Unlocking Precision: The Benefits of Using Ceramic Chucks in Manufacturing Processes

Table of Contents

- The Role of Ceramic Chucks in Enhancing Manufacturing Accuracy

- Advantages of Using Ceramic Over Traditional Chuck Materials

- Case Studies: Success Stories in Industries Utilizing Ceramic Chucks

- Comparative Analysis: Ceramic Chucks vs. Other Chuck Types

- Future Trends: Innovations in Ceramic Chuck Technology

- Practical Tips for Implementing Ceramic Chucks in Manufacturing

- FAQS

- Conclusion

- Related Posts

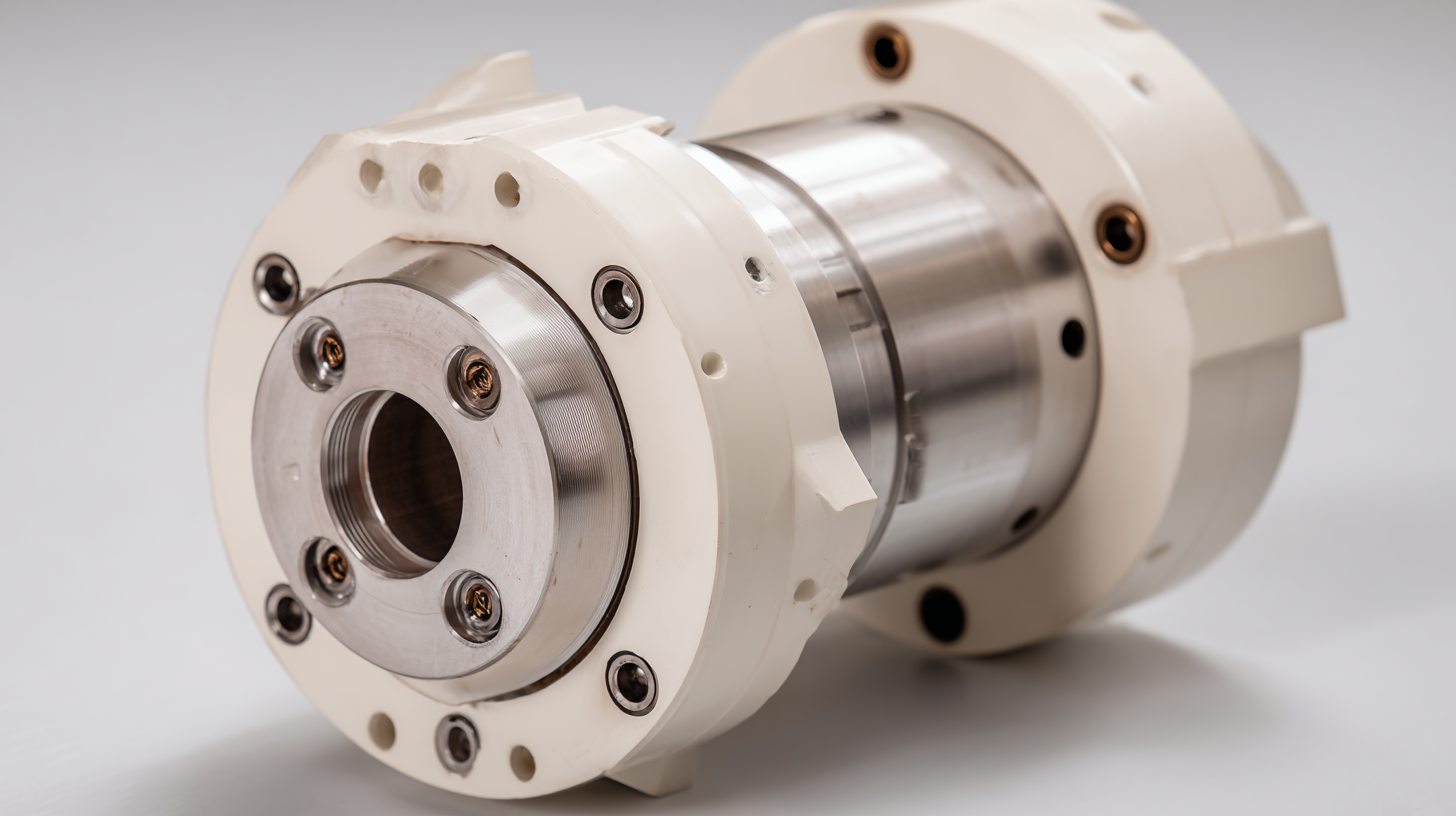

In the rapidly evolving landscape of manufacturing, precision is paramount, and one innovative solution that has gained significant traction is the Ceramic Chuck. At St.Cera Co., Ltd., a private high-tech enterprise dedicated to precision ceramic manufacturing, our team of top-ranking experts and engineers is at the forefront of this technological advancement. Ceramic Chucks offer unparalleled benefits in terms of durability, thermal stability, and precise alignment, making them an invaluable asset in high-precision machining processes. This blog will delve into the transformative capabilities of Ceramic Chucks, exploring their applications and advantages in various manufacturing contexts, and illustrating how St.Cera Co., Ltd. is uniquely positioned to enhance production efficiency through cutting-edge ceramic solutions.

The Role of Ceramic Chucks in Enhancing Manufacturing Accuracy

Ceramic chucks play a pivotal role in enhancing manufacturing accuracy, particularly within the semiconductor industry. With the increasing demand for precision in semiconductor fabrication, the adoption of ceramic chucks has become a game-changer. These components provide superior stiffness and thermal stability, which are crucial for maintaining the tight tolerances required during the manufacturing process. Their electrostatic capabilities further contribute to improved wafer handling and positioning, ensuring that each semiconductor device is crafted with the utmost precision.

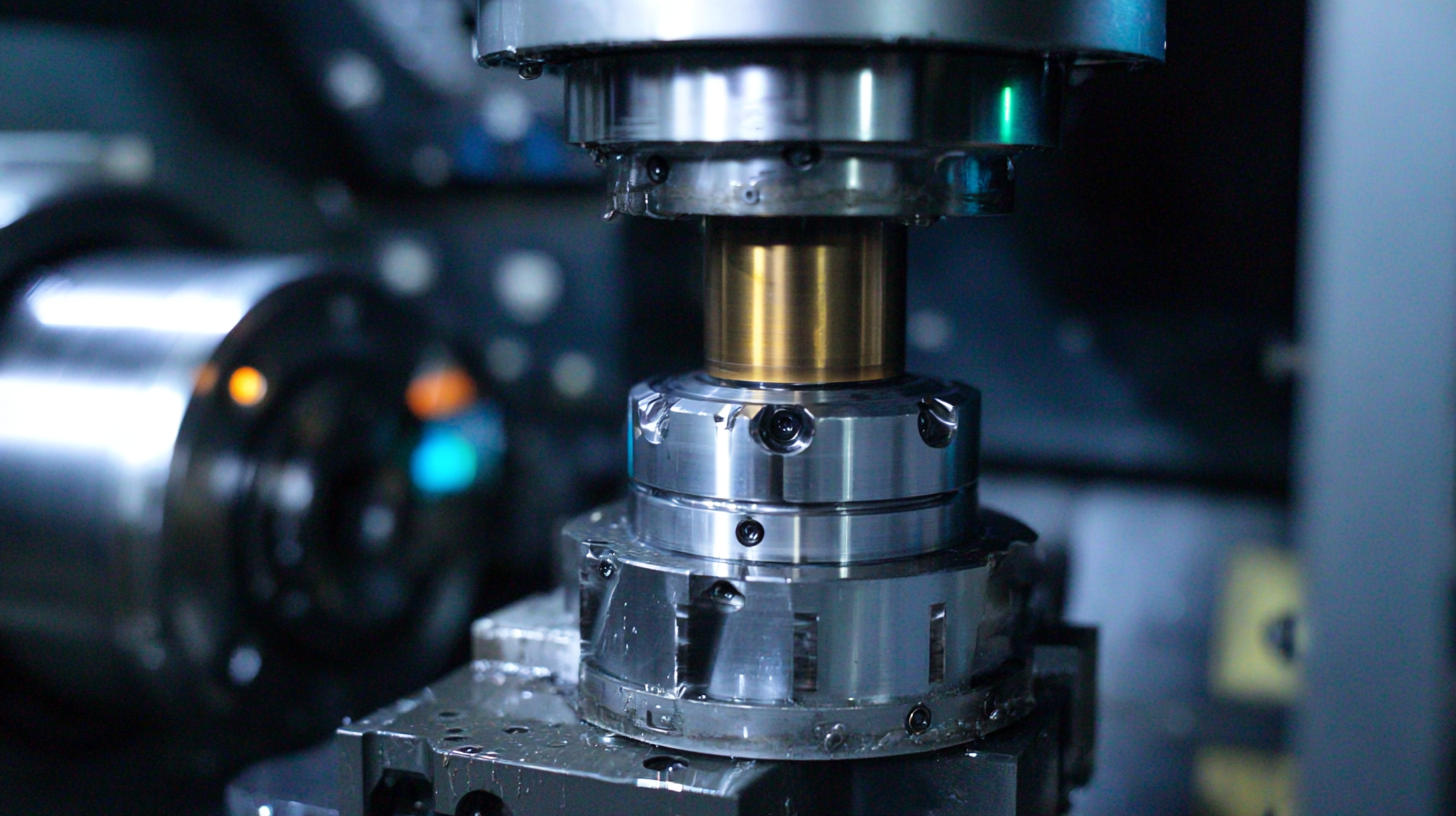

The integration of advanced manufacturing techniques, including the use of ceramic chucks, demonstrates a shift towards more efficient production tools. As the industry continues to evolve, the emphasis on accuracy and reliability in manufacturing processes is essential. The advancements in tools, such as high-speed spindles and innovative handling systems inspired by nature, highlight the importance of precision in achieving optimal performance. The synergy between these technologies and ceramic chucks not only enhances product quality but also drives innovation across various sectors of manufacturing.

Advantages of Using Ceramic Over Traditional Chuck Materials

In manufacturing processes, the choice of chuck materials can significantly influence precision and efficiency. Ceramic chucks have emerged as a superior alternative to traditional steel or aluminum chucks. One of the main advantages of ceramic over conventional materials is its lower weight, which enhances operational speed and reduces the load on machinery. This weight reduction allows for quicker acceleration and deceleration, improving overall productivity on the shop floor.

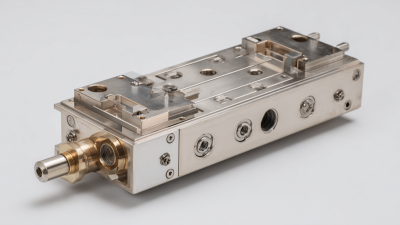

Moreover, ceramic chucks exhibit exceptional hardness and wear resistance, leading to longer tool life and reduced maintenance costs. Their inherent stability under varying temperatures ensures that they maintain dimensional accuracy even in fluctuating environmental conditions. This reliability is crucial for industries that demand tight tolerances and high precision. Additionally, ceramic materials are non-magnetic and non-corrosive, making them ideal for sensitive applications where contamination and material degradation could compromise quality. As manufacturing continues to push the boundaries of precision engineering, ceramic chucks prove to be a forward-thinking choice for businesses aiming to enhance their operational capabilities.

Case Studies: Success Stories in Industries Utilizing Ceramic Chucks

In the world of manufacturing, precision is paramount. Various industries have turned to ceramic chucks to enhance their operational excellence. A noteworthy case study comes from the aerospace sector, where a leading manufacturer adopted ceramic chucks to achieve unprecedented levels of accuracy in component machining. By utilizing the thermal stability and rigidity of ceramic materials, the company reported a significant reduction in tool wear, allowing for longer production runs and minimized downtime. This not only enhanced the quality of the final products but also optimized overall efficiency on the production floor.

Another compelling example can be found in the automotive industry, where ceramic chucks have transformed the way components are manufactured. A renowned automotive supplier replaced their traditional chucks with ceramic alternatives and experienced remarkable improvements in gripping performance and vibration dampening. As a result, they were able to maintain tighter tolerances during machining operations, contributing to the production of high-performance parts. The successful integration of ceramic chucks has enabled manufacturers in various sectors to push the boundaries of precision engineering, yielding substantial gains in both productivity and product quality.

Impact of Ceramic Chucks on Manufacturing Efficiency

This chart illustrates the benefits of using ceramic chucks in manufacturing processes, highlighting key areas such as precision, durability, production speed, and cost efficiency, rated from 1 to 10 based on industry feedback.

Comparative Analysis: Ceramic Chucks vs. Other Chuck Types

The focus on precision in manufacturing has led to a growing interest in ceramic chucks, which offer a range of benefits compared to traditional chuck types. Unlike their steel counterparts, ceramic chucks are known for their remarkable rigidity, lightweight design, and superior thermal stability, which can result in reduced wear and improved performance over time. According to industry reports, the global market for ceramic chucks is anticipated to see a significant increase, driven by advancements in material technology and rising demand for precision-engineered products.

When considering ceramic chucks versus other types, it’s essential to weigh the pros and cons. Ceramic chucks provide better cutting accuracy and maintain tighter tolerances, which can enhance product quality. However, their initial investment can be higher, making it crucial for manufacturers to perform a cost-benefit analysis. Tips on making the right choice include assessing the specific requirements of your manufacturing processes and consulting with industry experts to determine if the advantages of ceramic chucks align with your operational goals.

Additionally, maintaining proper care and handling of ceramic chucks can extend their lifespan and performance. Ensure that chucks are routinely cleaned and inspected for any signs of wear. Implementing preventive maintenance protocols can go a long way in sustaining their operational efficiency, ultimately contributing to enhanced productivity in manufacturing settings.

Future Trends: Innovations in Ceramic Chuck Technology

The landscape of manufacturing is witnessing transformative changes with the emergence of innovative technologies in ceramic chuck design. As industries strive for higher precision and efficiency, advances in materials science are paving the way for next-generation ceramic chucks. These innovative tools are engineered to minimize thermal distortion and enhance machining accuracy, which is essential in fields like aerospace and automotive manufacturing where precision is paramount.

Future trends in ceramic chuck technology focus on integrating smart features, such as sensor applications that monitor real-time performance and wear. This real-time data allows for proactive maintenance, reducing downtime and ensuring optimal functionality. Additionally, advancements in 3D printing techniques are enabling the production of custom ceramic chucks tailored to specific manufacturing needs, further pushing the boundaries of precision engineering. With these innovations, manufacturers are not only elevating their operational capabilities but also fostering a shift towards more sustainable practices by reducing waste and energy consumption.

Unlocking Precision: The Benefits of Using Ceramic Chucks in Manufacturing Processes - Future Trends: Innovations in Ceramic Chuck Technology

| Feature | Ceramic Chucks | Traditional Material Chucks |

|---|---|---|

| Durability | High resistance to wear and thermal shock | Lower resistance; prone to wear over time |

| Weight | Lightweight for easier handling | Heavier, impacting ease of use |

| Precision | Enhanced precision with tighter tolerances | Moderate precision |

| Thermal Conductivity | Lower thermal expansion; stable dimensions | Higher expansion rates |

| Corrosion Resistance | Highly resistant to chemicals | Susceptible to corrosion |

| Future Innovation | Advanced materials and smart technologies | Limited innovation potential |

Practical Tips for Implementing Ceramic Chucks in Manufacturing

Implementing ceramic chucks in your manufacturing processes can significantly enhance precision and efficiency. One practical tip is to evaluate your specific requirements before selection. Different types of ceramic chucks, such as those made from silicon carbide or aluminum oxide, offer unique benefits suitable for various applications. Conducting a thorough analysis of your workpieces and machining methods can help you choose the ideal chuck that meets your operational needs.

Another essential consideration is the proper installation and maintenance of ceramic chucks. Ensure that the chucks are installed with the correct alignment to minimize any runout, which can lead to defects in the final product. Regular cleaning and inspection are also crucial to maintain their performance and longevity. Moreover, investing in training for your workforce regarding the handling and application of ceramic chucks can enhance their usability and ensure that the full range of benefits is realized in your production line.

FAQS

: Ceramic chucks provide superior stiffness and thermal stability, which are crucial for maintaining tight tolerances during the semiconductor fabrication process.

Their lower weight enhances operational speed and reduces the load on machinery, allowing for quicker acceleration and deceleration, thus improving overall productivity.

Ceramic chucks exhibit exceptional hardness and wear resistance, leading to a longer tool life and reduced maintenance costs compared to steel or aluminum chucks.

Ceramic materials are non-magnetic and non-corrosive, making them ideal for applications where contamination and material degradation could compromise quality.

A leading aerospace manufacturer reported significant reductions in tool wear and enhanced accuracy in component machining after adopting ceramic chucks, which resulted in longer production runs and minimized downtime.

An automotive supplier achieved better gripping performance and vibration dampening after replacing traditional chucks with ceramic ones, allowing for tighter tolerances during machining operations.

The integration of ceramic chucks enhances product quality by ensuring precision and reliability in manufacturing processes, which is essential for high-performance parts.

Ceramic chucks maintain dimensional accuracy under varying temperatures, ensuring consistent performance despite fluctuating environmental conditions.

The trend reflects a shift towards more efficient production tools focused on enhancing accuracy and reliability, which is essential for optimal performance in various manufacturing sectors.

The synergy between ceramic chucks and advanced manufacturing techniques, like high-speed spindles, drives innovation and enhances overall performance in precision engineering.

Conclusion

In the manufacturing sector, precision is paramount, and the adoption of Ceramic Chucks is revolutionizing how industries achieve this accuracy. Ceramic Chucks enhance manufacturing processes by providing superior stability and reduced thermal expansion compared to traditional materials. The advantages of using ceramics extend beyond mere precision; they also offer durability and resistance to wear, lowering long-term costs. Companies such as St.Cera Co., Ltd., with its expertise in precision ceramic manufacturing, are at the forefront of this innovation, demonstrating successful implementations across various industries.

Moreover, a comparative analysis with other chuck types showcases the distinct benefits of Ceramic Chucks in achieving better performance and reliability. As technology advances, future trends suggest exciting innovations that will further enhance the capabilities of Ceramic Chucks, making them an essential component in modern manufacturing. For businesses looking to stay ahead, practical tips for integrating Ceramic Chucks into their processes will ensure they reap the full benefits of this cutting-edge technology.

Related Posts

-

The Ultimate Guide to Zirconia Ceramic Rods: Unveiling Key Properties and Market Trends

-

Ultimate Guide to Sourcing the Best Ceramic C-Shape Rings for Global Markets

-

The Future of Innovative Ceramic Cylinder Solutions for Global Trade

-

How to Choose the Best Sapphire Tube: Essential Metrics and Industry Insights for Global Buyers

-

Top Global Manufacturers of Best Bernoulli Wafer Arm for International Buyers

-

Ultimate Guide to Sourcing the Best Sic Wafer Arm for Your Manufacturing Needs

Blog Tags: