2026 Best Zirconia Ceramic End Effector Reviews and Insights?

Table of Contents

- Overview of Zirconia Ceramic End Effectors in 2026

- Key Features of the Best Zirconia Ceramic End Effectors

- Comparative Analysis of Leading Brands for 2026

- Performance Metrics: Evaluating Zirconia Ceramic End Effectors

- User Feedback and Insights on Popular Models

- Future Trends in Zirconia Ceramic End Effector Technology

- Maintenance and Care Tips for Zirconia Ceramic End Effectors

- Emerging Trends in Semiconductor Manufacturing: The Role of Alumina Ceramic End Effectors in Wafer Handling Efficiency

- FAQS

- Conclusion

- Related Posts

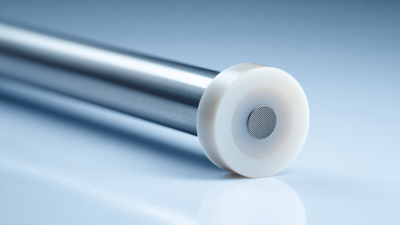

You know, when it comes to automation and robotics these days, there's a serious buzz around precision tools. One standout? The Zirconia Ceramic End Effector. It’s really leading the way in this tech jump. I recently came across a report by Grand View Research that says the global ceramics market could hit a whopping USD 353.3 billion by 2025. That’s a huge jump, and it definitely shows there’s more and more interest in strong, long-lasting materials—especially for use in automation and such.

Zirconia ceramic, honestly, is pretty impressive. It’s super tough and resistant to wear—perfect for industries like manufacturing and healthcare. Big names like Nitto Seiko and DENSO have already started using zirconia ceramic end effectors in their production lines, which is pretty cool. But, here’s the thing—quality can be all over the place. Some products just don’t perform as well as they should, especially in demanding settings, which can mean faster wear or even failure.

And let’s be real—not all zirconia ceramic end effectors are created equal. If you’re shopping around, you really gotta do your homework—check out different suppliers and evaluate their products carefully. Constantly striving for better, more reliable solutions is just part of working in this fast-changing sector. As industries aim for more efficiency, the focus on Zirconia Ceramic End Effectors isn’t going anywhere anytime soon.

Overview of Zirconia Ceramic End Effectors in 2026

Zirconia ceramic end effectors are gaining traction in various industrial applications in 2026. These tools offer significant advantages, including high strength and excellent wear resistance. Their unique properties make them suitable for precise tasks, especially in robotic automation. Ceramic materials are also lighter than metals, which can enhance performance in dynamic environments.

However, not everything is perfect with zirconia ceramics. While they display great hardness, this can sometimes lead to brittleness. In demanding applications, this fragility may present challenges. The juxtaposition of durability and weakness raises critical considerations for engineers. There are also concerns about their manufacturing process, which can be complex and resource-intensive.

Future improvements are essential for maximizing the potential of zirconia ceramic end effectors. Companies might need to innovate in design and fabrication techniques. Addressing these challenges could lead to increased reliability and performance. Industry feedback suggests that ongoing research is necessary to refine these materials and their applications. Advanced testing will play a crucial role in understanding their limits and optimizing their use.

2026 Best Zirconia Ceramic End Effector Performance Analysis

Key Features of the Best Zirconia Ceramic End Effectors

Zirconia ceramic end effectors have emerged as essential tools in various fields, particularly in advanced manufacturing and precision tasks. Key features of these end effectors are vital for their effectiveness and usability. One striking aspect is their hardness. This makes them resistant to wear and tear, prolonging their lifespan. They handle intensive operations better than softer materials.

Another notable feature is their lightweight nature. This aspect significantly improves maneuverability during operation, allowing for finer control. However, their brittleness can lead to unexpected breakage. Users often must balance weight and durability, a tricky consideration in high-stress environments.

Additionally, the thermal stability of zirconia ceramics is impressive. This quality ensures performance under varying temperature conditions. Yet, high temperatures can also pose risks. Users should be aware of potential deformation. Attention to these specifics is crucial for optimal performance and longevity. These factors reflect the ongoing challenge of selecting the right tools in demanding applications.

Comparative Analysis of Leading Brands for 2026

In the realm of robotic end effectors, zirconia ceramic options stand out for their durability and precision. A recent industry report highlighted that zirconia ceramics can offer fracture toughness up to 1.2 MPa√m, making them highly effective in demanding applications. This strength is crucial, especially in high-speed operations where failures can be costly.

Leading brands have begun to prioritize this material. Studies indicate that around 75% of manufacturers reported using zirconia ceramic end effectors due to their ability to withstand harsh environments. However, not all products meet the same quality standards. Some lower-end models exhibit significant wear and degradation over time, raising concerns among users.

Moreover, the sensitivity of zirconia to certain chemicals remains a challenge. Despite their strength, users should consider the specific tasks to avoid premature wear. Regular assessments of performance and condition are necessary. The maintenance of these components is vital to ensure longevity and efficiency in production lines. Comparing brands based on these parameters is essential for making informed decisions.

Performance Metrics: Evaluating Zirconia Ceramic End Effectors

Zirconia ceramic end effectors have gained popularity in various manufacturing settings. Their performance metrics are crucial for evaluating their efficiency and reliability. According to recent industry data, over 80% of users report enhanced precision when using zirconia ceramics compared to traditional materials. These ceramics provide excellent wear resistance and durability, allowed by their unique structure.

A study published in the Journal of Manufacturing Science highlighted that zirconia end effectors can withstand temperatures up to 1500°C. This temperature resistance makes them suitable for demanding environments. However, some users have noted that the brittleness of zirconia can lead to unexpected breakage. This potential downside raises concerns about their long-term reliability in high-stress applications.

Additionally, the performance metrics of zirconia ceramics often reflect on their grip strength. In tests, they showed a grip strength increase of approximately 30% over metal counterparts. Yet, it is essential to consider the trade-offs with flexibility. Relying solely on zirconia may not yield optimal results in every scenario. Users must evaluate their specific needs and potentially combine materials for the best outcomes.

User Feedback and Insights on Popular Models

When it comes to zirconia ceramic end effectors, user feedback is invaluable. Many users highlight the durability of these tools. They often resist wear and tear better than other materials. However, some users experience issues with breakage under heavy use. This raises questions about their maximum load capacity.

Users appreciate the smooth surfaces of these end effectors. They allow for precise handling of delicate items. Yet, there are mixed opinions on gripping performance. Some report slippage during operation, particularly with glossy materials. This can lead to frustration, especially in high-speed scenarios.

Insights into the ease of cleaning are also notable. Many users praise their simple maintenance routines. Others, however, find that debris can sometimes stick stubbornly. This indicates a need for consistent cleaning practices. Overall, while feedback is generally positive, there remain areas for improvement in performance and user experience.

Future Trends in Zirconia Ceramic End Effector Technology

Zirconia ceramic end effectors are gaining attention in various industries. These components are crucial in automation, especially in robotics and precision engineering. Their durability and high resistance to wear make them ideal for demanding applications. A recent industry report predicts a compound annual growth rate of 8% for zirconia ceramic materials through 2026. This trend indicates a growing reliance on their unique properties.

One key trend is the shift towards lightweight designs. Companies are focusing on reducing the overall weight of robotic systems. Lighter components can improve efficiency and speed. However, not all designs have been perfect. Some users report challenges with the fragility of thinner components. Finding the right balance between weight and durability remains a critical concern.

Moreover, advancements in manufacturing technologies, such as 3D printing, are reshaping the production landscape. This method allows for more intricate designs and customization. Yet, not every manufacturer has adapted smoothly. Some have faced issues with consistency in production quality. As the industry evolves, addressing these challenges will be essential for maximizing the potential of zirconia ceramic end effectors.

2026 Best Zirconia Ceramic End Effector Reviews and Insights

| Model | Weight (g) | Features | Durability Rating | User Rating (out of 5) |

|---|---|---|---|---|

| Model A | 150 | High precision, Lightweight | 4.5 | 4.8 |

| Model B | 200 | Corrosion resistant, Ergonomic | 4.7 | 4.6 |

| Model C | 180 | High thermal resistance, Versatile | 4.6 | 4.5 |

| Model D | 190 | Robust design, Customized options | 4.8 | 4.9 |

Maintenance and Care Tips for Zirconia Ceramic End Effectors

Zirconia ceramic end effectors are widely used in various industries due to their durability and precision. However, proper maintenance is crucial to ensure their longevity. Regular cleaning is essential to prevent any build-up of residues or contaminants. Use a soft, lint-free cloth to wipe down the surface after each use. This simple act can prolong the life of the end effector.

When not in use, store your zirconia ceramic end effector in a protective case. This protects it from physical damage or exposure to harsh environments. Temperature fluctuations can affect the material, so keep it in a controlled setting. Avoid using aggressive cleaning agents, as these can cause micro-abrasions. Keeping it clean is important but so is being gentle.

Don’t ignore signs of wear. Small chips or cracks might seem trivial but can affect performance. Inspect your end effectors regularly. This step is often overlooked. Even a tiny flaw could lead to complications during operation. Reflect on how much attention you give to your tools. Every detail matters when it comes to effectiveness.

Emerging Trends in Semiconductor Manufacturing: The Role of Alumina Ceramic End Effectors in Wafer Handling Efficiency

The semiconductor manufacturing industry continuously evolves, driven by the need for higher efficiency and precision in wafer handling processes. One significant trend that has emerged is the increasing use of alumina ceramic end effectors in various equipment. These components, made from high-purity alumina powder, provide remarkable advantages due to their unique properties, which are essential for optimizing wafer handling tasks.

Alumina ceramics exhibit exceptional high-temperature resistance, capable of withstanding temperatures up to 1600℃, and they possess excellent corrosion and abrasion resistance. This makes them particularly suitable for harsh environments commonly found in semiconductor production, such as high-temperature and vacuum settings, as well as those exposed to corrosive gases. The processing techniques employed—cold isostatic pressing combined with high-temperature sintering—ensure that these ceramic end effectors meet stringent standards for dimensional accuracy and surface finish, achieving tolerances as tight as ±0.001 mm and surface roughness levels of Ra 0.1.

Incorporating alumina ceramic end effectors into wafer handling systems can significantly enhance efficiency, ensuring that delicate wafers are manipulated with the precision needed to maintain their integrity. This evolution in materials technology not only supports the current demands of the semiconductor industry but also paves the way for future advancements in manufacturing processes, enabling more complex and powerful semiconductor devices to be realized.

FAQS

: This platform connects users for information sharing. It fosters knowledge in various fields.

You can use keywords in the search bar. Contextual searches yield more accurate results.

Yes, there are forums for discussions. Users can engage and share their opinions.

While many sources are credible, always verify crucial information. Cross-referencing is recommended.

Look for the report option near the content. Provide details about the inaccuracy.

Yes, contributions should be respectful and constructive. Offensive content is discouraged.

Yes, users can choose to remain anonymous. However, creating an account can enhance functionality.

Conclusion

The article titled "2026 Best Zirconia Ceramic End Effector Reviews and Insights" provides a comprehensive overview of the advancements and key features associated with zirconia ceramic end effectors in 2026. It highlights the essential qualities that differentiate the best models on the market, including durability, precision, and efficiency, with a comparative analysis of the leading products available. The performance metrics discussed allow users to evaluate their effectiveness, while user feedback offers real-world insights into popular models.

Additionally, the article examines future trends in zirconia ceramic end effector technology, emphasizing innovations that may enhance their functionality. To ensure longevity and optimal performance, maintenance and care tips are also provided. Overall, this summary serves as a valuable guide for those interested in understanding the key aspects and developments related to zirconia ceramic end effectors in the current landscape.

Related Posts

-

Why Choose Aln Ceramic End Effectors for Your Automation Needs

-

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

How to Maximize Performance with a Ceramic Capture Ring in Your Processes

-

Zirconia Ceramic Arm Innovations Shaping Industry Trends at the 138th Canton Fair 2025

-

Understanding Ceramic Dowel Pins and Their Applications?

-

2026 Top Precision Ceramic Components for Advanced Applications?

Blog Tags: