2026 Top Precision Ceramic Components for Advanced Applications?

Table of Contents

- 2026 Trends in Precision Ceramic Components for Advanced Applications

- Key Properties of Precision Ceramics: Strength, Durability, and Thermal Resistance

- Market Analysis: Growth Predictions for Ceramic Components in Electronics

- Applications of Precision Ceramics in Aerospace and Defense Industries

- Innovative Manufacturing Techniques for Advanced Precision Ceramics

- Impact of Nanotechnology on Ceramic Component Performance and Efficiency

- Regulatory Standards and Certifications for High-Performance Ceramic Products

- FAQS

- Conclusion

- Related Posts

The demand for precision ceramic components is growing rapidly. As industries evolve, high-performance materials become essential. Dr. John Smith, a leading expert at Advanced Ceramics Inc., states, "Precision ceramic components are crucial for achieving reliability in advanced applications."

These components play a vital role in diverse fields, including aerospace and electronics. The unique properties of ceramics, such as high temperature resistance and electrical insulation, contribute to their increasing usage. Yet, the industry faces challenges. Manufacturers often struggle to balance quality with cost-effectiveness.

Innovation is key in this competitive landscape. Companies must explore new techniques and materials to enhance performance. The quest for perfection in precision ceramic components is ongoing, often prompting critical analysis in design and production methods. As the year 2026 approaches, the focus will remain on overcoming these hurdles while delivering outstanding results to meet market demands.

2026 Trends in Precision Ceramic Components for Advanced Applications

The precision ceramic components market is advancing rapidly. By 2026, experts predict a significant growth trajectory. A recent report highlights an expected CAGR of 8.5% in this sector. This surge is driven by automotive and aerospace industries, where lightweight and durable materials are crucial.

Ceramics are sought after for their thermal stability and electrical insulation. These features are vital in advanced applications, such as sensors and semiconductors. However, the supply chain poses challenges. Many companies struggle with sourcing high-quality raw materials. This inconsistency can affect production quality.

Additionally, as demand grows, so does the need for innovation. Companies must explore new designs and manufacturing methods. Traditional techniques may not suffice. The integration of 3D printing technology could reshape how these components are made. While promising, this transition requires time and investment. The industry must tread carefully to embrace these changes while ensuring quality control remains paramount.

Key Properties of Precision Ceramics: Strength, Durability, and Thermal Resistance

Precision ceramics are essential in advanced applications due to their key properties: strength, durability, and thermal resistance. Strength is vital for components used in harsh environments. According to a recent market study, advanced ceramics can withstand loads exceeding 1,000 MPa. This makes them suitable for aerospace, automotive, and medical devices. However, while they excel under compression, they can be brittle. Careful engineering is necessary.

Durability is another significant advantage. Many precision ceramics resist wear and corrosion better than metals. A report indicated that high-purity alumina ceramics have a lifespan that can exceed 50 years under optimal conditions. Yet, their brittleness often leads to unexpected failures. Design engineers must consider potential stress points and load distributions.

Thermal resistance remains a critical factor for high-performance applications. Some ceramic materials can endure temperatures up to 1,600°C. This capability is crucial for electronic components. Yet, they can also face thermal shock. An improperly designed ceramic part could crack or fail under rapid temperature changes. Balancing high-performance properties with practical design challenges is essential for the future.

Market Analysis: Growth Predictions for Ceramic Components in Electronics

The market for precision ceramic components in electronics is witnessing significant growth. According to a report by Grand View Research, the global ceramics market is projected to reach $185 billion by 2026. This surge is driven by advancements in technology and increased demand for high-performance materials.

Ceramic components play a crucial role in various electronic devices. They are used in capacitors, insulators, and substrates. These materials offer excellent thermal stability and electrical insulation. The rising need for smaller, faster, and more efficient electronic devices supports this trend. For instance, the miniaturization of components in smartphones has increased ceramic's relevance in manufacturing processes.

However, challenges exist in this sector. Manufacturing precision ceramics can be costly and complex. Quality control issues may arise during production. Additionally, the market faces competition from alternative materials. Nonetheless, as more industries seek reliable, efficient solutions, the potential for precision ceramics remains vast. Continued innovation will be essential to overcoming these hurdles and capitalizing on the growing demand.

2026 Top Precision Ceramic Components for Advanced Applications

| Component Type | Market Size (USD Million) | Growth Rate (%) | Key Applications |

|---|---|---|---|

| Ceramic Capacitors | 500 | 8.5 | Consumer Electronics, Automotive |

| Ceramic Insulators | 320 | 7.2 | Telecommunications, Power Equipment |

| Ceramic Substrates | 450 | 9.0 | LEDs, RF Devices |

| Ceramic Resistors | 280 | 6.5 | Industrial Equipment, Precision Devices |

| Ceramic Filters | 220 | 8.0 | Wireless Communication, Audio Equipment |

Applications of Precision Ceramics in Aerospace and Defense Industries

Precision ceramics are making significant strides in aerospace and defense industries. These materials offer exceptional properties such as high strength and thermal resistance. For instance, alumina ceramics are increasingly used in aircraft components due to their lightweight nature. This helps improve fuel efficiency and overall performance. Reports indicate that the global market for aerospace ceramics is projected to reach $4.5 billion by 2026.

In defense applications, precision ceramics are vital. They are used in armor systems and sensor technologies. Ceramic materials can withstand extreme temperatures and pressures. A recent study highlighted that the use of ceramics in military gear can reduce weight by up to 30%. However, challenges remain in the consistency of material quality. There are concerns about defects in ceramic components affecting durability.

Advanced applications in these fields underscore the need for innovation. Continuous improvements in manufacturing processes are crucial. The use of additive manufacturing holds promise. This can potentially enhance the precision of ceramic components. Therefore, ongoing research and development efforts are essential. Optimizing these materials could lead to significant advances in aerospace and defense technologies.

Innovative Manufacturing Techniques for Advanced Precision Ceramics

Precision ceramics are essential in many advanced applications today. The demand for these components is rising due to their unique properties. They offer high strength, temperature resistance, and chemical stability. However, producing them involves complex techniques.

Innovative manufacturing techniques are pushing the boundaries of what precision ceramics can achieve. Techniques like additive manufacturing and nano-engineering open new avenues. These methods allow for intricate designs that were previously impossible. Despite these advancements, challenges remain. The consistency of material properties can vary, introducing potential weaknesses. Quality control is crucial in this process.

Advanced ceramics often require tailored processing methods. Each application may need specific adjustments in temperature and pressure. Understanding these nuances is vital for success. There's always room for improvement in techniques. Innovation should be coupled with critical analysis to ensure better outcomes. Embracing both progress and reticence in manufacturing can lead to more robust solutions.

Impact of Nanotechnology on Ceramic Component Performance and Efficiency

The advent of nanotechnology has brought transformative impacts on the performance and efficiency of precision ceramic components. In advanced applications, these components must endure extreme conditions and provide exceptional reliability. Research shows that incorporating nanoparticles into ceramic matrices can increase mechanical strength by up to 200%. This enhancement supports sectors like aerospace and medical devices, where performance is critical.

Tips: Consider integrating nanomaterials into your ceramic formulations. This could enhance functionality and longevity, particularly in high-stress applications.

However, challenges remain. Not all ceramic materials respond uniformly to nanotechnology. Some combinations may degrade under specific conditions. Continuous testing is essential to ensure the desired outcomes match industry standards.

Remember, the market for advanced ceramic components is projected to reach $16 billion by 2026, reflecting the demand for high-performance materials. Collaborating with researchers and material scientists can help address these uncertainties and improve product consistency.

Regulatory Standards and Certifications for High-Performance Ceramic Products

The demand for high-performance ceramic components is growing rapidly. As industries strive for precision in their applications, regulatory standards become crucial. These standards ensure that products meet safety, reliability, and environmental requirements. According to a recent industry report, the global market for precision ceramics is expected to grow at a CAGR of 6.2% by 2026.

Compliance with regulations is not straightforward. Different regions have varying standards that can affect manufacturing. For example, the ISO 13006 outlines the specifications for ceramic tiles, impacting their performance in construction. Adhering to such regulations not only preserves quality but also protects consumers.

Tips: Always check your supplier’s certifications. Ensure they comply with relevant standards. This can prevent future legal issues.

Quality assurance is essential. Regular testing and validation processes are necessary to meet regulatory requirements. Nevertheless, budget constraints can impair comprehensive testing. Some manufacturers might overlook less critical standards. This could lead to challenges in product performance down the line. It’s vital to address these gaps for long-term success.

Tips: Invest in training for your team. Knowledge of regulations can save costs. Keeping updated helps maintain product integrity.

FAQS

: Take a break. Step outside for fresh air. Breathe deeply and clear your mind.

Set small goals. Focus on one task at a time. Limit distractions in your workspace.

Exercise regularly. Find a hobby you enjoy. Talk to someone about your feelings.

Start with one habit. Track your progress daily. Reward yourself for small achievements.

It helps recharge your energy. It improves mental health. Ignoring it can lead to burnout.

Reflect on what went wrong. Learn from your mistakes. It’s part of growth and improvement.

Revisit your goals. Break tasks into smaller steps. Surround yourself with positive influences.

Embrace the unknown. Focus on what you can control. Stay flexible and open-minded.

Believe in your ability to learn. View challenges as opportunities. Appreciate effort, not just results.

Conclusion

The article "2026 Top Precision Ceramic Components for Advanced Applications" explores the emerging trends and key characteristics of precision ceramic components that are essential for advanced applications in various industries. It highlights critical properties such as strength, durability, and thermal resistance, which position precision ceramics as vital materials in sectors like electronics, aerospace, and defense. The market analysis anticipates significant growth in ceramic components, driven by their increasing adoption in high-performance applications.

Additionally, the article emphasizes the innovative manufacturing techniques that enhance the performance and efficiency of these components, particularly through the integration of nanotechnology. As the demand for precision ceramic components rises, there is also a focus on adhering to regulatory standards and certifications that ensure the quality and reliability of high-performance ceramic products in the market.

Related Posts

-

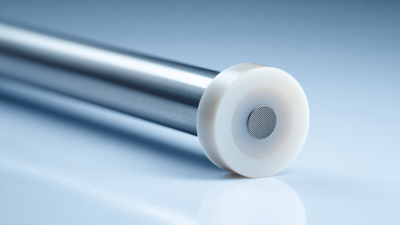

Unlocking the Advantages of Ceramic Centering Rods for Precision and Quality

-

Why Choose Aln Ceramic End Effectors for Your Automation Needs

-

Addressing Challenges in High-Precision Manufacturing with Bernoulli Ceramic Finger Technology

-

How to Maximize Performance with a Ceramic Capture Ring in Your Processes

-

10 Best Precision Ceramic Components for High Performance Applications

-

Top Tips for Choosing Quality Ceramic Spare Parts for Your Needs

Blog Tags: