision applications.

Ceramic centering rods have emerged as

indispensable tools in high-quality manufacturing processes, offering remarkable benefits

that enhance precision and overall product

quality. According to recent industry reports, the use of ceramic materials

in manufacturing can lead to a 30% increase in accuracy during

machining operations. This is primarily due to their excellent dimensional stability and

resistance to thermal expansion, which are critical factors in high-precision applications.

Additionally, ceramic centering rods provide superior durability compared to traditional metal

options. They exhibit a hardness level that, according to a study by the U.S. Department of Energy,

can be more than five times greater than that of steel.

This resistance to wear and deformation not only extends the lifespan of tooling equipment but

also significantly reduces maintenance costs. As industries increasingly demand tighter tolerances

and better surface finish, the adoption of ceramic centering rods positions manufacturers to capitalize

on these advantages, ensuring they meet the rigorous standards of modern production.

Tips for Selecting the Right Ceramic Centering Rod for Your Application

When selecting the right ceramic centering rod for your application, several factors come into play to ensure precision and quality. Key considerations include the rod's dimensions, material composition, and the specific operating environment. For instance, ceramic rods made from advanced materials like alumina or zirconia offer superior strength and thermal resistance, making them ideal for high-precision applications in industries such as aerospace and electronics.

At ST.CERA CO., LTD., we understand that the choice of a ceramic centering rod can significantly impact your project's success. Our expertise in precision ceramic manufacturing allows us to provide customized solutions tailored to your unique requirements. Our team of top-ranking experts is dedicated to guiding you through the process of selecting the perfect ceramic centering rod, ensuring that you achieve optimal performance and reliability in your operations. With a focus on research and development, we strive to innovate and enhance the quality of our ceramic components, setting the standard for excellence in the industry.

Maintenance and Care for Longevity of Ceramic Centering Rods

Ceramic centering rods are becoming increasingly favored in precision applications due to their durability and superior performance characteristics. However, to maximize their longevity and maintain their quality, proper maintenance and care are essential. Routine cleaning is critical, as contaminants can lead to wear and degradation over time. Utilizing non-abrasive cleaning solutions ensures that the rods retain their integrity, preventing surface damage that could compromise their precision.

Another important aspect of care is proper storage. When not in use, ceramic centering rods should be stored in a protective case to shield them from physical impacts and environmental factors that could lead to chipping or other forms of damage. Additionally, regular inspections should be conducted to identify any early signs of wear or imperfections. By taking these simple yet effective maintenance steps, users can significantly extend the lifespan of their ceramic centering rods, ensuring consistent performance and reliability in precision tasks.

Advantages of Ceramic Centering Rods for Precision and Quality

This chart illustrates the key advantages of ceramic centering rods in terms of precision, quality, and maintenance, highlighting their performance across various dimensions.

FAQS

: Ceramic centering rods offer superior corrosion resistance, enhanced mechanical properties, and significantly higher Vickers hardness compared to conventional materials, leading to greater durability and reliability in demanding environments.

Ceramics provide excellent insulation characteristics and high dielectric strength, making them safer and more efficient for use in electrical systems, particularly in high-voltage applications.

Key considerations include the rod's dimensions, material composition, and specific operating environment, with advanced materials like alumina or zirconia recommended for high-precision needs.

Ceramic rods are designed to withstand wear and deformation under stress, making them suitable for high-pressure situations such as insulators and aerospace components.

It is advisable to prioritize ceramics for their stability and longevity to ensure precision and quality in your projects.

Yes, the durability and long lifespan of ceramic materials can often offset initial higher costs, making them a cost-effective choice for many applications.

Ceramic materials generally exhibit enhanced performance regarding insulation and strength, making them preferable in high-voltage insulator core rod applications compared to glass fiber-reinforced epoxy composites.

Advanced ceramic materials such as alumina and zirconia offer superior strength, thermal resistance, and longer-lasting performance in high-precision applications in industries like aerospace and electronics.

ST.CERA CO., LTD. provides customized solutions and expert guidance to help customers select the perfect ceramic centering rod for their specific requirements, ensuring optimal performance and reliability.

Conclusion

Ceramic Centering Rods have revolutionized the precision and quality of manufacturing processes. Their evolution highlights significant advancements in material technology, enhancing characteristics like durability, thermal resistance, and dimensional stability. Unlike traditional materials, ceramic centerings rods offer superior performance that ensures accurate alignment in various applications, making them indispensable in high-quality manufacturing settings.

At ST.CERA CO., LTD., we specialize in precision ceramic manufacturing, leveraging our expertise to provide top-notch Ceramic Centering Rods tailored to meet diverse needs. Selecting the right rod involves considering specific application requirements, and proper maintenance can extend their longevity, making them a worthwhile investment for businesses seeking to improve efficiency and product quality.

Related Posts

-

Ultimate Guide to Sourcing the Best Sic Wafer Arm for Your Manufacturing Needs

-

Unmatched Quality: Discover the Excellence of China's Premier Zirconia Ceramic Pin Manufacturer

-

Addressing Challenges in High-Precision Manufacturing with Bernoulli Ceramic Finger Technology

-

How to Choose the Best ESD Wafer Arm for Optimal Semiconductor Processing Efficiency

-

Innovative Applications of Aluminum Nitride Plates in Modern Technology

-

Innovative Use Cases for Silicon Nitride Ceramic Sleeve in Modern Applications

Blog Tags: