7 Best Ceramic Lift Pins for Enhanced Performance in Manufacturing

Table of Contents

- Understanding Ceramic Lift Pins: A Comprehensive Overview

- Key Factors to Consider When Choosing Ceramic Lift Pins

- Top 7 Ceramic Lift Pins for Manufacturing Efficiency

- Comparing Ceramic Lift Pins to Traditional Materials

- Implementing Ceramic Lift Pins for Optimal Performance

- Maintenance Tips for Longevity of Ceramic Lift Pins

- FAQS

- Conclusion

- Related Posts

In the manufacturing industry, the demand for high-performance components has never been more critical, and one such essential element is the Ceramic Lift Pin. According to recent industry reports, the global market for advanced ceramic materials, including lift pins, is projected to reach USD 20 billion by 2025, driven by their exceptional durability and precision in high-stress environments. ST.CERA CO., LTD. stands at the forefront of this innovation, leveraging our expertise in precision ceramic manufacturing to deliver outstanding Ceramic Lift Pins that enhance operational efficiency and performance. With a dedicated team of top-ranking experts and engineers, we focus on the research, development, and marketing of precision ceramic parts, ensuring that manufacturing processes are optimized for reliability and longevity. As industries evolve, the role of Ceramic Lift Pins in reducing wear and tear while increasing productivity is becoming increasingly invaluable, marking them as a key component in the future of manufacturing.

Understanding Ceramic Lift Pins: A Comprehensive Overview

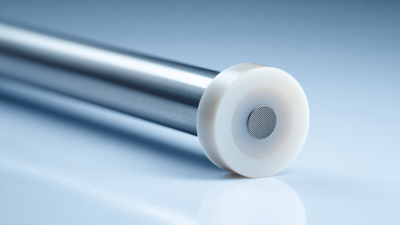

Ceramic lift pins have become an essential component in modern manufacturing processes, offering enhanced performance and durability in various applications. These specialized pins, crafted from advanced ceramic materials, exhibit superior strength-to-weight ratios and exceptional resistance to wear and corrosion. According to a recent market analysis by Technavio, the global ceramic materials market is expected to reach $200 billion by 2025, highlighting the growing reliance on ceramics in manufacturing sectors.

When selecting ceramic lift pins, consider factors such as thermal stability and mechanical properties. For instance, advanced ceramics can withstand high temperatures without compromising their structural integrity, making them ideal for setups where traditional materials would falter. According to a report by Market Research Future, ceramics account for around 30% of the advanced material market due to their unique advantages.

**Tip:** Always verify the compatibility of ceramic lift pins with your specific production environment to ensure optimal performance.

Moreover, the lightweight nature of ceramic lift pins can significantly reduce the energy required for lifting operations. In a case study conducted by the International Journal of Manufacturing Research, manufacturers reported up to a 20% increase in efficiency when integrating ceramic components into their systems.

**Tip:** Regularly assess the performance of your ceramic pins to identify any wear or degradation, ensuring they operate at peak efficiency.

7 Best Ceramic Lift Pins for Enhanced Performance in Manufacturing - Understanding Ceramic Lift Pins: A Comprehensive Overview

| Model | Material | Dimensions (mm) | Temperature Resistance (°C) | Weight (g) | Applications |

|---|---|---|---|---|---|

| Model A | Alumina Ceramic | 10 x 10 x 50 | 1200 | 15 | Electronics, Aerospace |

| Model B | Zirconia Ceramic | 12 x 12 x 40 | 1500 | 18 | Medical Devices, Robotics |

| Model C | Silicon Nitride | 15 x 15 x 30 | 1300 | 20 | Automotive, Manufacturing |

| Model D | Porcelain | 14 x 14 x 35 | 800 | 25 | Household Products, Arts |

| Model E | Alumina Composite | 11 x 11 x 55 | 1250 | 16 | Semi-Conductors, Aerospace |

| Model F | Oxide Ceramic | 13 x 13 x 45 | 1100 | 14 | Electronics, Defense |

| Model G | Cermet | 16 x 16 x 60 | 1400 | 22 | Aerospace, High-Temperature Applications |

Key Factors to Consider When Choosing Ceramic Lift Pins

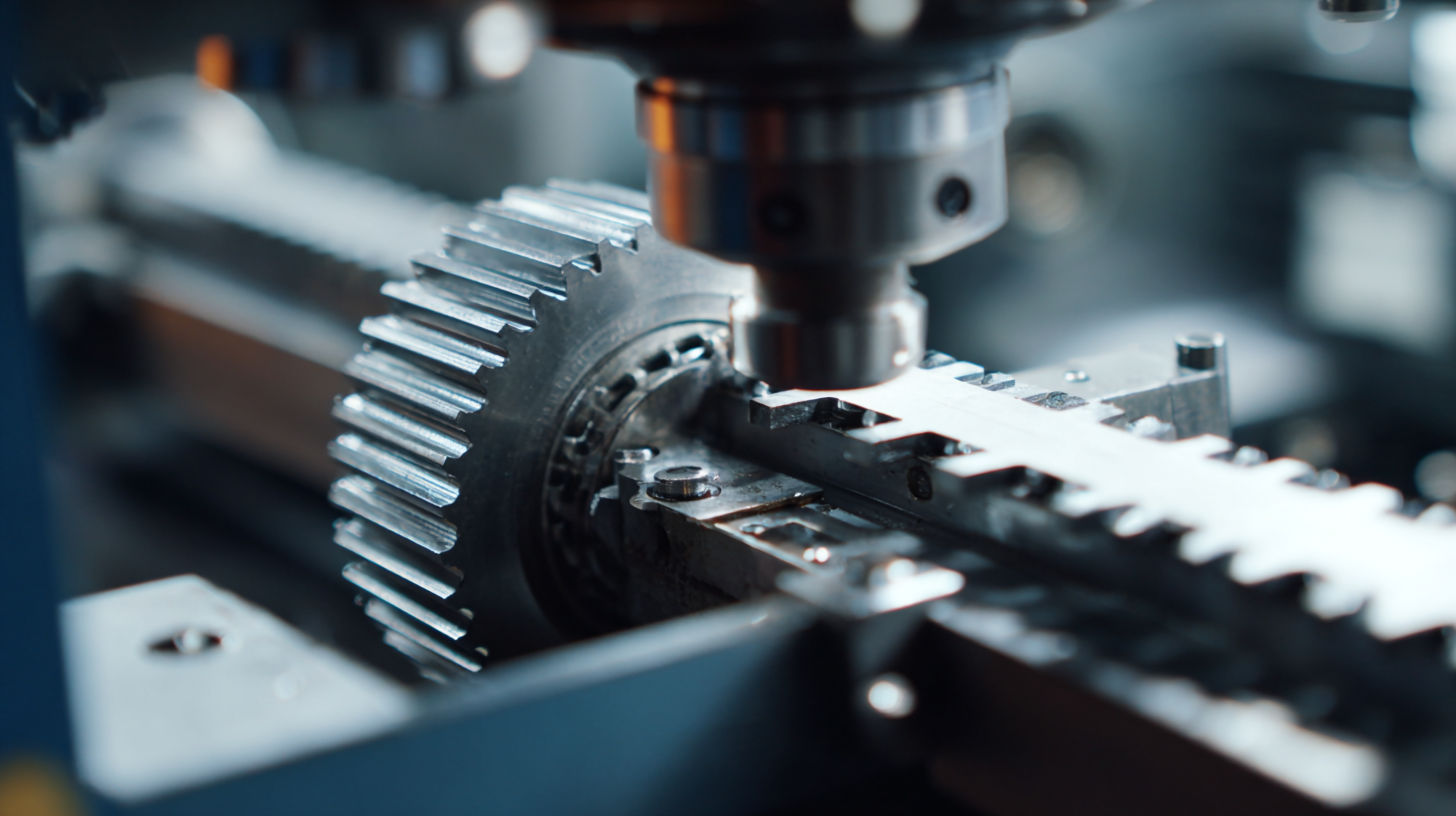

When selecting ceramic lift pins for enhanced performance in manufacturing, several key factors must be considered. First and foremost is the material composition and hardness of the ceramic. Different manufacturing processes require lift pins that can withstand varying levels of heat and mechanical stress. Pins made from high-quality alumina or zirconia ceramics are often preferred due to their exceptional strength and temperature resistance, ensuring longevity and reliability in demanding environments.

Another critical factor is the design and dimensions of the lift pins. The right geometry can significantly influence performance in applications such as injection molding or stamping. It's essential to evaluate the fit and compatibility with existing equipment to avoid operational bottlenecks. Additionally, surface finish plays a vital role in reducing friction and wear, which can ultimately lead to improved cycle times and manufacturing efficiency. Therefore, thoroughly assessing these elements during the selection process can lead to substantial enhancements in productivity and product quality in manufacturing operations.

Top 7 Ceramic Lift Pins for Manufacturing Efficiency

When it comes to enhancing manufacturing efficiency, the choice of lift pins can make a significant difference. Ceramic lift pins have garnered attention for their durability and performance characteristics, providing a reliable option in various industrial applications. The top ceramic lift pins on the market today not only improve the manufacturing process but also contribute to lower maintenance costs, reducing downtime in production lines.

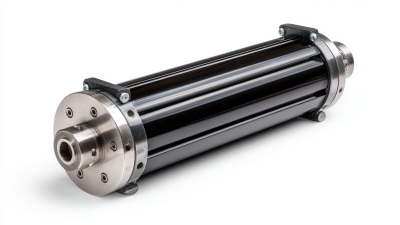

Among the leading options available, some ceramic lift pins stand out due to their high wear resistance and lightweight design. These features allow for smoother operation and longer service life, ensuring that manufacturers can maintain productivity without the frequent need for replacements. Additionally, certain models have been engineered to handle extreme temperatures and corrosive environments, making them suitable for a wide range of manufacturing settings. By selecting the right ceramic lift pins, companies can ensure optimal performance and enhanced efficiency across their operations.

Comparing Ceramic Lift Pins to Traditional Materials

When comparing ceramic lift pins to traditional materials in manufacturing, it's important to highlight the advancements that technical ceramics bring to the table. Traditional materials, such as steel and aluminum, often fall short in terms of durability and resistance to high temperatures. Recent studies have shown that technical ceramics can withstand temperatures over 1000°C, making them ideal for high-performance applications that require minimal thermal expansion and superior wear resistance. The high hardness of ceramic materials not only extends the lifespan of lift pins but also significantly reduces maintenance costs, which is crucial for manufacturers aiming to enhance productivity.

Furthermore, the use of ceramic lift pins can lead to improved operational efficiency. According to industry reports, manufacturers that implement advanced ceramics in their processes have reported efficiency gains of up to 30%. This is due to the reduced friction and better load distribution offered by ceramic lift pins, allowing for smoother operations and less energy consumption. As industries move towards more sustainable manufacturing methods, the transition from traditional materials to ceramic lift pins exemplifies a forward-thinking approach that can enhance performance while reducing environmental impact.

Implementing Ceramic Lift Pins for Optimal Performance

Implementing ceramic lift pins in manufacturing processes can significantly enhance performance and efficiency. Ceramic materials are known for their durability and resistance to wear and tear, which translates into longer tool life and reduced downtime for businesses. According to a report by the Freedonia Group, the global market for ceramic materials is projected to reach $100 billion by 2025, reflecting an increasing reliance on these advanced materials in various industries. By incorporating ceramic lift pins, manufacturers can experience improved load handling and reduced friction, leading to optimized production cycles.

In addition, the operational benefits of ceramic lift pins can directly impact overall production costs. A study conducted by Research and Markets highlights that companies implementing advanced manufacturing technologies, including ceramic components, have reported reductions in maintenance costs by up to 30% and increases in output efficiency by as much as 25%. The superior thermal stability and chemical resistance of ceramic materials allow lift pins to function effectively in harsh environments, ensuring consistent performance and minimal disruption in manufacturing processes. These attributes make ceramic lift pins a valuable investment for companies seeking to improve their manufacturing capabilities.

Maintenance Tips for Longevity of Ceramic Lift Pins

The longevity of ceramic lift pins is crucial for maintaining optimal performance in manufacturing processes. To ensure that these components last, routine maintenance is essential. Start by implementing a regular inspection schedule to check for any signs of wear, damage, or contamination. This proactive approach allows for timely replacements or repairs, preventing costly downtime and maintaining production efficiency.

Another key maintenance tip is to adopt the correct cleaning methods. Using non-abrasive cleaning agents and soft tools minimizes the risk of scratching the ceramic surface. It's also vital to keep the work environment free of debris and other contaminants that could compromise the integrity of the lift pins. Finally, consider storing your ceramic pins in a climate-controlled space to protect them from extreme temperatures and humidity, which can adversely affect their performance and lifespan. By following these maintenance practices, manufacturers can significantly enhance the durability and functionality of ceramic lift pins in their operations.

FAQS

: Ceramic lift pins are specialized components used in manufacturing processes made from advanced ceramic materials, known for their superior strength-to-weight ratios and exceptional resistance to wear and corrosion.

Ceramic lift pins enhance performance and durability in various applications, reducing wear and tear, and improving overall efficiency and tool life in manufacturing operations.

Key factors include the material composition and hardness, design and dimensions, compatibility with existing equipment, and surface finish to minimize friction and wear.

Ceramic materials provide high thermal stability, exceptional strength, and resistance to wear and corrosion, making them suitable for high-temperature and high-stress environments.

The lightweight nature of ceramic lift pins can lead to reduced energy requirements for lifting operations and improvements in load handling, resulting in enhanced production cycles and efficiency.

Yes, businesses using ceramic lift pins have reported maintenance cost reductions of up to 30% and increases in output efficiency by as much as 25%, making them a cost-effective solution.

Pins made from high-quality alumina or zirconia ceramics are often preferred due to their exceptional strength and temperature resistance, ensuring longevity in demanding manufacturing environments.

It is recommended to regularly assess the performance of ceramic pins to identify any wear or degradation, ensuring they operate at peak efficiency throughout their service life.

Conclusion

Ceramic lift pins have become increasingly important in enhancing manufacturing efficiency due to their superior performance characteristics compared to traditional materials. This blog explores the fundamentals of ceramic lift pins, including their unique properties and key factors to consider when selecting them for specific applications. It highlights the top seven ceramic lift pins that stand out in the market, demonstrating their effectiveness in improving operational capabilities.

Moreover, we delve into the advantages of ceramic lift pins over traditional materials, including their durability and precision, which are crucial for optimal performance. Implementing these advanced components in manufacturing processes can lead to significant improvements, while following maintenance tips can ensure their longevity. As a leader in precision ceramic manufacturing, St.Cera Co., Ltd. is committed to providing exceptional ceramic lift pins designed to meet the highest industry standards.

Related Posts

-

The Future of Si3n4 Ceramic Tube Innovations in Industry

-

Ultimate Guide to Choosing the Best Zirconia Ceramic Finger for Your Industrial Needs

-

Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

-

Innovative Use Cases for Silicon Nitride Ceramic Sleeve in Modern Applications

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

7 Essential Tips for Sourcing the Best Silicon Carbide Bushing Globally

Blog Tags: