2025 Top Applications for Alumina Ceramic End Effectors in Robotics Industry

Table of Contents

- Overview of Alumina Ceramics in Robotics

- Properties of Alumina Ceramic Materials for Robotics Applications

- Key Advantages of Using Alumina Ceramic End Effectors

- 2025 Market Trends: Demand for Alumina Ceramic in Robotics

- Applications of Alumina Ceramic End Effectors in Industrial Robotics

- Innovative Designs of Alumina Ceramic End Effectors in Robotics

- Challenges and Future Prospects for Alumina Ceramics in Robotics

- FAQS

- Conclusion

- Related Posts

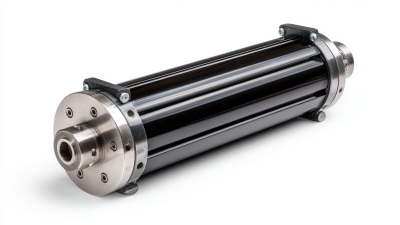

The robotics industry has experienced significant advancements in recent years, with a growing emphasis on enhancing the precision and efficiency of robotic applications. One critical component in this evolution is the Alumina Ceramic End Effector, renowned for its exceptional mechanical properties and versatility. With its unique advantages, including high wear resistance, thermal stability, and reduced weight, Alumina Ceramic End Effectors are increasingly being adopted in various robotic systems, ranging from industrial automation to delicate assembly tasks.

As we look forward to 2025, the role of Alumina Ceramic End Effectors is poised to expand further, driven by the demand for more robust and agile robotic solutions. The ability to tailor these end effectors for specific applications, such as in handling sensitive materials or operating in extreme environments, underscores their importance in the future of robotics. This paper aims to explore the top applications of Alumina Ceramic End Effectors, highlighting how they are transforming operations across diverse sectors, and examining the technological innovations that are influencing their design and functionality. Whether in improving production lines or facilitating complex surgical procedures, the potential of Alumina Ceramic End Effectors in the robotics industry is bound to redefine operational standards and propel future developments.

Overview of Alumina Ceramics in Robotics

Alumina ceramics have emerged as a pivotal material in the robotics industry, particularly in the development of end effectors. These ceramic components are renowned for their exceptional hardness, wear resistance, and thermal stability, making them ideal for environments that demand precision and durability. According to industry reports, the global alumina ceramics market is expected to reach approximately $7.5 billion by 2025, with significant contributions coming from the robotics sector. The ability of alumina ceramics to withstand extreme conditions—temperatures exceeding 1,600°C and significant mechanical stress—positions them as a fundamental material for robotic applications, especially in manufacturing and automation.

In addition to durability, alumina ceramics are also lightweight, which enhances the efficiency of robotic systems. The low density of alumina allows for the design of agile and highly responsive robotic arms capable of handling complex tasks with reduced energy consumption. A report by Grand View Research indicates that the demand for lightweight materials in robotic applications is set to grow by over 20% annually, underscoring the importance of alumina ceramics in enhancing robotic performance. Furthermore, the superior electrical insulating properties of alumina ceramics open up opportunities for their use in sophisticated robotic systems that incorporate sensors and electronic components, paving the way for innovations in both robotic designs and functionalities.

Properties of Alumina Ceramic Materials for Robotics Applications

Alumina ceramic materials possess several remarkable properties that make them highly suitable for use in the robotics industry, particularly in the development of end effectors. One of the key characteristics of alumina ceramics is their exceptional hardness, which allows them to withstand wear and tear in abrasive environments. This durability ensures the longevity of robotic components and reduces maintenance needs, making them an attractive option for manufacturers looking to enhance the efficiency of their robotic systems.

In addition to hardness, alumina ceramics exhibit impressive thermal stability and resistance to high temperatures. This property is particularly beneficial in applications where end effectors are exposed to fluctuating thermal conditions or require operation in extreme heat environments. Furthermore, alumina materials are chemically inert, making them resistant to many corrosive substances. This resilience not only extends the functional lifespan of robotic components but also allows the technology to be deployed in a wider range of industrial contexts, from manufacturing to assembly and beyond.

2025 Top Applications for Alumina Ceramic End Effectors in Robotics Industry

| Application Area | Description | Key Properties | Benefits |

|---|---|---|---|

| Automotive Assembly | Used in robotic arms for precision assembly. | High hardness, wear resistance. | Improved longevity of end effectors. |

| Electronics Manufacturing | Handling sensitive electronic components. | Electrical insulation, thermal stability. | Reduced risk of component damage. |

| Food Industry | Used for packaging and processing food. | Non-reactive, easy to clean. | Safe for food contact applications. |

| Medical Robotics | Robotic arms for surgical applications. | Biocompatibility, sterilization capability. | Enhanced patient safety and hygiene. |

| Aerospace Automation | Assembly of aircraft components. | Lightweight, high strength. | Fuel efficiency and structural integrity. |

Key Advantages of Using Alumina Ceramic End Effectors

Alumina ceramic end effectors are rapidly gaining traction in the robotics industry due to their unique combination of properties that enhance robotic functionality and performance. One of the key advantages of using alumina ceramics is their exceptional hardness and wear resistance, making them particularly suitable for applications that involve high abrasion or harsh environments. According to a report by MarketsandMarkets, the global market for advanced ceramics, including alumina, is projected to reach $125 billion by 2025, driven by the rising demand for high-performance materials in robotics and automation.

Another significant benefit of alumina ceramic end effectors is their lightweight nature, which contributes to improved energy efficiency in robotic systems. A study published in the Journal of Robotics and Automation demonstrates that lighter end effectors not only reduce the energy required for operation but also increase the overall speed and agility of robotic movements. Moreover, alumina ceramics possess excellent thermal stability and chemical resistance, which allows them to maintain performance under extreme temperatures and corrosive conditions, further expanding their application scope in various industrial settings.

The ability of alumina ceramic end effectors to withstand wear, combined with their lightweight and resilient properties, positions them as a vital component in the future of robotic technologies. As industries continue to seek more durable and efficient solutions, the adoption of these advanced materials is expected to play a crucial role in the evolution of robotic end effectors.

2025 Top Applications for Alumina Ceramic End Effectors in Robotics Industry

2025 Market Trends: Demand for Alumina Ceramic in Robotics

The demand for alumina ceramic end effectors in the robotics industry is poised to rise significantly in 2025. As robotics applications continue to advance across various sectors, the unique properties of alumina ceramics, such as their high hardness, wear resistance, and thermal stability, make them ideal candidates for end effector components. These characteristics are critical for robots that operate in demanding environments, such as manufacturing plants and assembly lines, where durability and precision are essential.

As we move into 2025, several market trends are shaping the demand for alumina ceramic in robotics. One key trend is the increasing emphasis on lightweight materials that do not compromise strength or performance. Alumina ceramics provide a promising solution, allowing for the design of lighter, more efficient robotic systems. Additionally, the ongoing development of automation technologies and the push for smarter robots have led manufacturers to explore materials that enhance functionality while reducing maintenance costs.

Tips: When considering the implementation of alumina ceramic components in robotic systems, assess the specific application requirements. Different grades of alumina ceramics offer varying properties and benefits, so optimizing material selection based on operational conditions can significantly enhance performance and longevity. Furthermore, collaborating with material scientists can lead to innovative designs that harness the full potential of alumina ceramics in robotics.

Applications of Alumina Ceramic End Effectors in Industrial Robotics

Alumina ceramic end effectors are increasingly becoming a preferred choice in the industrial robotics sector due to their unique properties, which make them well-suited for a variety of applications. One of the most significant advantages of alumina ceramics is their exceptional hardness and wear resistance, which ensures longevity in high-demand environments. These traits make alumina ceramic end effectors ideal for material handling applications, where durability is crucial for optimizing operational efficiency and reducing downtime caused by equipment failure.

Another key application of alumina ceramic end effectors is in precision assembly tasks. Their lightweight nature combined with excellent thermal stability allows for delicate handling of components, minimizing the risk of damage during assembly processes. Moreover, the biocompatible properties of alumina ceramics make them suitable for use in automated systems within industries such as food processing and pharmaceuticals, where hygiene and cleanliness are paramount. As the robotics industry continues to evolve, the integration of alumina ceramic end effectors will likely expand, enhancing the capabilities and applications of robotic systems across various sectors.

Innovative Designs of Alumina Ceramic End Effectors in Robotics

The innovative designs of alumina ceramic end effectors are revolutionizing the robotics industry by enhancing functionality and durability. These end effectors, characterized by their lightweight and high wear resistance, allow robots to perform tasks with precision, especially in applications requiring clean and sterile environments. The unique properties of alumina, such as its excellent thermal stability and resistance to corrosion, make it an ideal material for handling delicate materials, including electronics and pharmaceuticals. Designers are continuously exploring ways to integrate these ceramics into various robotic architectures, thus pushing the boundaries of what robots can achieve.

Furthermore, the adaptability of alumina ceramic end effectors lays the groundwork for bespoke solutions tailored to specific industry needs. Engineers are increasingly focusing on optimizing geometries and surface textures to improve grip and handling characteristics. Innovative designs may incorporate multi-functional capabilities, allowing a single end effector to perform different tasks by changing its operational state. This versatility not only enhances productivity but also reduces costs associated with maintaining multiple types of end effectors. As these cutting-edge designs emerge, they promise to redefine operational efficiencies across diverse sectors in the robotics landscape.

Challenges and Future Prospects for Alumina Ceramics in Robotics

The integration of alumina ceramic end effectors in the robotics industry promises significant advancements; however, challenges remain that could impact their widespread adoption. One of the main hurdles is the inherent brittleness of alumina materials, which, although they offer high strength and excellent thermal stability, can lead to failures under dynamic loading conditions. To mitigate this, researchers are exploring composite materials that incorporate alumina to enhance toughness while maintaining its desirable properties.

Tips: When considering alumina ceramics for robotic applications, it's essential to evaluate the operational environment. Factors such as temperature fluctuations, exposure to harsh chemicals, and mechanical stress should be analyzed to ensure compatibility and longevity of the end effectors.

Looking to the future, the development of advanced manufacturing techniques, like additive manufacturing and precision machining, could revolutionize the way alumina ceramics are utilized in robotics. These innovations will enable the production of more complex geometries that can optimize performance and minimize waste. As the industry evolves, collaboration between material scientists and robotics engineers will be crucial to overcoming existing challenges and harnessing the full potential of alumina ceramics in automation technologies.

Tips: Stay updated with the latest research and technological advancements in ceramics and robotics to remain competitive in the industry. Networking with professionals in academia and industry can provide insights into innovative solutions and applications.

FAQS

: The demand is driven by the unique properties of alumina ceramics, such as high hardness, wear resistance, and thermal stability, which are ideal for the demanding environments robots operate in, such as manufacturing and assembly lines.

Alumina ceramics allow for the creation of lightweight robotic systems that do not compromise on strength or performance, thereby improving efficiency.

The ongoing development of automation technologies has prompted manufacturers to seek materials that enhance robot functionality while lowering maintenance costs, making alumina ceramics an attractive option.

It is essential to assess specific application requirements and select appropriate grades of alumina ceramics based on operational conditions to optimize performance and longevity.

Alumina ceramic end effectors are known for their exceptional hardness and wear resistance, ensuring longevity and optimizing operational efficiency in high-demand environments.

They are especially effective in material handling for their durability and in precision assembly tasks due to their lightweight and thermal stability properties.

The biocompatible properties of alumina ceramics make them suitable for automated systems in these industries where hygiene and cleanliness are crucial.

As the robotics industry evolves, the integration of alumina ceramic end effectors is likely to expand, enhancing the capabilities and applications of robotic systems across various sectors.

Conclusion

The article "2025 Top Applications for Alumina Ceramic End Effectors in Robotics Industry" explores the significance of alumina ceramics in enhancing robot functionality. It begins with an overview of alumina ceramics, highlighting their unique properties that make them suitable for robotics applications. The key advantages of using Alumina Ceramic End Effectors include their durability, lightweight characteristics, and resistance to wear and corrosion, making them ideal for various industrial tasks.

As demand continues to grow, the article discusses emerging market trends and innovative designs that are shaping the future of alumina ceramic in robotics. Despite facing challenges, such as manufacturing complexities, the potential for alumina ceramic end effectors remains strong, driving the development of advanced robotic systems and applications across diverse industries.

Related Posts

-

7 Best Ceramic Lift Pins for Enhanced Performance in Manufacturing

-

Exploring the Versatility of Alumina Ceramic Rings in Modern Technology Applications

-

Unlocking the Future of Precision Ceramic Parts in High Performance Applications

-

Ultimate Checklist for Sourcing the Best Beo Ceramic Tube for Your Business Needs

-

The Ultimate Guide to Ceramic End Effectors Benefits and Applications

-

Top Benefits of Using Alumina Ceramic End Effectors in Robotics Applications

Blog Tags: